Portable fuse disassembling and combining machine

It is a combined machine and portable technology, which is applied in the direction of weapon accessories, ammunition, offensive equipment, etc. It can solve the problems of performance degradation, poor maneuverability, fuze decomposition and combination, etc., and achieve the effect of compact structure, easy portability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

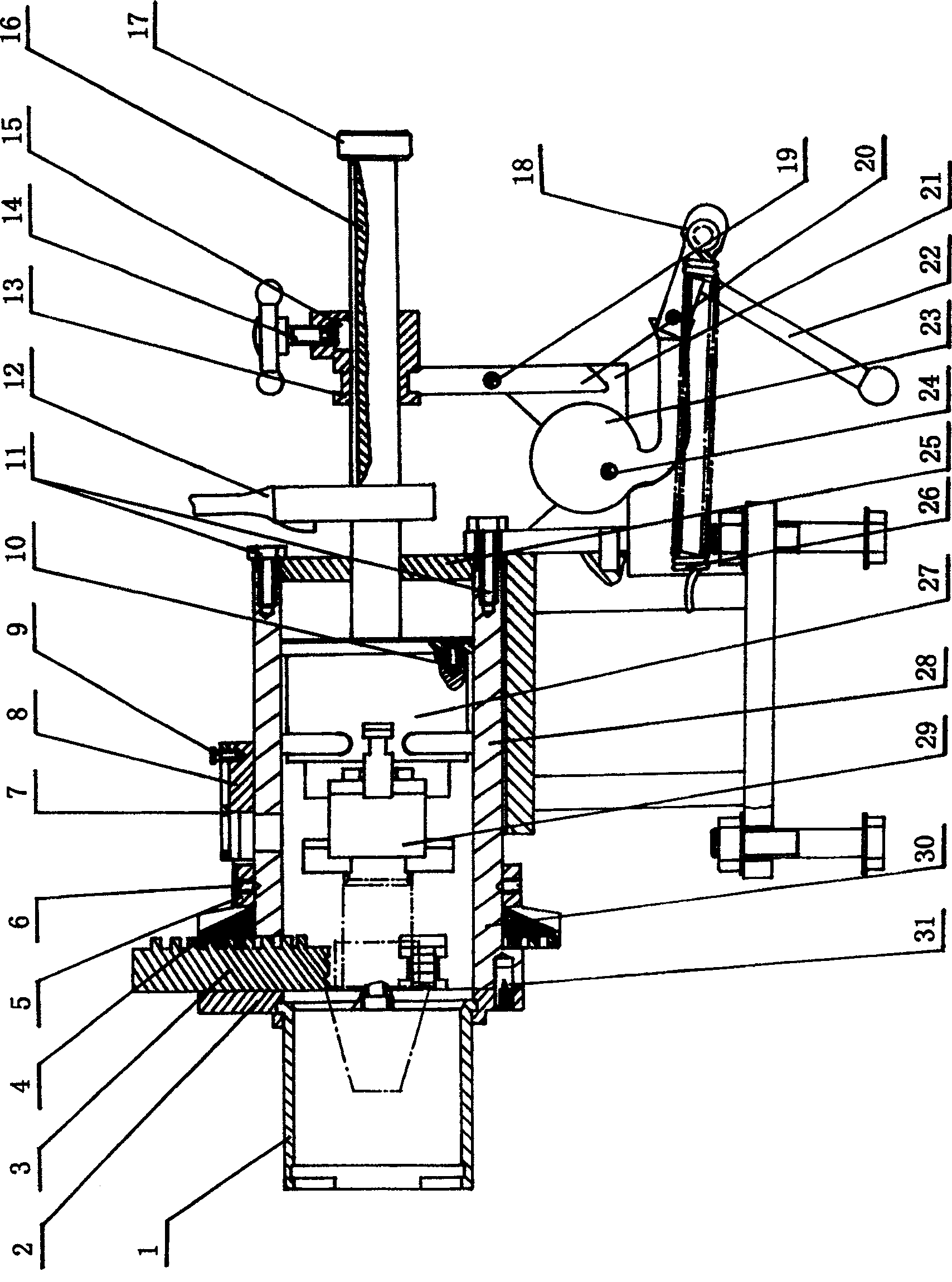

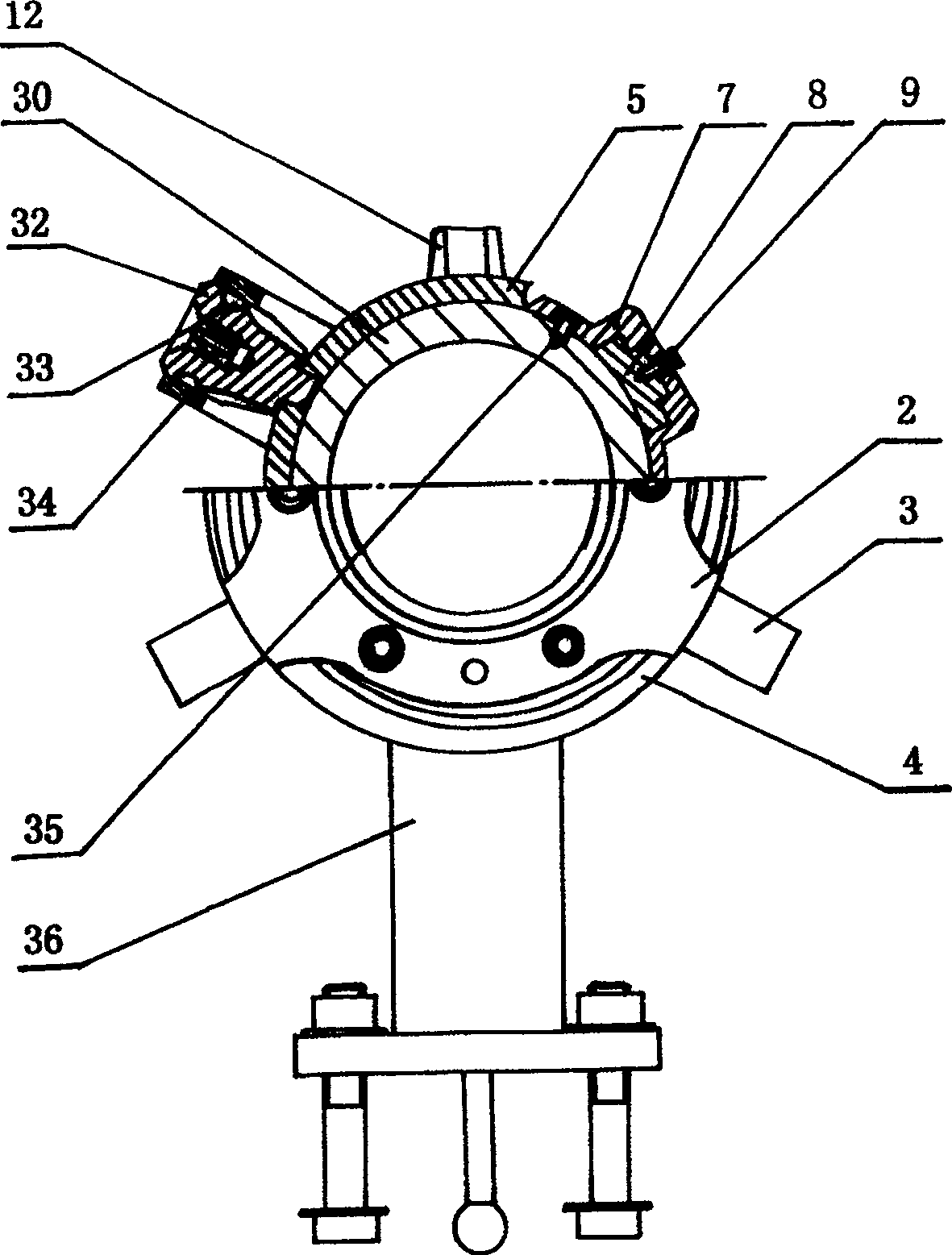

