Safety grating

A safety barrier and intrinsically safe technology, applied in the field of safety barriers, can solve the problems of small output intrinsically safe current, inability to automatically start and self-recover, small load inductance and capacitance, etc., to achieve large load inductance, large load capacitance, The effect of high output power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

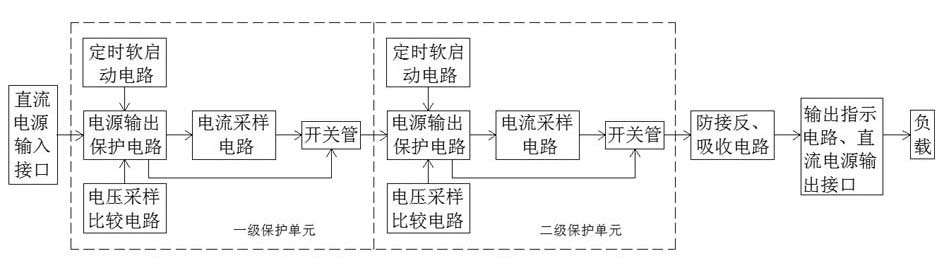

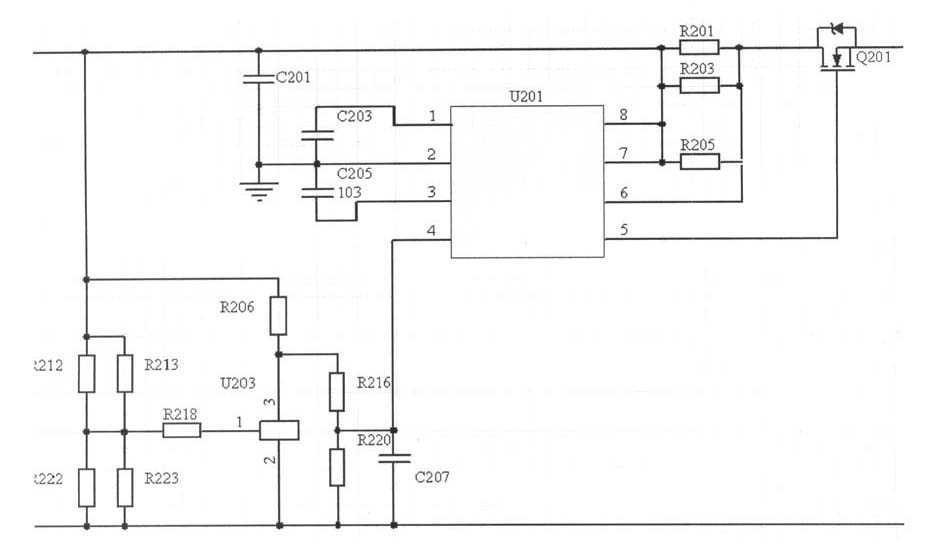

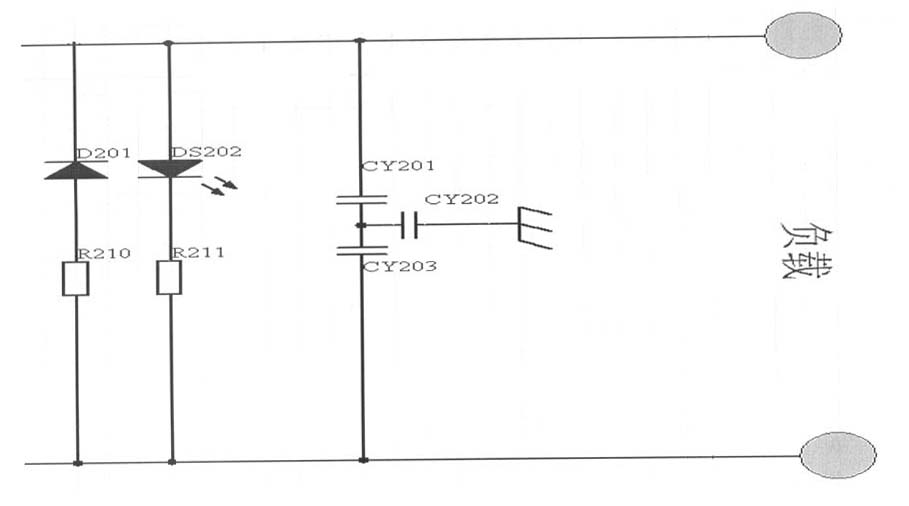

[0010] Such as figure 1 As shown, the safety barrier of the present invention includes a protection circuit arranged in the casing and an intrinsically safe DC power input and output interface arranged on the casing wall; the protection circuit consists of a two-stage power supply protection unit, an input terminal and the output end of the second-level power protection unit are electrically connected to an anti-reverse and absorbing circuit; the input end of the first-level power protection unit is electrically connected to the input interface of the intrinsically safe DC power supply; the anti-reverse, The output end of the absorbing circuit is electrically connected to the intrinsically safe DC power supply output interface through the output indicating circuit; the two-stage power supply protection unit is composed of: power supply output protection circuit, current sampling circuit, timing soft start circuit, voltage sampling comparison circuit, The switch tube is formed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com