Flexible connection structure matched with electric heating flange of platinum channel

An electric heating method and platinum channel technology, applied in the direction of the feeding tank, etc., can solve the problems of insufficient thickness of the silver plating layer at the end, affect the current carrying capacity of the soft connection, and high cost of silver plating of copper wires, so as to achieve enhanced conductivity and increased heat dissipation capacity , the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

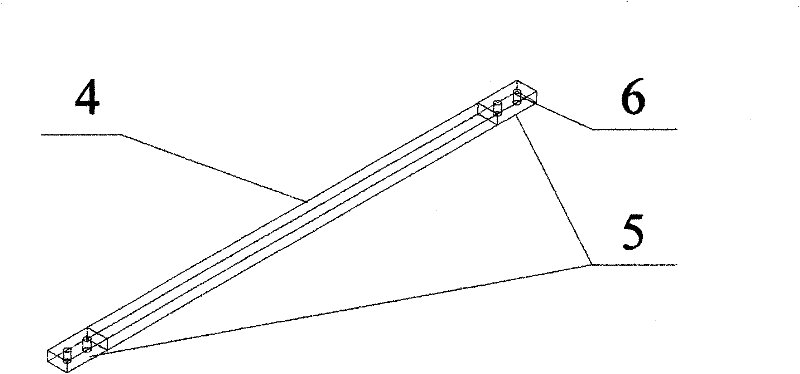

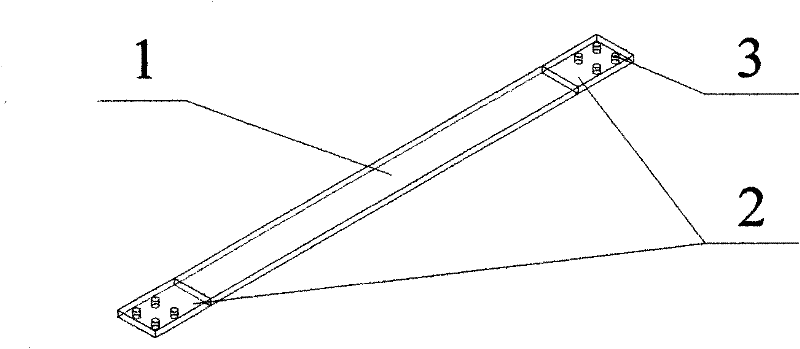

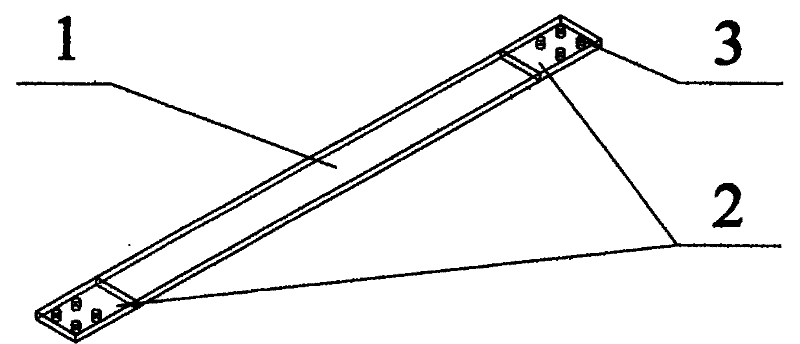

[0012] see figure 1 , a soft connection structure matched with the platinum channel electric heating flange. The above soft connection structure is positioned between the copper bar output by the transformer and the electric heating flange. The soft connection structure includes a conductive wire braided with an anti-corrosion layer, And the two ends of the conductive wire braided body are provided with conductive terminals with bolt connection holes. Under the condition that the cross-sectional area of the above-mentioned conductive wire braided body 1 is unchanged, the width and thickness ratio of the cross-section is set to 7:1 to 9:1.

[0013] The number of the bolt connection holes 3 on the two conductive ends 2 of the above-mentioned conductive wire braided body 1 is set to four respectively.

[0014] The material of the above-mentioned conductive wire braid 1 is copper wire.

[0015] The diameter of the above-mentioned copper wire is 0.12-0.15mm.

[0016] In order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com