Fixing device of battery

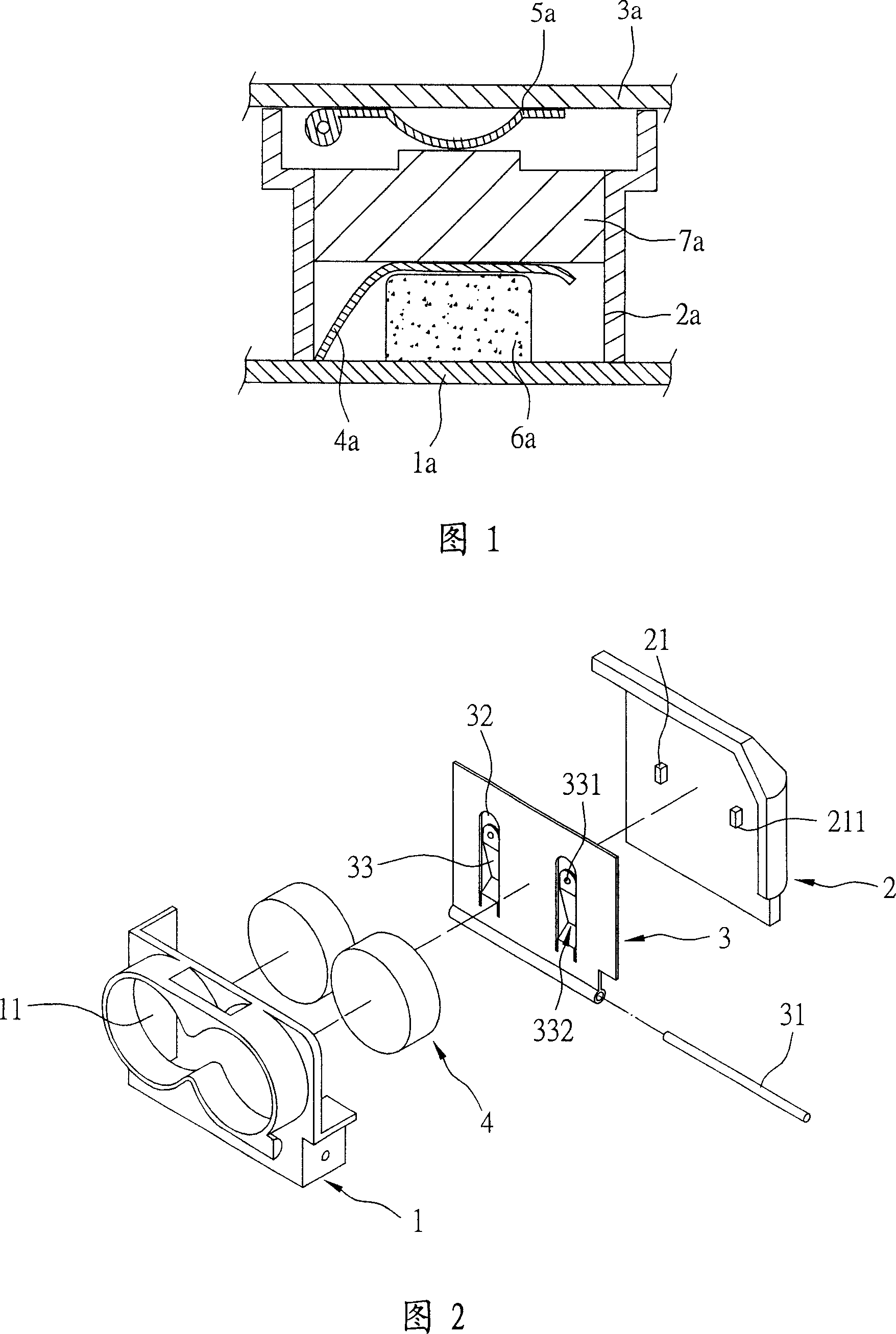

A fixing device and battery technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of the battery cover 3a being difficult to cover, increase the manufacturing process, increase the production cost, etc., and achieve easy use, cost reduction, pre- The effect of increasing the pressure stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

