Vehicle bridge with vibrational and structure-borne noise damping

A solid-state sound and bridge technology, applied in bridges, bridge parts, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

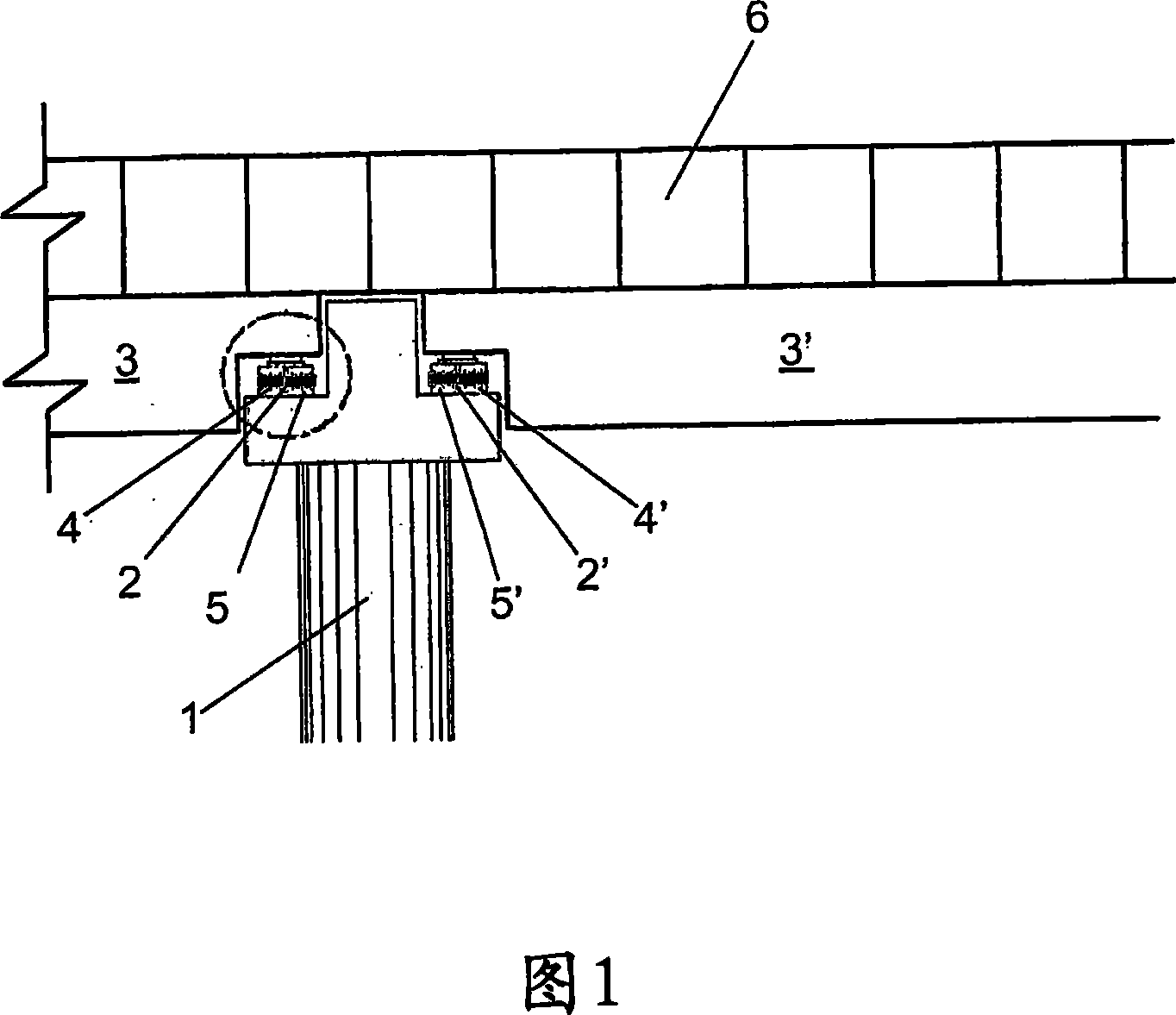

[0013] FIG. 1 shows a schematic view of a part of a vehicle bridge according to the invention, including its basic elements. The figure shows a bridge pier 1 on which parts of the support device 3 , 3 ′ are supported. The bridge pier 1 itself is supported on a substructure, not shown here, and the components of the bearing devices 3 , 3 ′ shown in the figures are supported on the bridge pier 1 in a known manner via bridge supports 2 , 2 ′. Arranged above the support devices 3 , 3 ′ is a superstructure 6 for the roadway, which is, for example, a track arrangement of the road, which is delimited on both sides by railings or barriers.

