Sealed bearings multifunctional test machine and test methods thereof

A sealed bearing and multi-functional technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of large structural design problems of sealed bearings, poor sealing effect, unsatisfactory sealing performance of sealed bearings, etc., and achieve low cost, high test accuracy and Good stability, easy to use and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

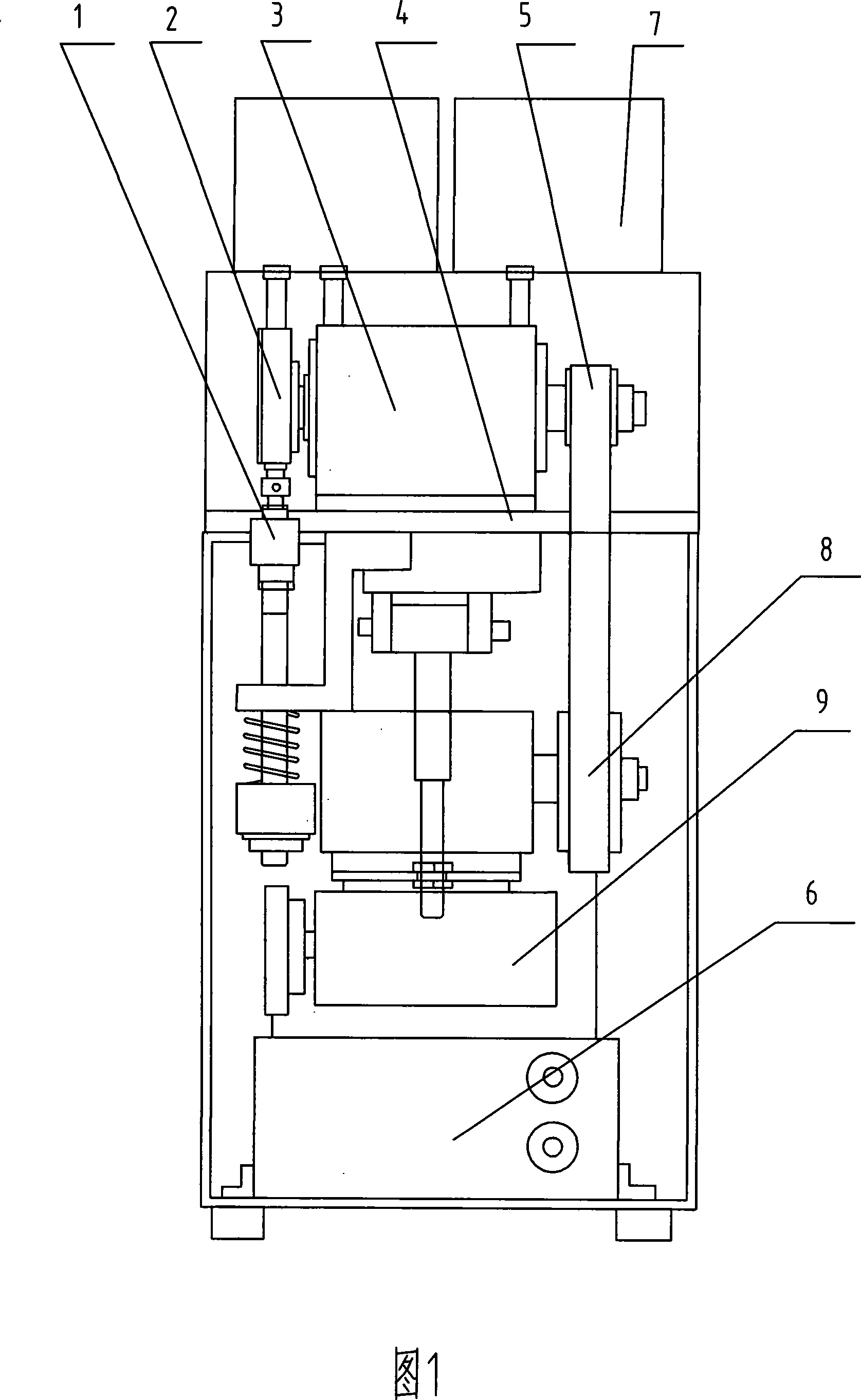

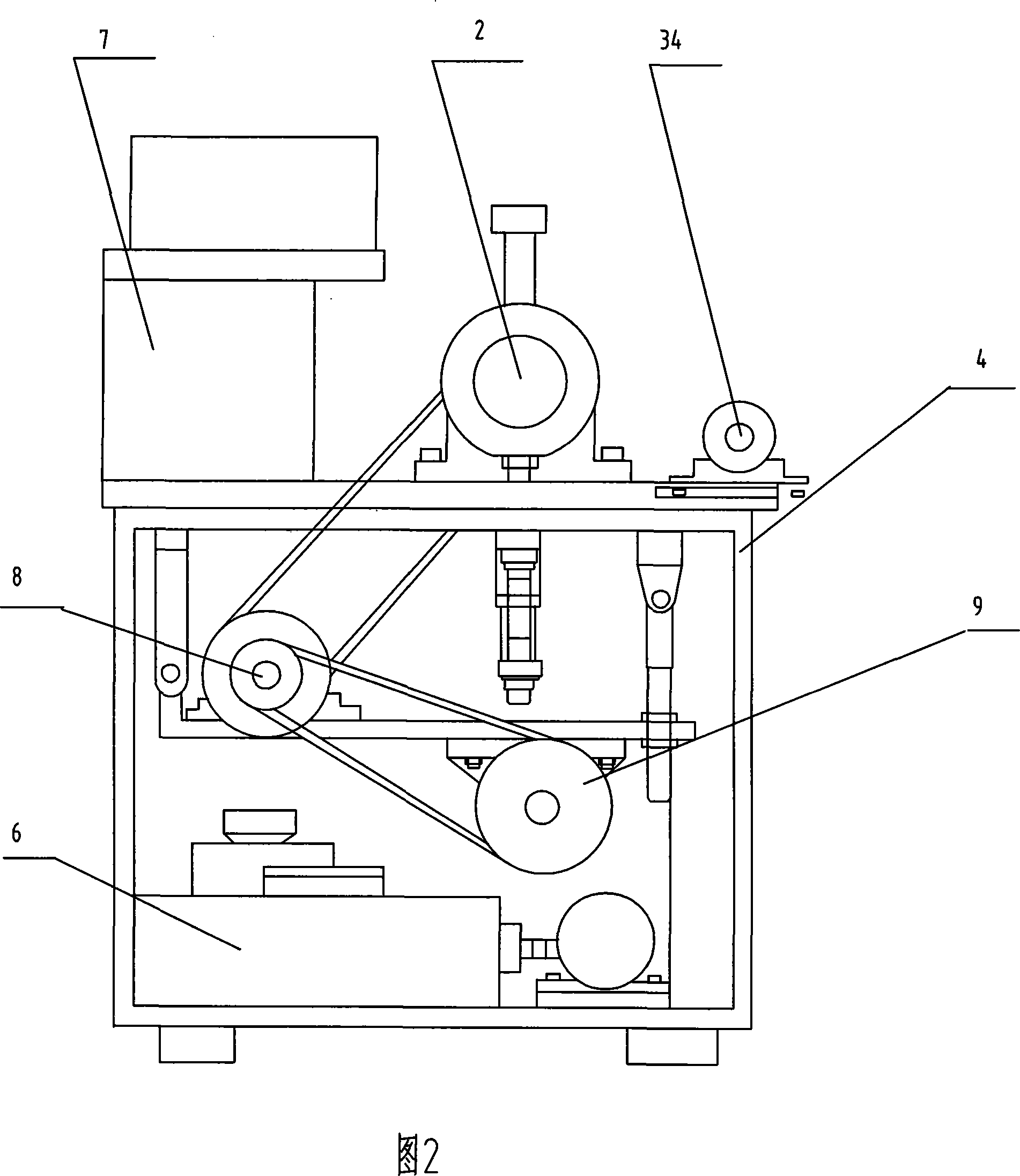