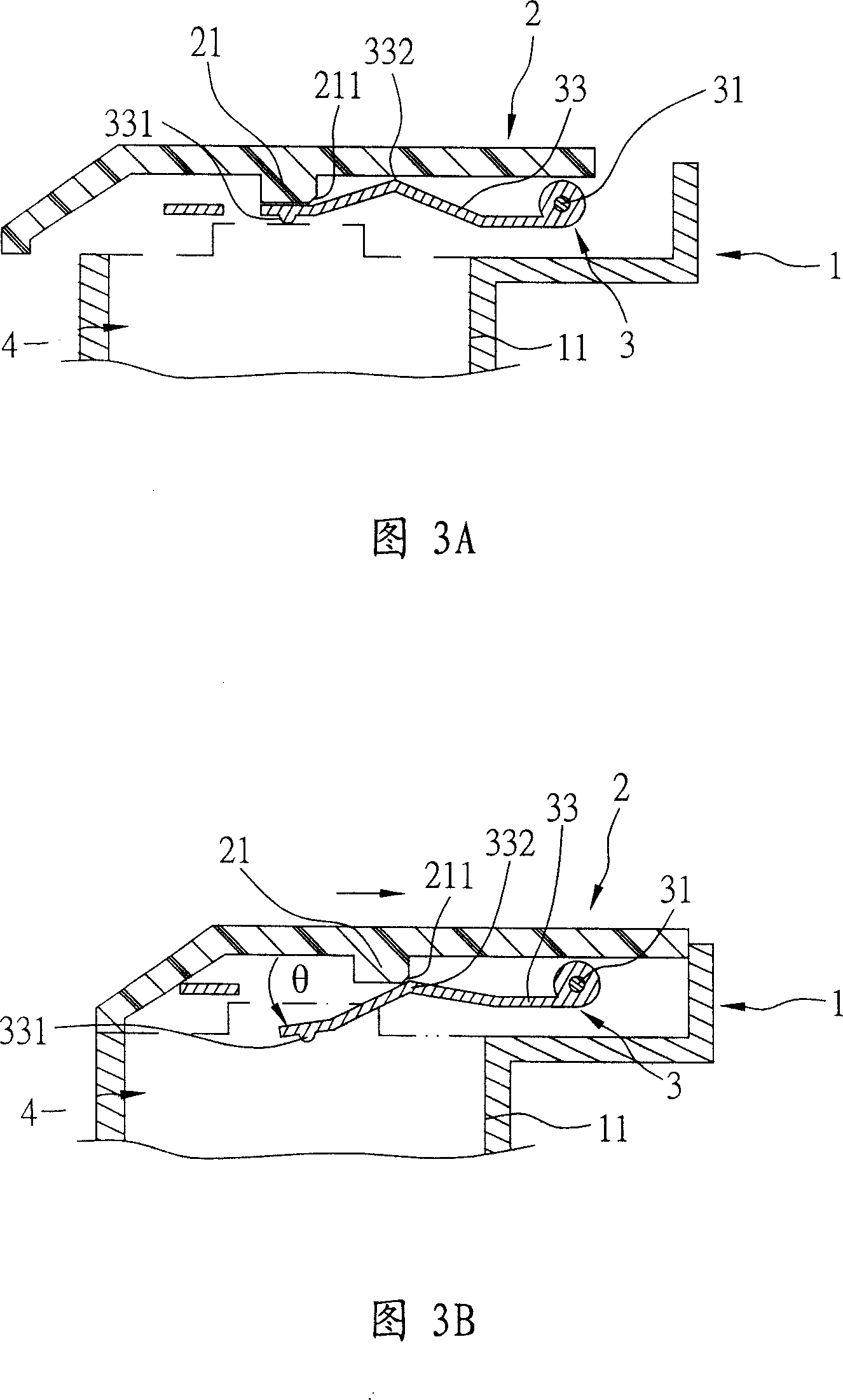

[0036] Please refer to FIG. 2 , FIG. 3A and FIG. 3B , the present invention provides a battery fixing device, which can be installed on an electronic device. The fixing device includes a bracket 1 , a shielding cover 2 and a battery spring 3 .

[0037] The bracket 1 is made of insulating material, and an accommodating space 11 with openings at both ends is formed inside the bracket 1. The accommodating space 11 and the bottom of the bracket 1 are connected to a battery holder (not shown in the figure), and in the accommodating space 11 The second battery 4 is accommodated, and the electrodes at the bottom of the second battery 4 are in contact with the shrapnel of the battery seat (not shown) to form an electrical connection.

[0038] The shielding cover body 2 is slidably assembled on the top of the bracket 1, and the shielding cover body 2 is provided with two square elastic spring shifting blocks 21, and the two elastic spring shifting blocks 21 are integrally formed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com