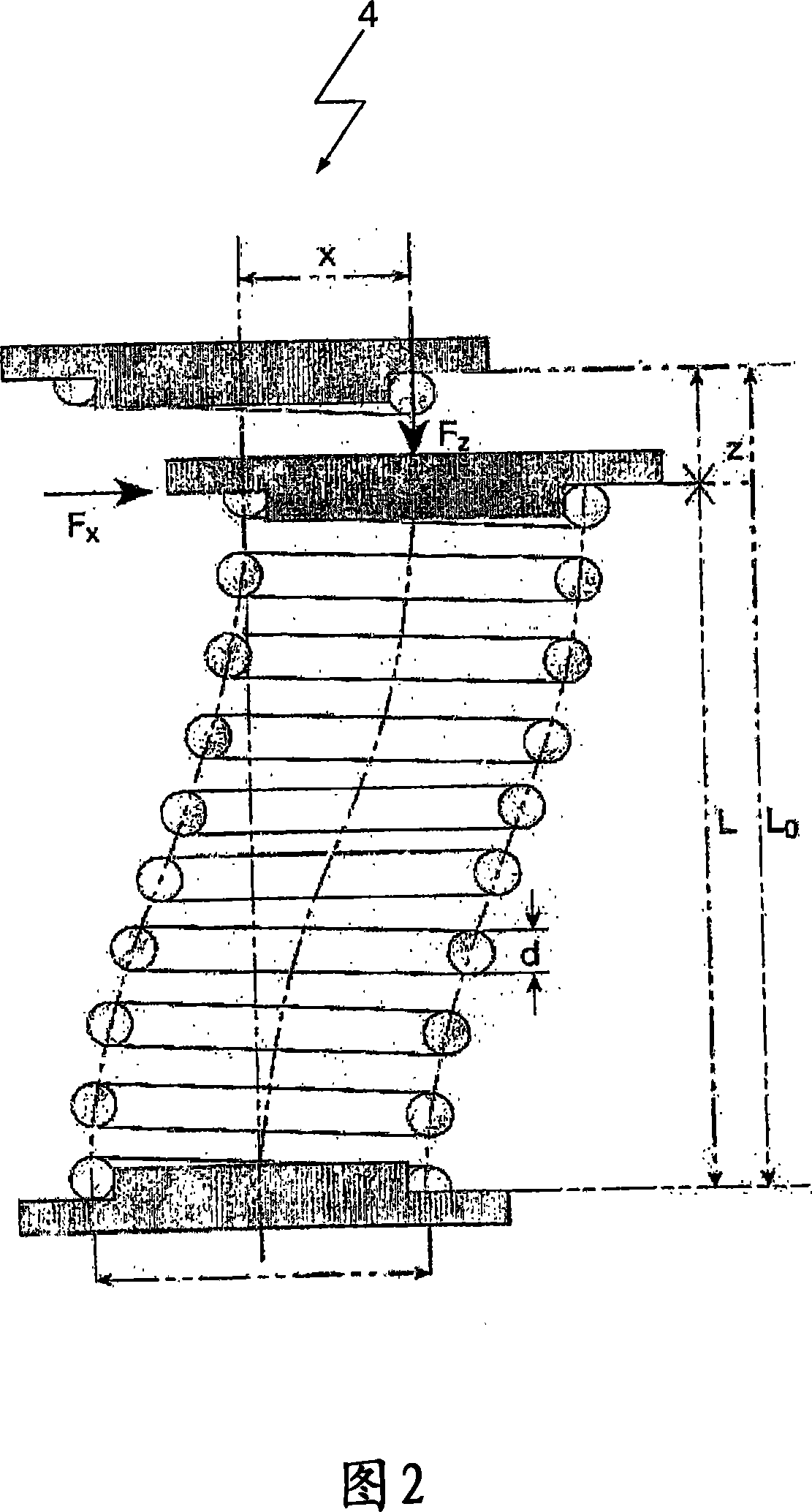

[0014] As is known, the bridge bearings 2 , 2 ′ have a horizontal elasticity through which the horizontal movement of the bridge pavement or the support device 3 , 3 ′ takes place, said horizontal movement occurring in particular due to temperature changes. However, unlike what is known from the prior art, no elastomeric bearings are involved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com