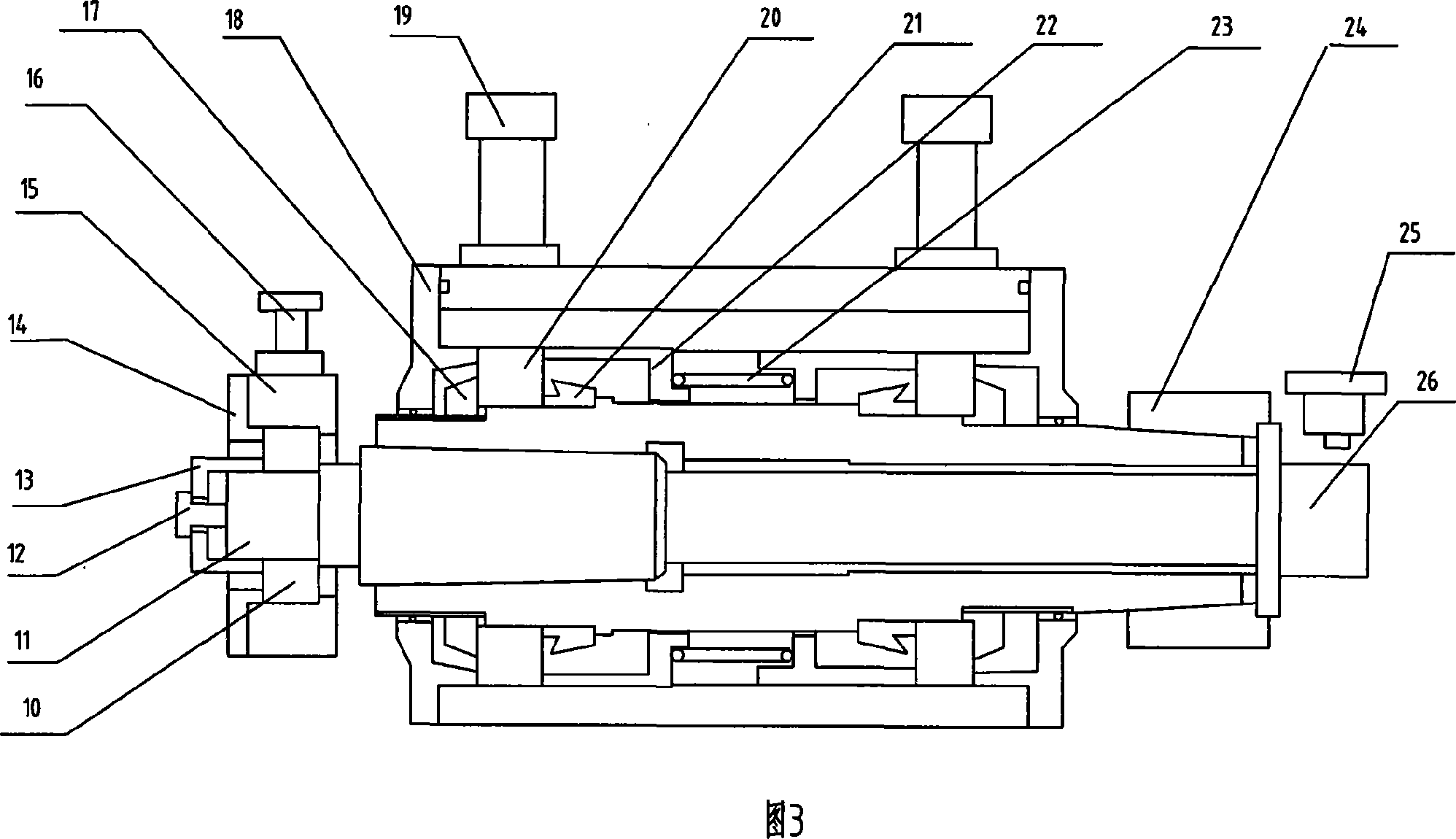

[0023] The embodiment of the present invention sealed bearing grease leakage temperature rise dustproof performance testing machine is provided with a test head part 2, a test spindle part 3, a loading system 1, a frame part 4, a transmission part 5, a lubrication system 6, and an electrical and control box 7 And the electrical system and control system installed in the electrical and control box 7, the test spindle part 3, the loading system 1, the transmission part 5, the lubrication system 6, the electrical and control box 7 are all installed on the frame part 4, and the test head Part 2 is connected with loading system 1, loading system 1 provides the load required for the test, test head part 2 is connected with test main shaft part 3, test main shaft part 3 is connected with transmission part 5, and transmission part 5 provides the power and speed required for the test , the lubrication system 6 is connected with the test spindle part 3 to realize the lubrication and cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com