AC motor over-load inverse time-lag protection method based on heat accumulation

A technology of inverse time protection and AC motors, applied in emergency protection circuit devices, electrical components, etc., can solve problems such as hard to find, low control accuracy, and inability to reflect motor thermal overload characteristics, and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

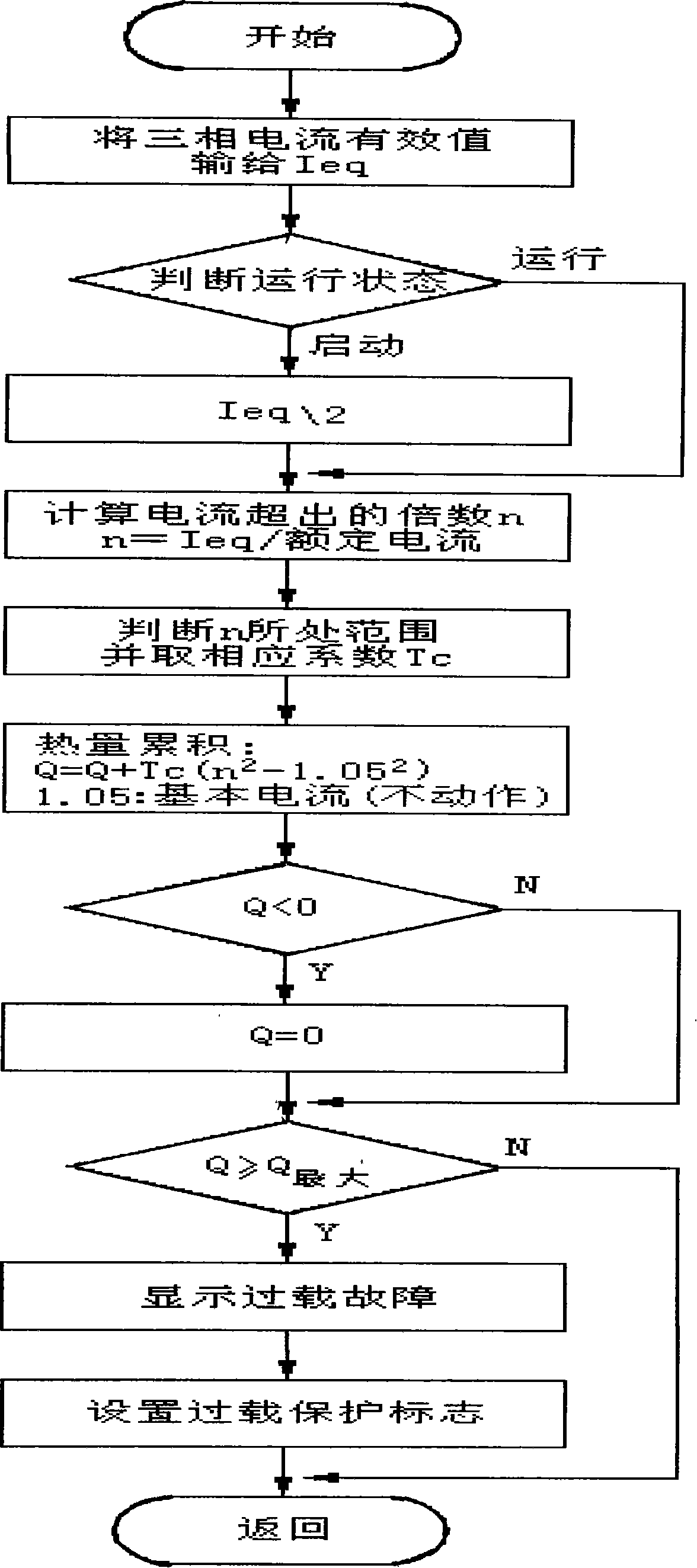

[0024] The AC motor overload inverse time protection method of the present invention, as shown in the accompanying drawing, is carried out according to the following steps:

[0025] (1) The overload protector of the AC motor collects the three-phase load current of the AC motor through AD conversion, and calculates the effective current I of each phase eq and load rate n,

[0026] Load rate n=I eq / I N , I N The rated operating current of the motor

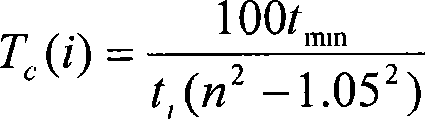

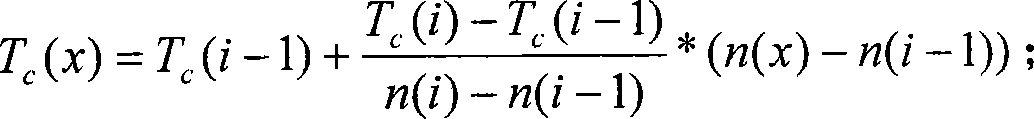

[0027] (2) According to the load rate n obtained in the previous step, calculate the heat accumulation coefficient T of each point corresponding to the load rate n c ,

[0028] a. Corresponding to the load rate n, the heat accumulation coefficient value Tc(i) of the motor at each ideal operating point is calculated according to the following formula (1). The ideal operating point refers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com