Multi-layer sleeve structure

A sleeve and outer cylinder technology, applied in the field of multi-layer sleeve structure, can solve problems such as poor bonding, easy slipping and separation, and achieve the effects of improving market competitiveness, good structural strength, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

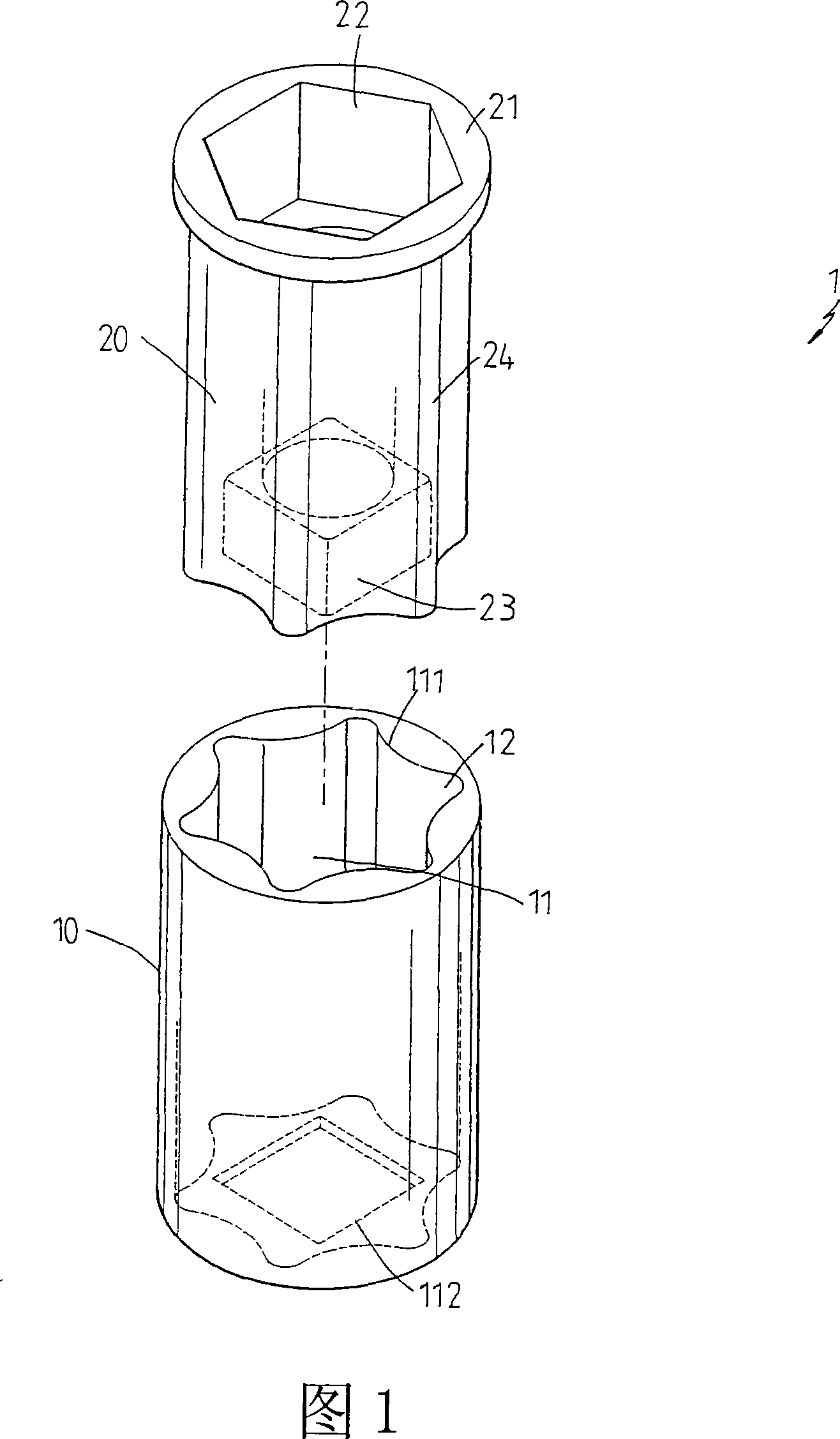

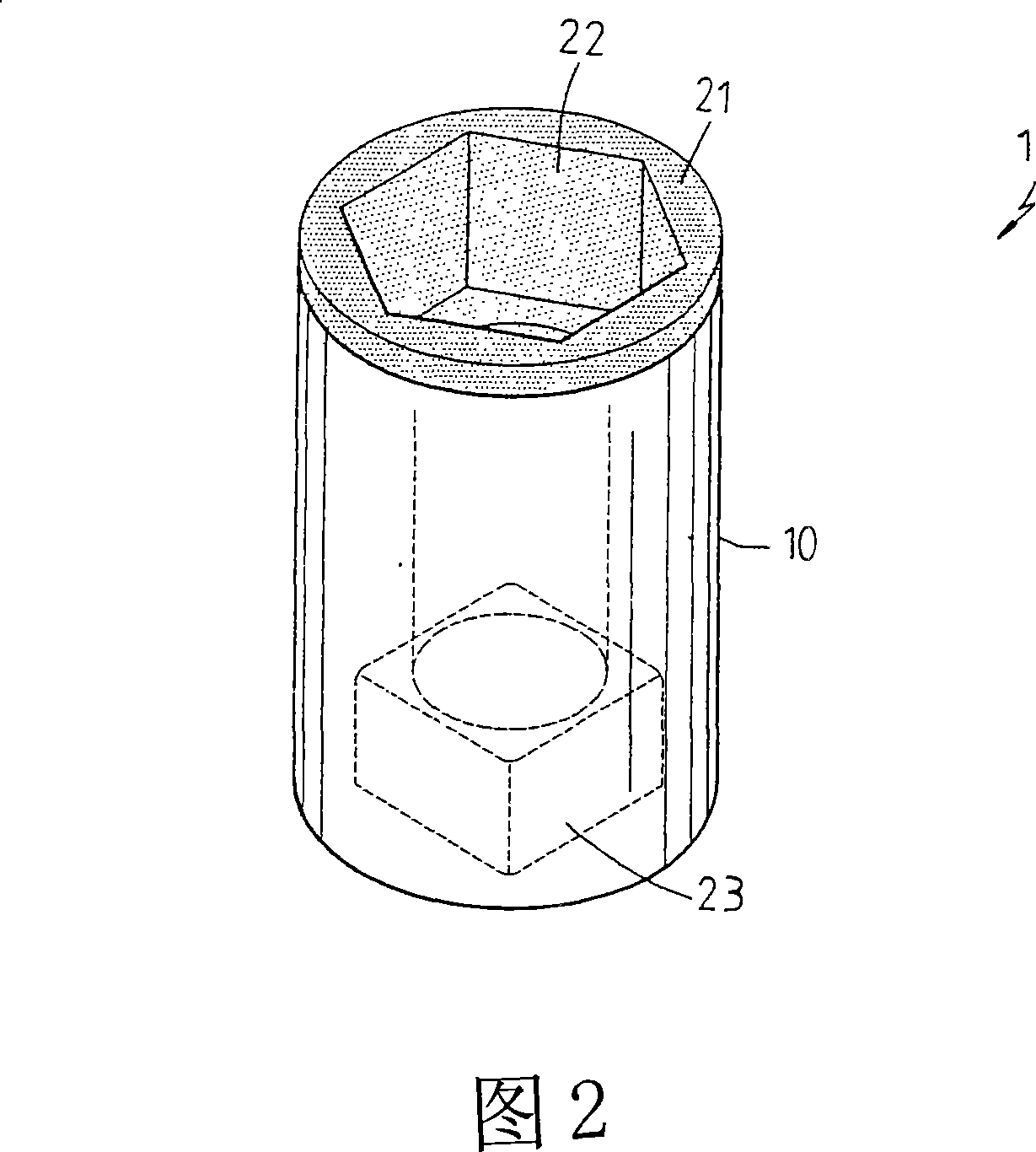

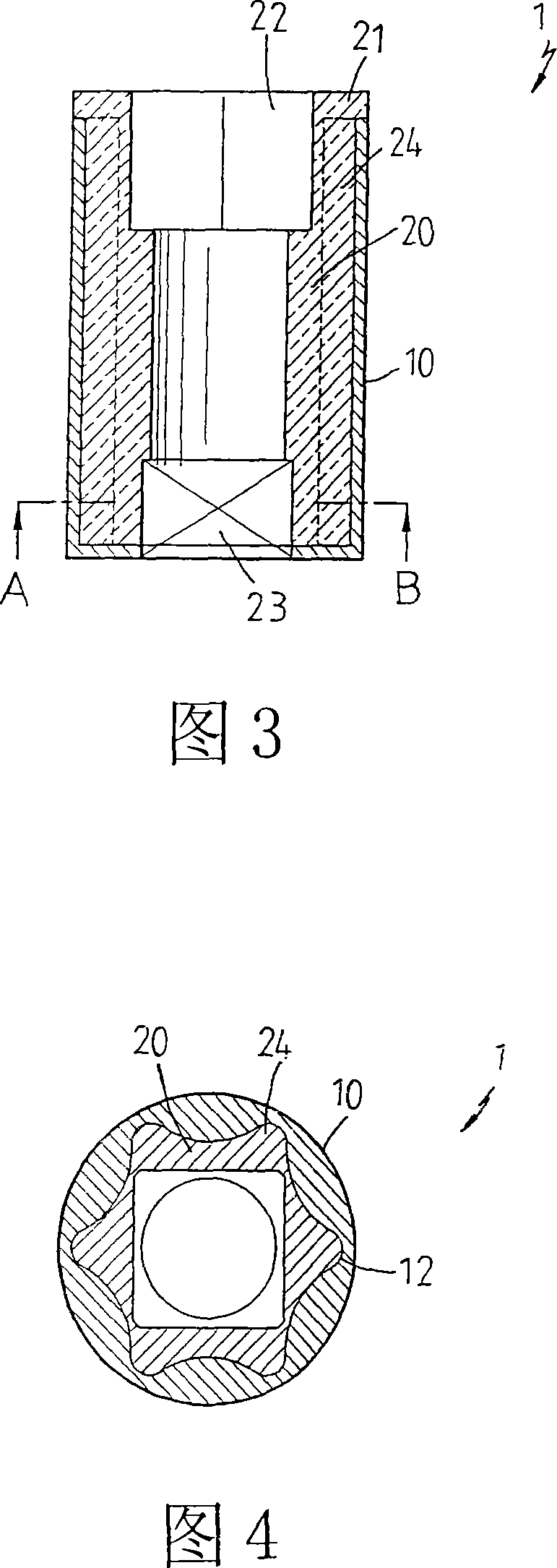

[0050] A kind of multi-layer sleeve structure of the present invention, please refer to Fig. 1 to shown in Fig. 5, this sleeve 1 mainly comprises an outer cylinder 10 and an inner bushing 20, and this outer cylinder 10 is made of hard steel, and the inner lining The sleeve 20 is made of aluminum material with poor hardness, and an anti-slip device composed of corresponding grooves 12 and flanges 24 is provided between the outer cylinder 10 and the inner sleeve 20;

[0051] The outer cylinder 10 is generally in the shape of a hollow cylinder, and has an accommodating space 11 inside for the inner liner 20 to accommodate. The periphery of the space 11 is provided with several grooves 12. In this embodiment, the grooves 12 are arc-shaped and arranged around the periphery of the accommodating space 11;

[0052] The inner liner 20 is generally cylindrical, with a convex buffer section 21 on the outer side of the top end, and a pulling port 22 on the inner side of the top end, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com