A high dynamic control system and method for solenoid valves based on voltage pulse width modulation technology

A control system, pulse width modulation technology, applied in valve details, valve devices, engine components, etc., can solve the problems of voltage source switching, weak solenoid valve, and not considering the working stroke of solenoid valve spool, etc., to reduce the opening and closing lag time, the effect of improving the dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

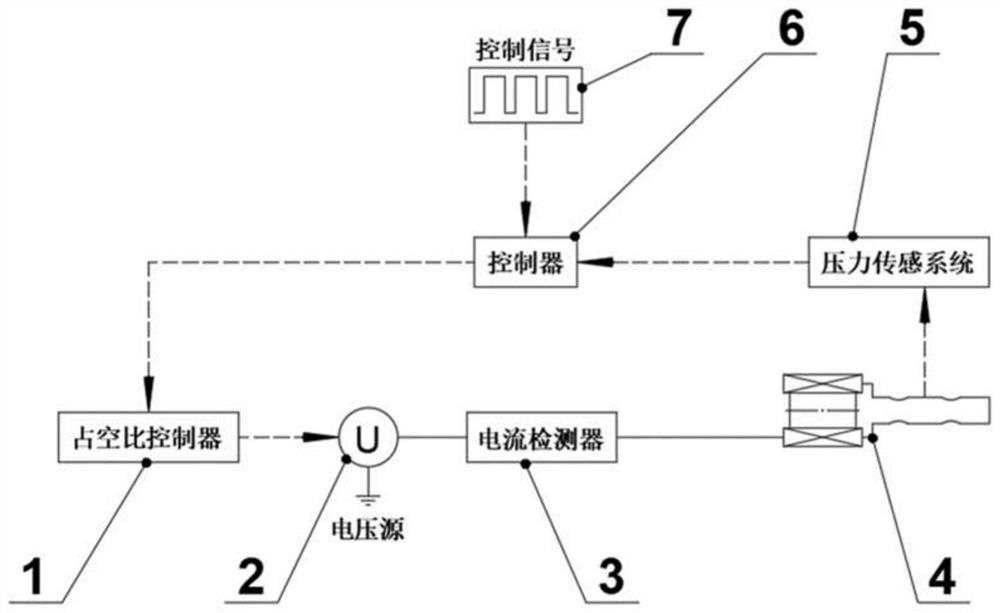

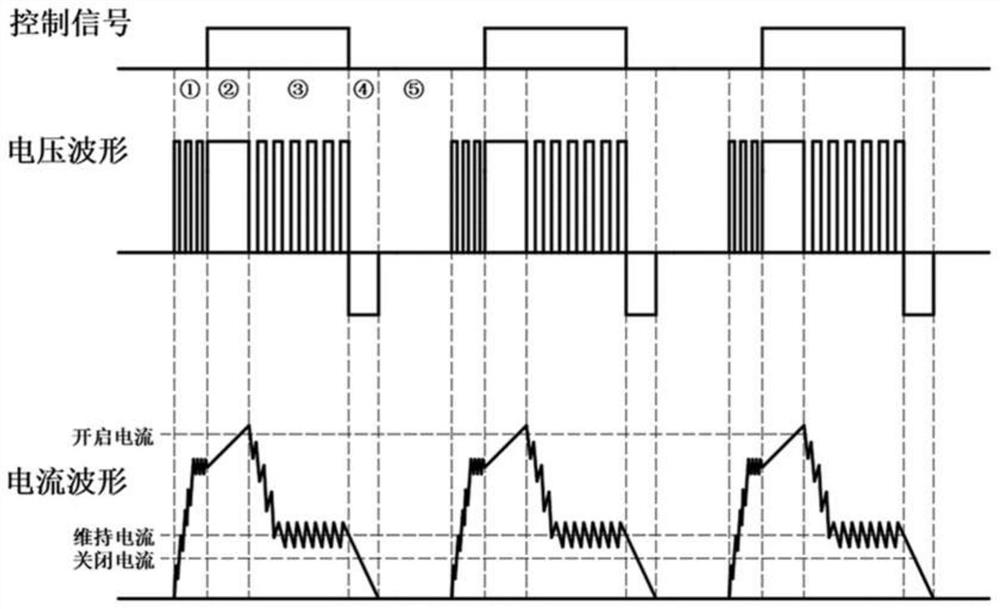

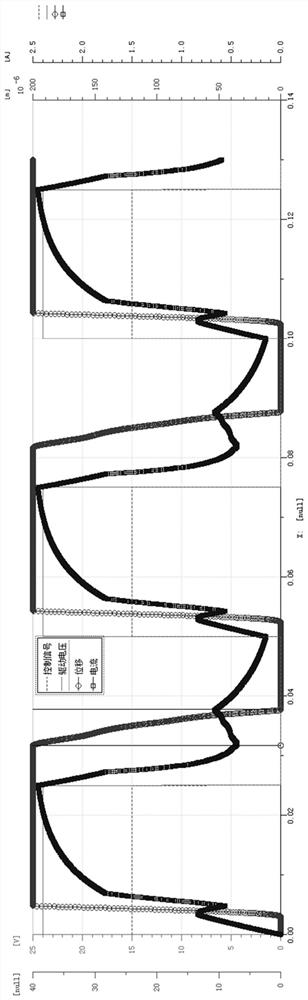

[0031] Such as figure 1As shown, the solenoid valve high dynamic control system based on voltage pulse width modulation technology in this embodiment includes a duty ratio controller 1, a voltage source 2, a current detector 3, a solenoid valve 4, a pressure sensing system 5, and a controller 6; The pressure sensing system 5 is connected with each working port of the solenoid valve 4 to obtain the pressure state of each working port of the solenoid valve in real time; the controller 6 is connected with the pressure sensing system 5 to obtain the data in the pressure sensing system 5 in real time, and the controller 6 The system on-current and off-current in the current state can be calculated according to the acquired data, the controller includes a control signal generation unit, and the control signal generation unit generates a control signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com