Heat pipe with compound capillary structure and manufacturing method thereof

A capillary structure and heat pipe technology, applied in the field of heat pipes, can solve the problems of high manufacturing cost, lack of capillary structure, and inability to fully exert heat transfer efficiency, and achieve the effect of fast production rate and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

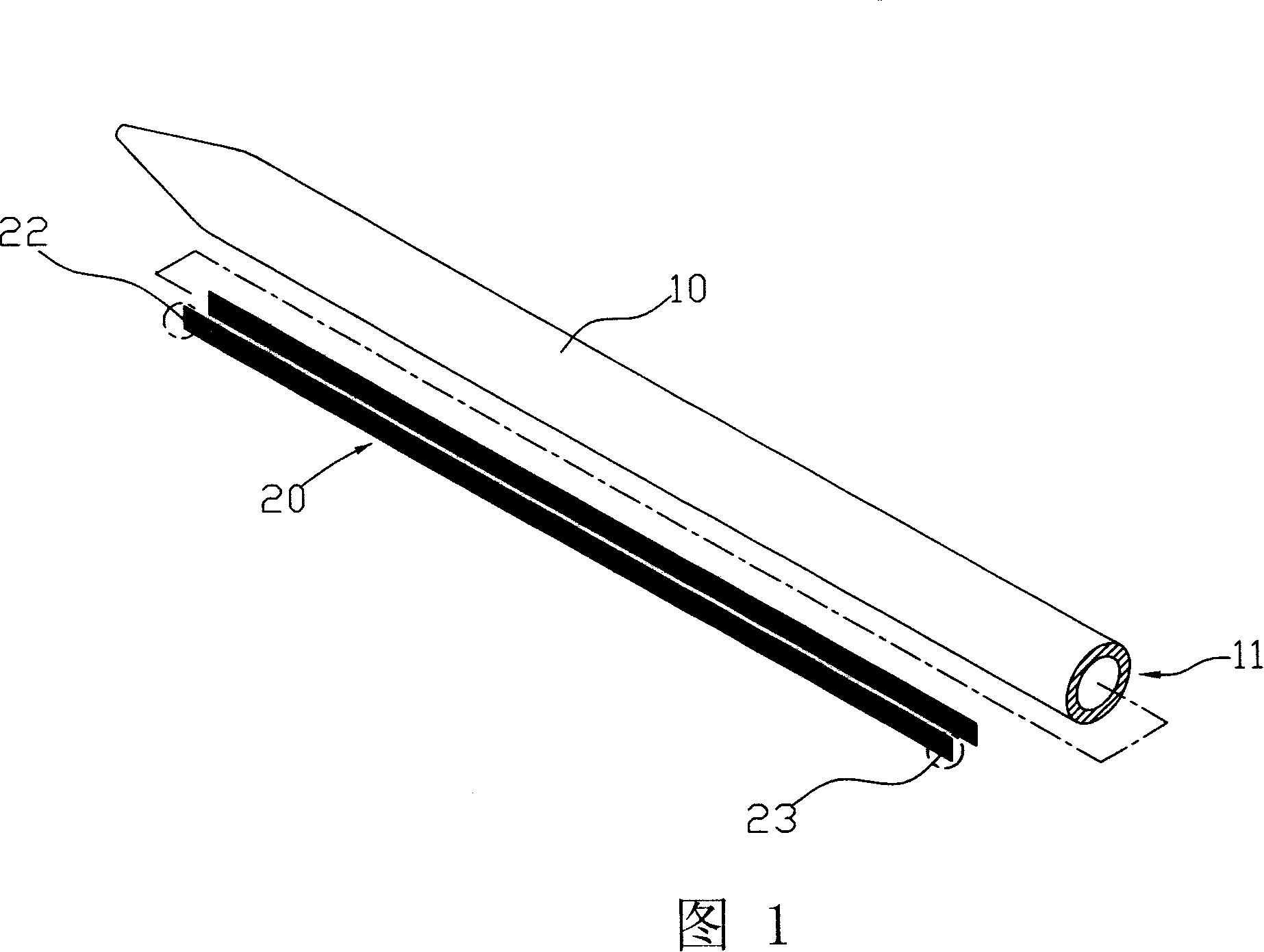

