Yarn cutting and retaining device, and flat knitting machine

A technology for cutting device and knitting yarn, which is applied to flat knitting machines, knitting, and weft knitting with individual moving needles, which can solve the problem of increased installation space and achieve the effect of keeping the cutting device compact and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

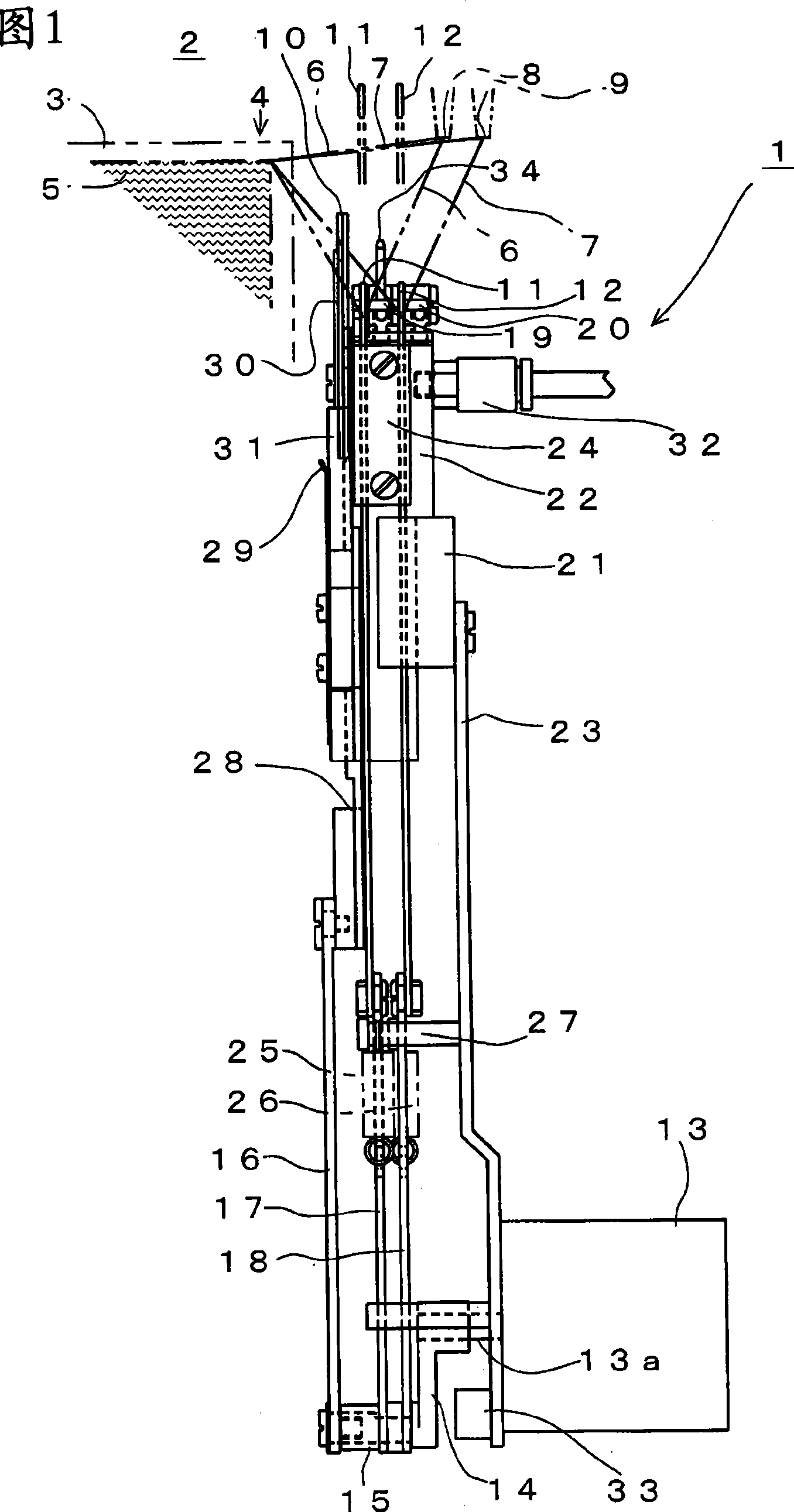

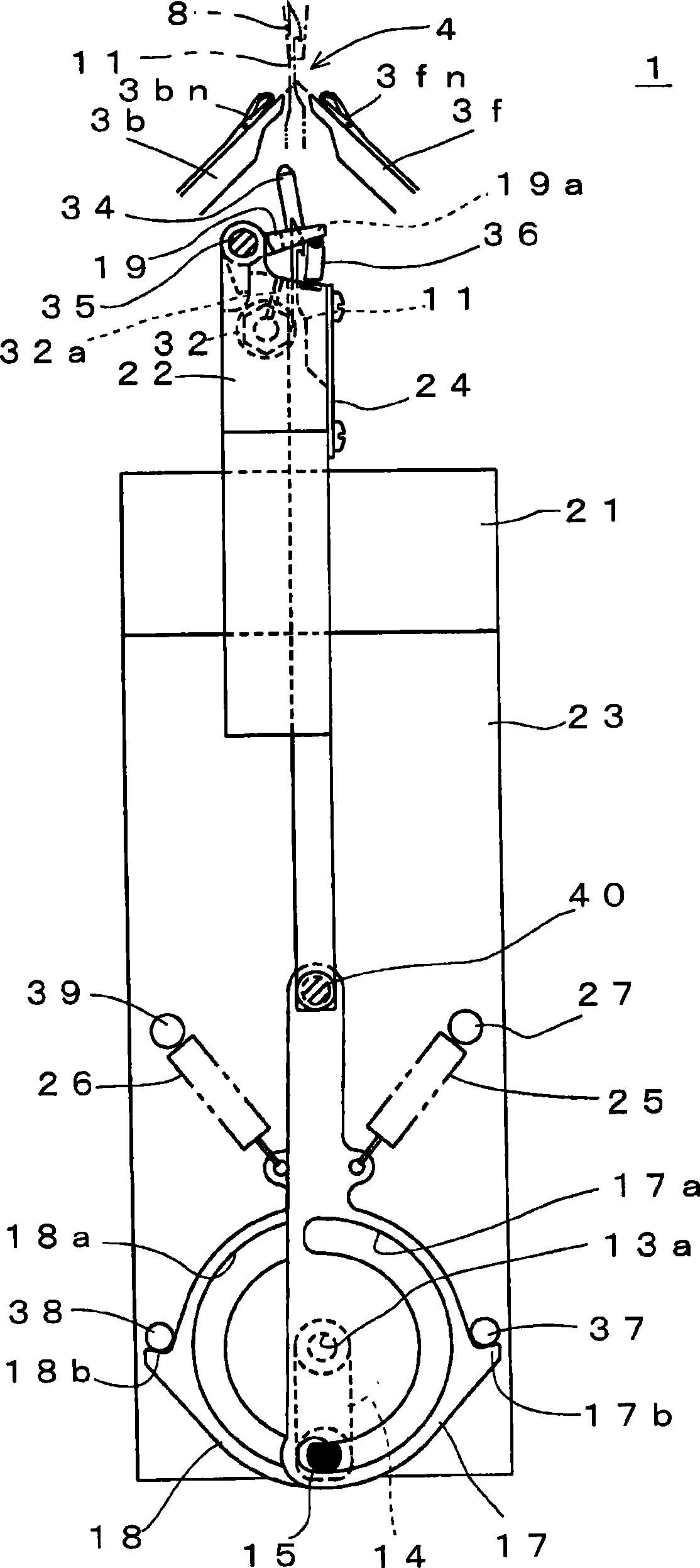

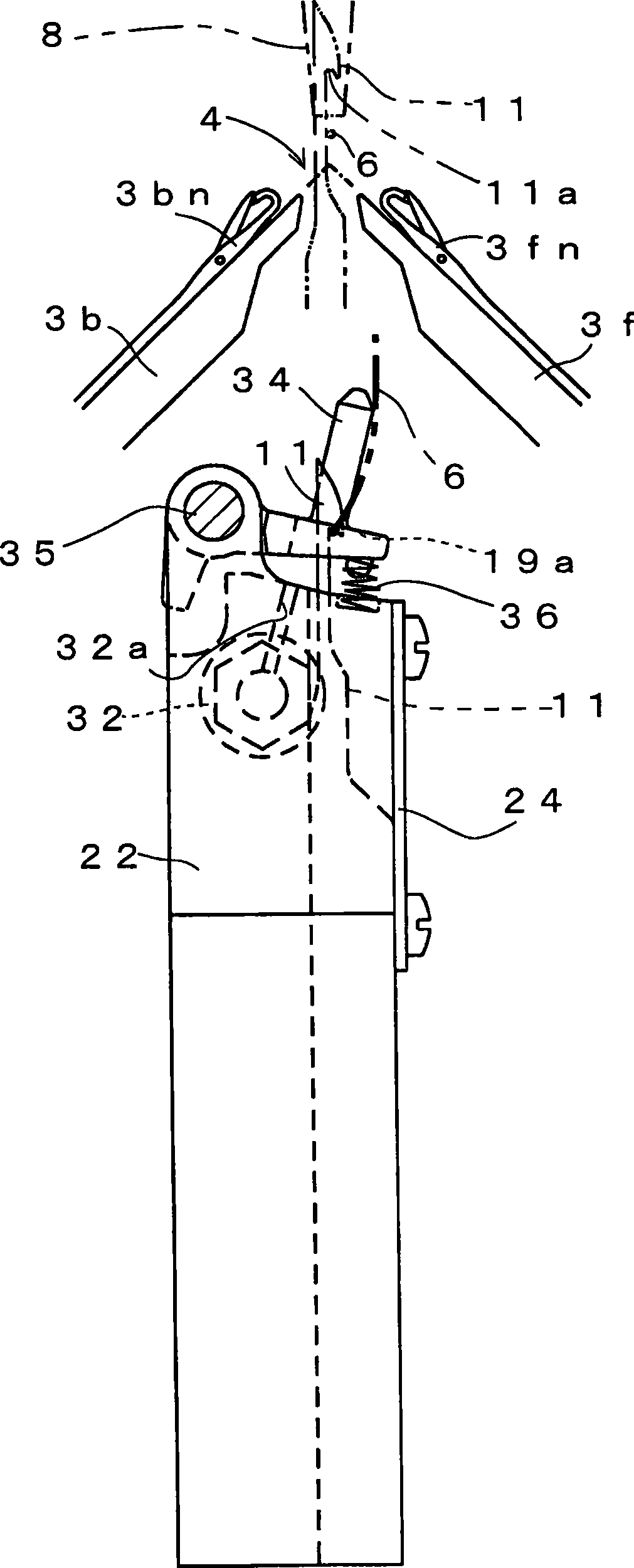

[0063] Figure 1 to Figure 12 A schematic configuration of a knitting yarn holding and cutting device 1 according to an embodiment of the present invention is shown. In addition, in the following description, the part corresponding to the part demonstrated above is attached|subjected with the same reference symbol, and a redundant description is abbreviate|omitted.

[0064] figure 1 A partial configuration of the flatbed knitting machine 2 provided with the knitting yarn holding and cutting device 1 of the present embodiment is briefly shown. The knitting yarn holding and cutting device 1 is provided below the needle bed 4 where the front and rear needle beds 3 face each other or below the side ends of the needle bed 4 in the flatbed knitting machine 2 having the front and rear needle beds 3 . In the flatbed knitting machine 2 , the knitted fabric 5 can be knitted individually by each needle bed 3 , or can be knit in a cylindrical shape while knitting both ends of the knitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com