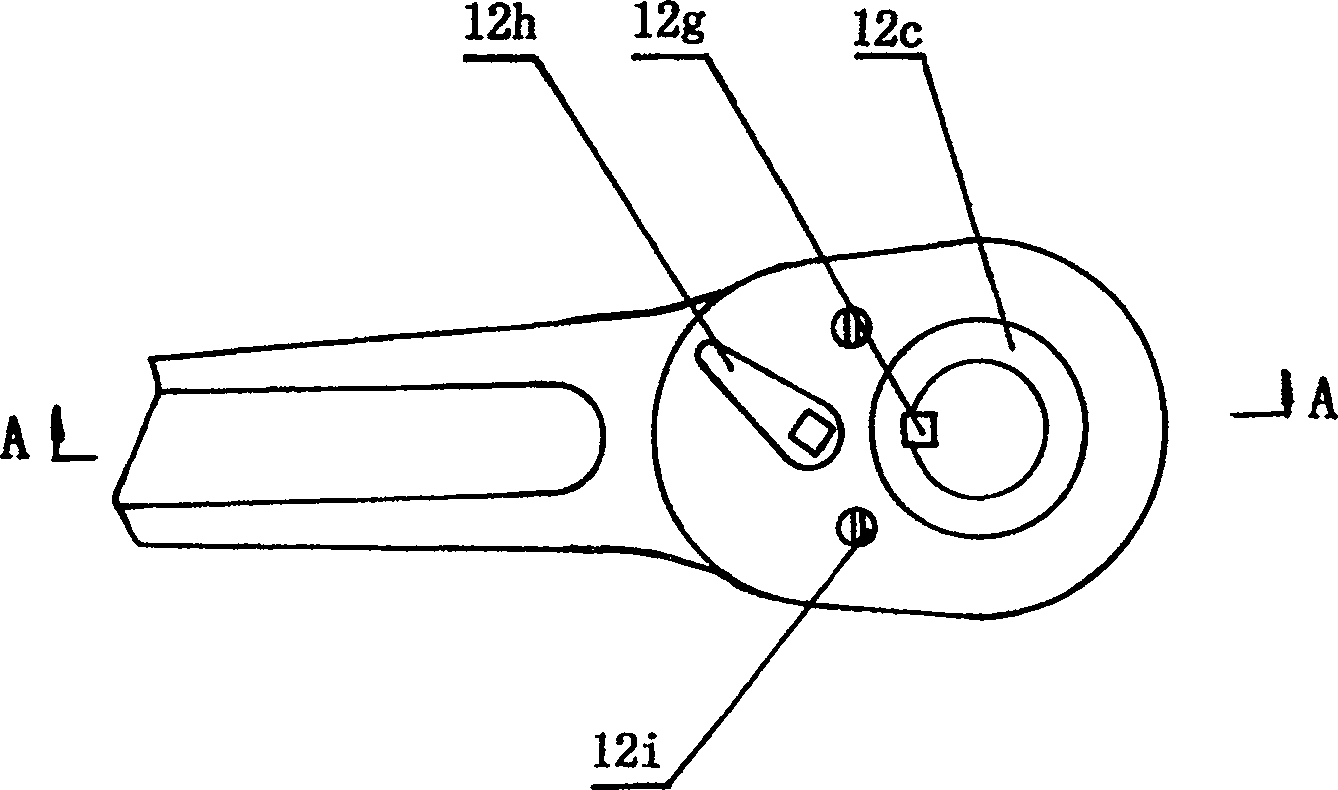

[0014] Refer to attached figure 1 , 2 , this portable fuze decomposing machine that the embodiment of the present invention provides, has fuze clamping device, the three-jaw chuck 27 that clamps fuze detonator tube to use, drives the three-jaw chuck that clamps fuze detonator tube to rotate and front and back The moving operating mechanism is also equipped with a Yu-style detonator wrench 29, and the fuze clamping device is composed of a chuck body 30 with three radial chutes evenly distributed on the disk surface and a tailpiece 28, and three pieces of the chuck body 30 are sub-packaged. The claws 3 in the radial chute, the disc surface set on the chuck body 30 are formed with equi-pitched helical teeth and the disc wire 4 with umbrella-shaped teeth and its positioning ring 5 are formed on the disc back, and the bracket 34 The driving bevel gear 32 with crank handle slot installed on the outer edge of the chuck body 30 is composed of the claws 3 installed in the three radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com