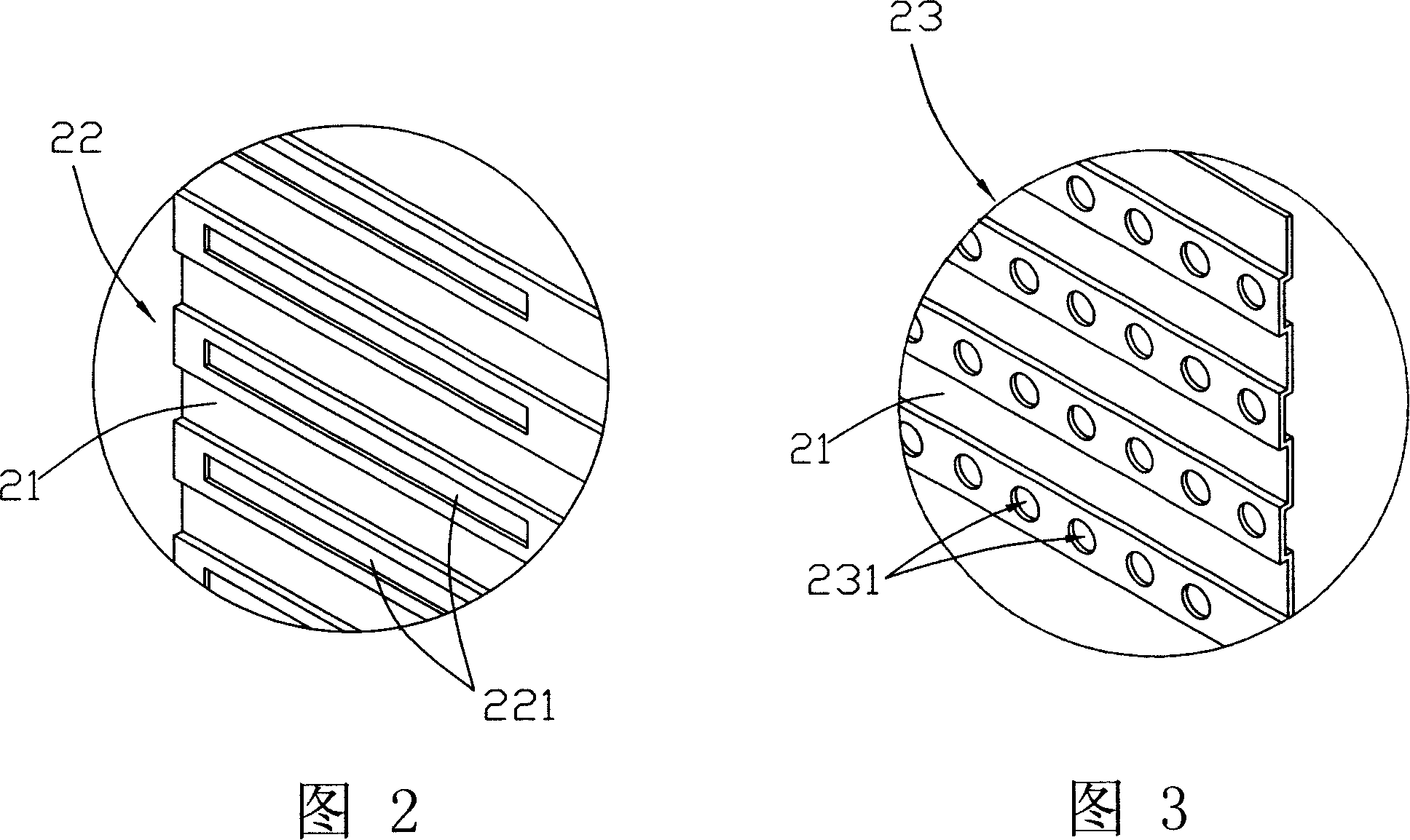

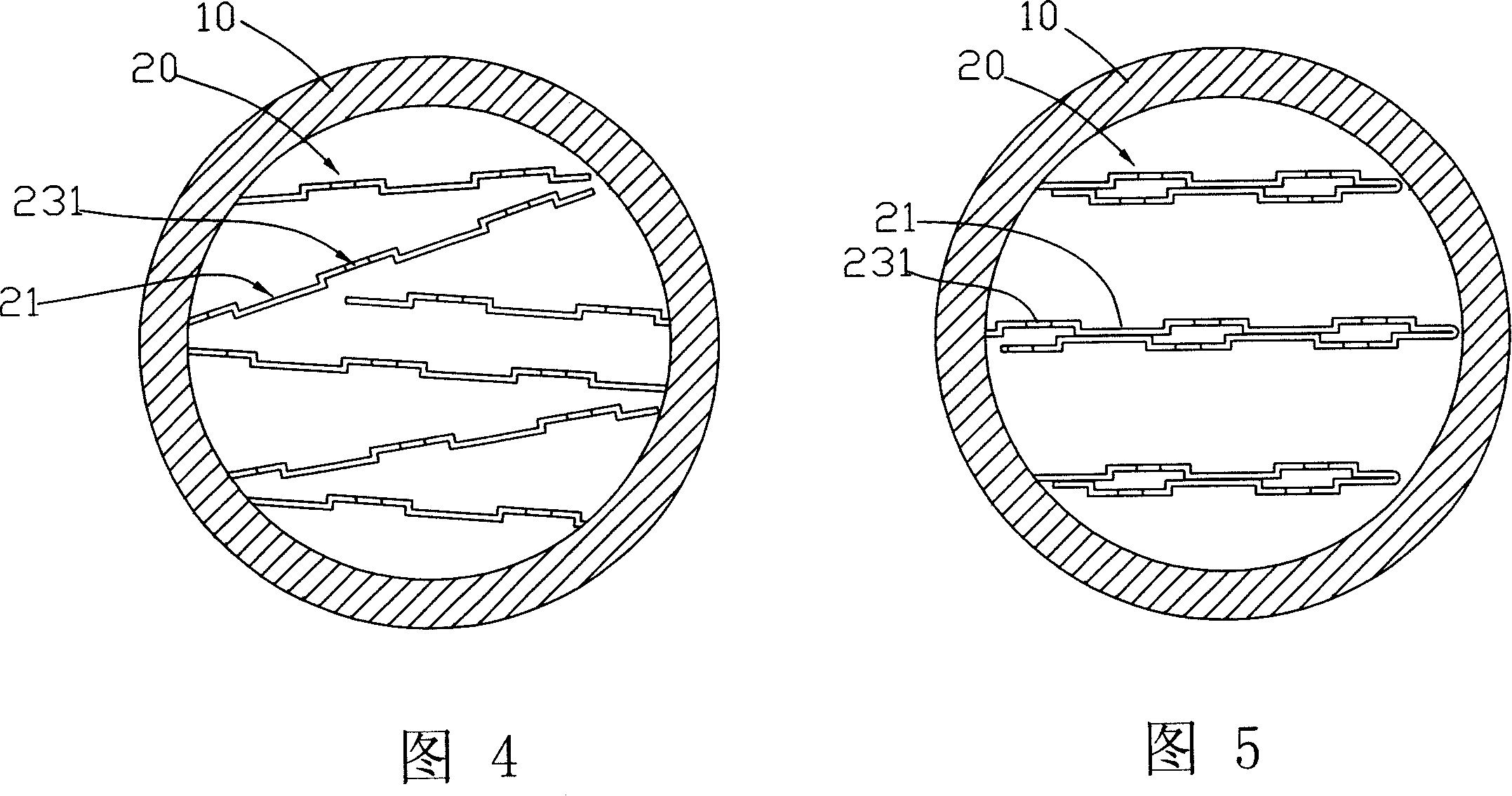

[0021] First please refer to Fig. 1, Fig. 2 and Fig. 3, which is a heat pipe with a composite capillary structure provided by the first embodiment of the present invention, including a hollow shell tube 10, at least one metal sheet 20 and a filling in the middle The working fluid in the hollow tube 10 (not shown in the figure).

[0022] The hollow shell tube 10 is a material with good thermal conductivity, and it is made into a predetermined length and bent shape according to the requirements. It has at least one open end 11, and the open end 11 can be used for the metal sheet 20 and the working fluid to be inserted into the hollow The shell tube 10 is closed after the heat pipe is fabricated.

[0023] The shape of the metal sheet 20 is to match the shape of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com