Rail traveling type beam moving stillage truck

A rail-type, horizontally moving trolley technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor synchronization and safety, inconvenient operation, and high labor intensity, and achieve low pipeline requirements , low labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described as follows with reference to accompanying drawing in conjunction with specific embodiment:

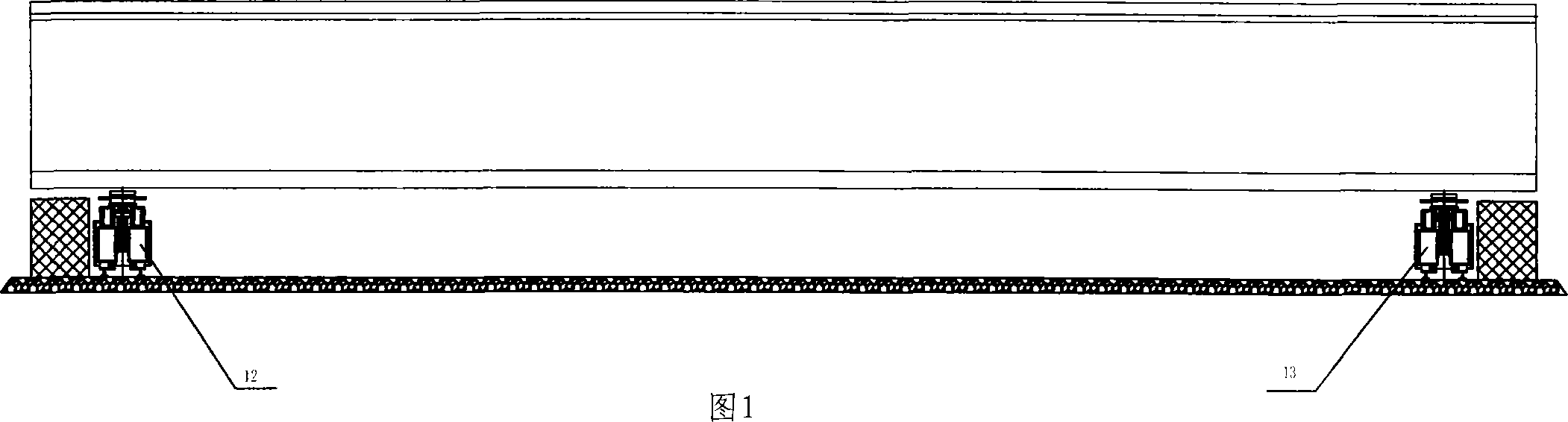

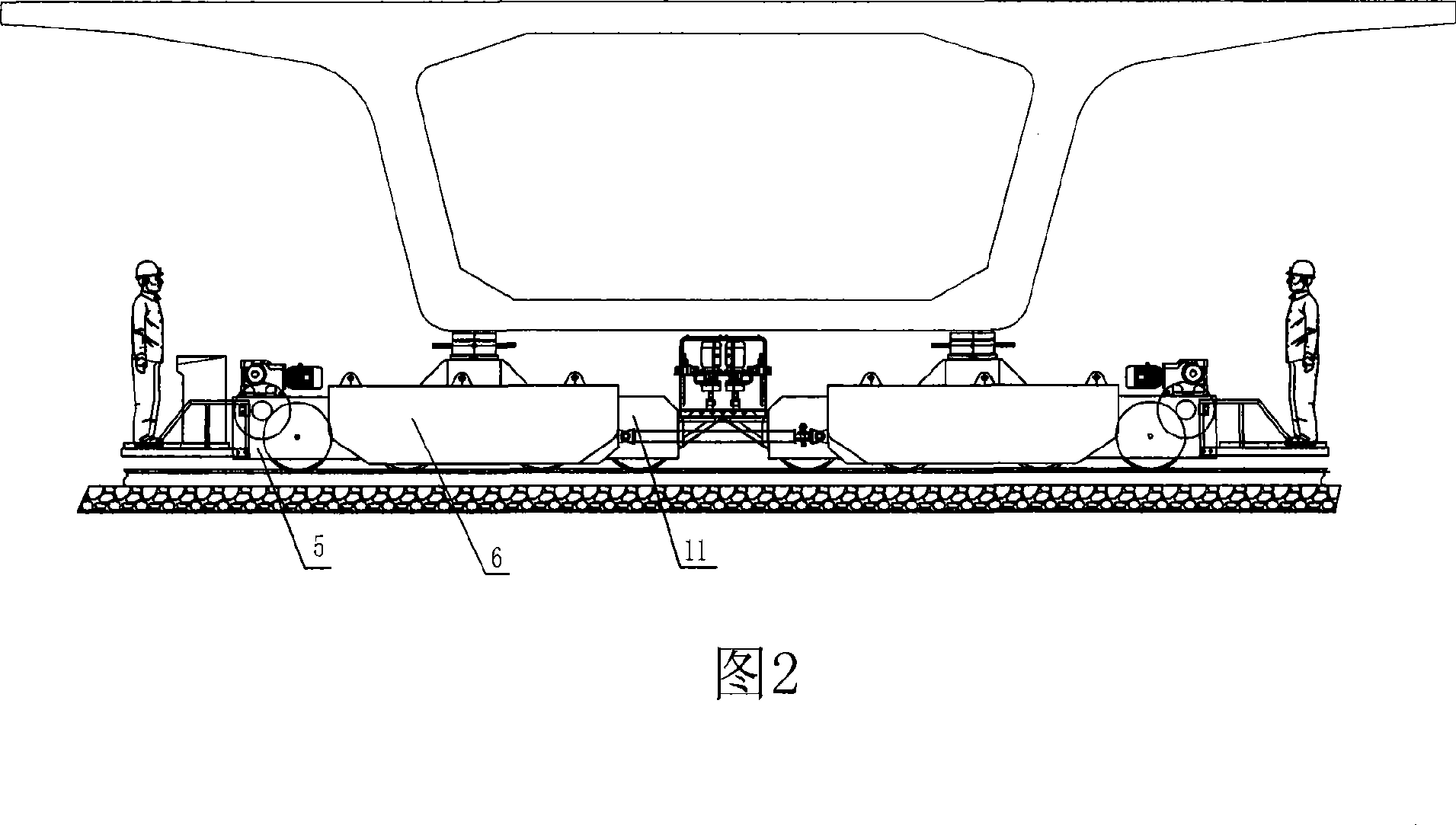

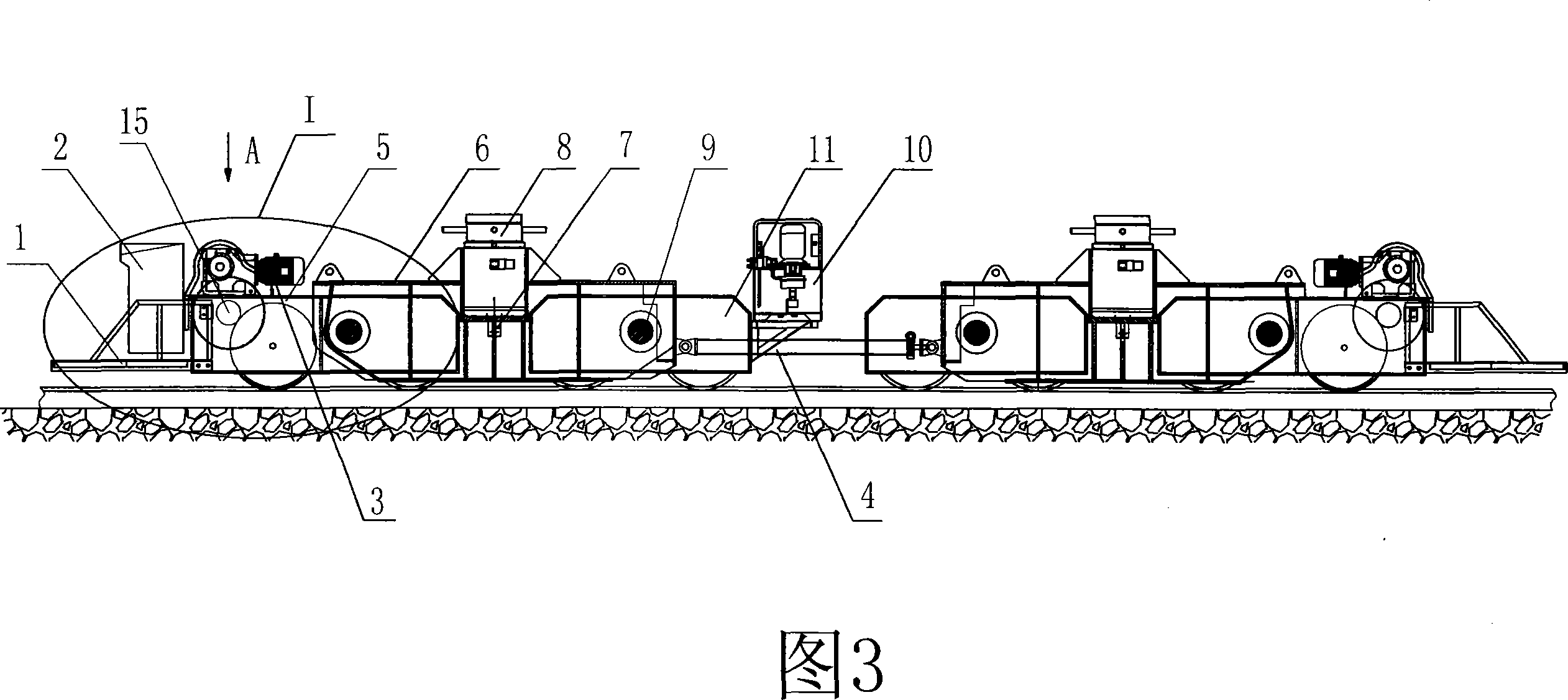

[0021] Referring to Fig. 1, 2, 3, 4, the main traversing trolley 12 and the auxiliary traversing trolley 13, the main traversing trolley 12 and the auxiliary traversing trolley 13 are respectively composed of two traveling flat cars, and the two walking parallel The car is rigidly hinged through the balance connecting rod 4, and each flat car includes two active trolleys 5 and two passive trolleys 11, the active trolley and the passive trolley are connected by a balance beam 6, and the jacking cylinder 8 is installed on the side of the flat trolley. On the balance beam 6, a reducer 3 is provided at one end of the balance beam 6, a hydraulic pump station 10 is provided at the other end, and a balance main shaft 9 is provided below, and a pressure pump electrically connected to the PLC control system is installed on the jacking cylinder 8. And th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com