Voltage buffer and its source electrode driver

A technology of voltage buffer and current source, which is applied in the direction of instruments and static indicators, etc., can solve the problems of liquid crystal display display quality degradation, high load capacitance at the panel end, low slew rate of voltage buffer 100, etc., to improve the display picture Quality, improve the effect of turning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

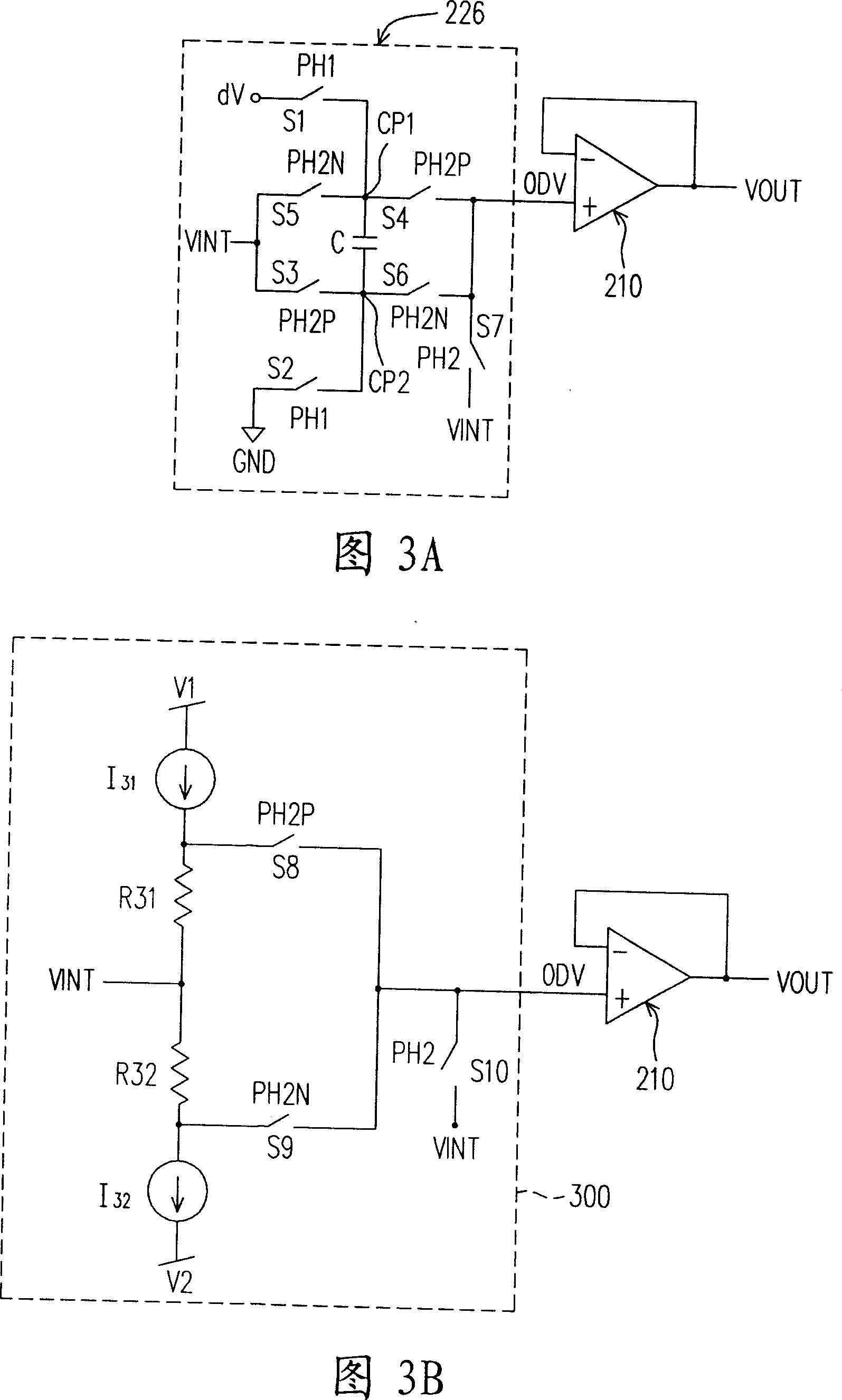

[0096] FIG. 2 is a circuit block diagram of a voltage buffer according to an embodiment of the invention. The voltage buffer 200 includes an operational amplifier 210 and an overdrive unit 220 . The operational amplifier 210 has a positive input terminal, a negative input terminal and an output terminal, and the output terminal is coupled to the negative input terminal to form a negative feedback structure. The voltage output by the output terminal is an output voltage VOUT. The overdrive unit 220 is coupled between an input voltage VINT and the operational amplifier 210 for comparing the input voltage VINT and the output voltage VOUT, and outputting an overdrive voltage ODV to the positive input terminal of the operational amplifier 210 .

[0097] Wherein, according to the comparison result of the overdrive unit 220, if the input voltage VINT is greater than the output voltage VOUT, then the overdrive voltage ODV is greater than the input voltage VINT; if the input voltage V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com