Figured plate rolling arrangement roller mode and its figured plate rolling method

A patterned roll and patterned plate technology, which is applied in the direction of rolling force/roll gap control, roll, metal rolling, etc., can solve problems such as unstable quality, roll peeling, and large limitations, so as to achieve easy mastery and avoid roll peeling , easy to select the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

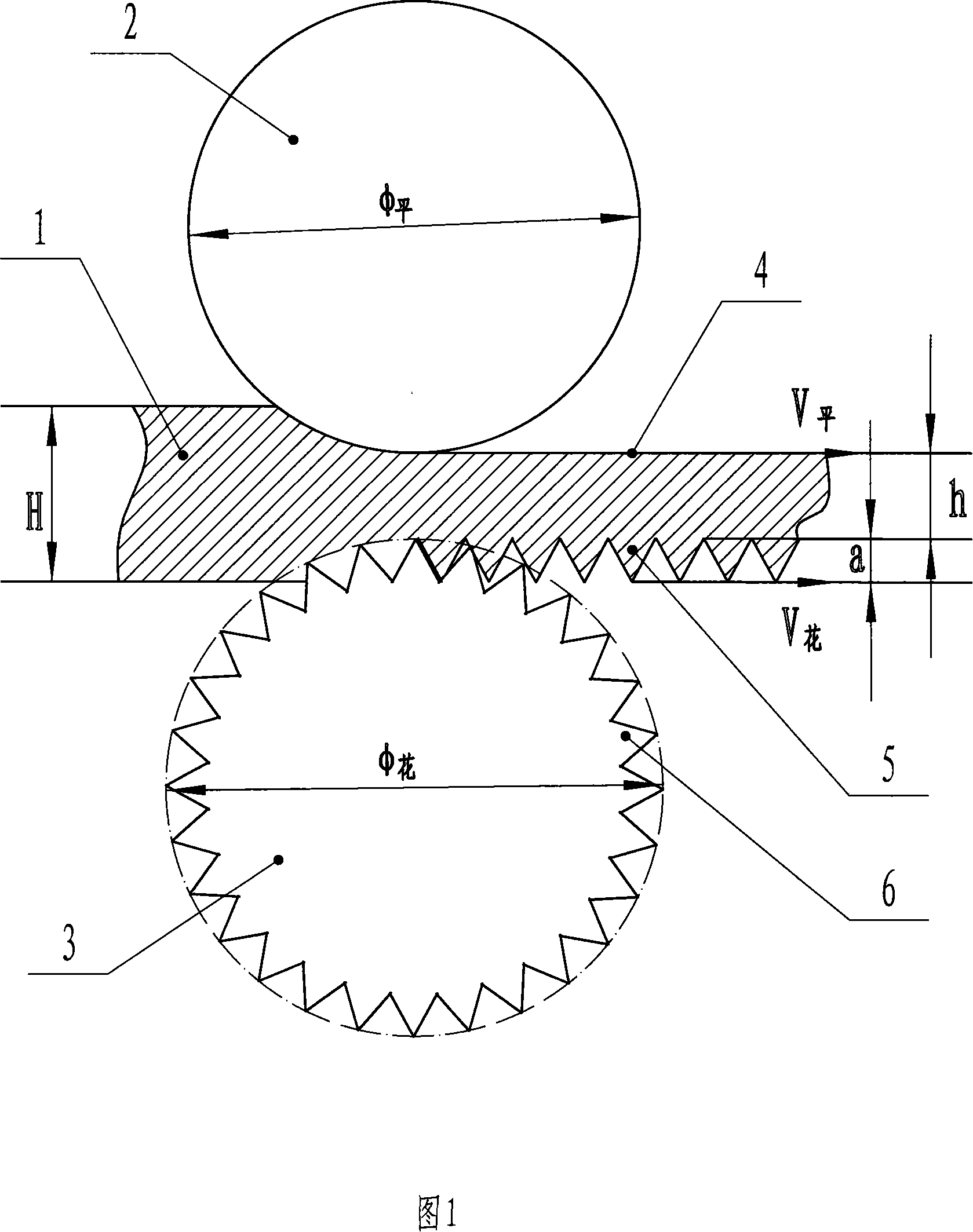

[0036] In this embodiment, the pattern plate 4 made of Q235A is rolled, the thickness h of the substrate is 1.5 mm, the bean height a of the pattern 5 is 0.3 mm, and the diameter of the flat roll 2 is Φ 平 is 600mm, the front slip value f of the flat roller 平 is 0.5mm, the diameter of pattern roller 3 is

[0037] Φ 花 = Φ 平 +2×a+f 平 =600+2×0.3+0.5=601.1mm

[0038] What this embodiment adopts is hot continuous rolling mill rolling, adopts above-mentioned flat roll and pattern roll, and pattern roll is arranged under the flat roll, pattern plate rolling pressure is 1100t, rolling mill motor power 4500KW. The checkered plate rolling method step of the present embodiment is as follows:

[0039] (1) Heating continuous casting slab

[0040] The thickness of the slab is 210mm, the heating temperature is 1250°C, and the dwelling time is 180 minutes;

[0041] (2) Rough rolling

[0042] Exit thickness is 35mm, descaling is four steps, rough rolling exit temperature is 1140℃

[00...

Embodiment 2

[0048] In this embodiment, the patterned plate 4 whose material is Q195A is rolled, the thickness h of the substrate is 2.35 mm, the bean height a of the pattern 5 is 0.5 mm, and the diameter of the flat roll 2 is Φ 平 is 600mm, the front slip value f of the flat roller 平 is 0.5mm, the diameter of pattern roller 3 is

[0049] Φ 花 =600+2×0.5+0.5=601.5mm

[0050] What this embodiment adopts is hot continuous rolling mill rolling, the patterned roller is arranged under the flat roller, the rolling pressure of the patterned plate is 1100t, and the motor power of the rolling mill is 4500KW; The drop rate is 11%, the finish rolling temperature is 880°C, and the groove depth of the new patterned roll is 4mm.

Embodiment 3

[0052] What is rolled in this embodiment is the checkered plate 4 whose material is Q215A, the thickness h of the base plate is 2.75mm, the bean height a of the checkered pattern 5 is 0.6mm, and the diameter of the flat roll 2 is Φ 平 is 600mm, the front slip value f of the flat roller 平 is 0.5mm, the diameter of pattern roller 3 is

[0053] Φ 花 =600+2×0.6+0.5=601.7mm

[0054] What this embodiment adopts is hot continuous rolling mill rolling, the patterned roller is arranged under the flat roller, the rolling pressure of the patterned plate is 1100t, and the motor power of the rolling mill is 4500KW; The down rate is 13%, the final rolling temperature is 880°C, and the groove depth of the new patterned roll is 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com