Labor-saving time-saving torque amplifier

A technology of torque booster and planetary gear, applied in gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of increasing torque of torque booster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

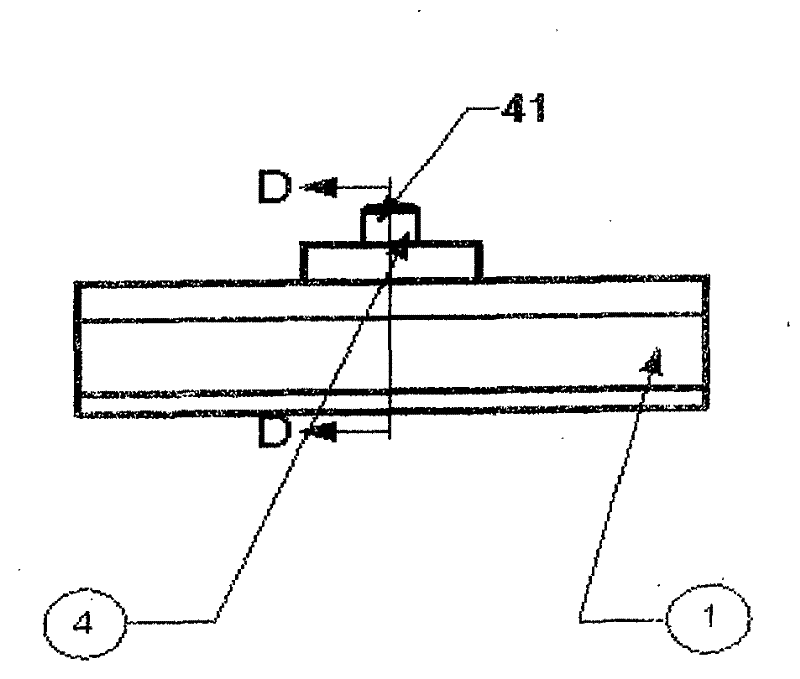

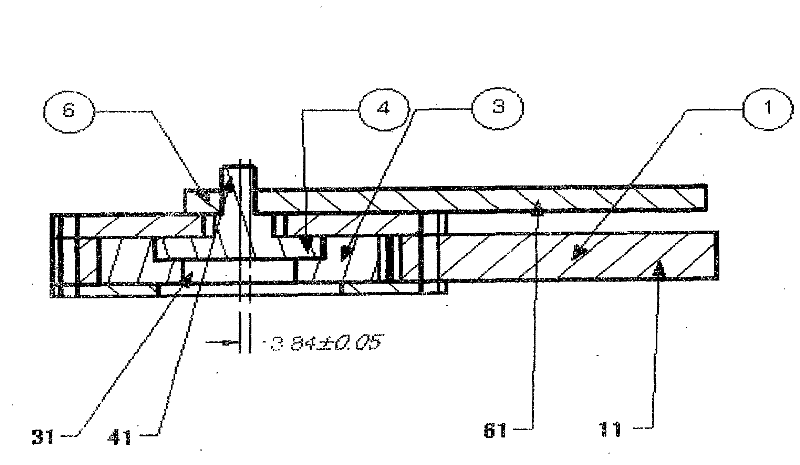

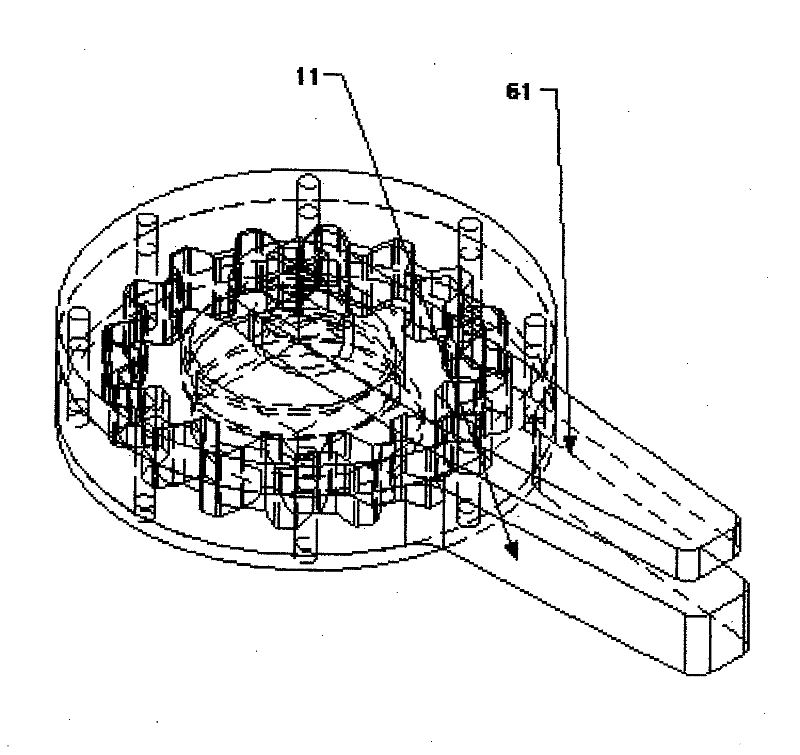

[0011] refer to figure 1 and figure 2 The torque booster during the labor-saving festival is composed of three components such as an internal gear ①, a planetary gear ③ and an eccentric shaft ④ in a small-tooth differential transmission. The internal gear ① is provided with a wrench 11; the planetary gear ③ is provided with an output square hole 31; the end of the eccentric shaft ④ is provided with a square head 41; rotate. Internal gear ① and planetary gear ③ adopt a gear pair with less tooth difference transmission. The transmission ratio of the gear pair is the same as the multiple required to increase the torque. Because this torque booster is provided with two wrenches 11 and 61, when the two wrenches 11 and 61 rotate together as a whole, the torque applied to the occasion that needs to be twisted is small, and the twisting time is faster; when one wrench 11 Fixed, when the other wrench 61 rotates, the torque applied to the occasion that needs to be twisted is very l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com