Heat shield with ceramic fiber structure

A technology of ceramic fiber and heat shield, which is used in electromechanical devices, electrical components, liquid fuel engines, etc., can solve the problem that the low-pressure cooling water circulation structure cannot be realized, it is difficult to cast internal water holes, and it is easy to form air holes and slag holes, etc. problems, to achieve a wide range of applications, save maintenance costs, reduce heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Amend the following in accordance with the amended claims

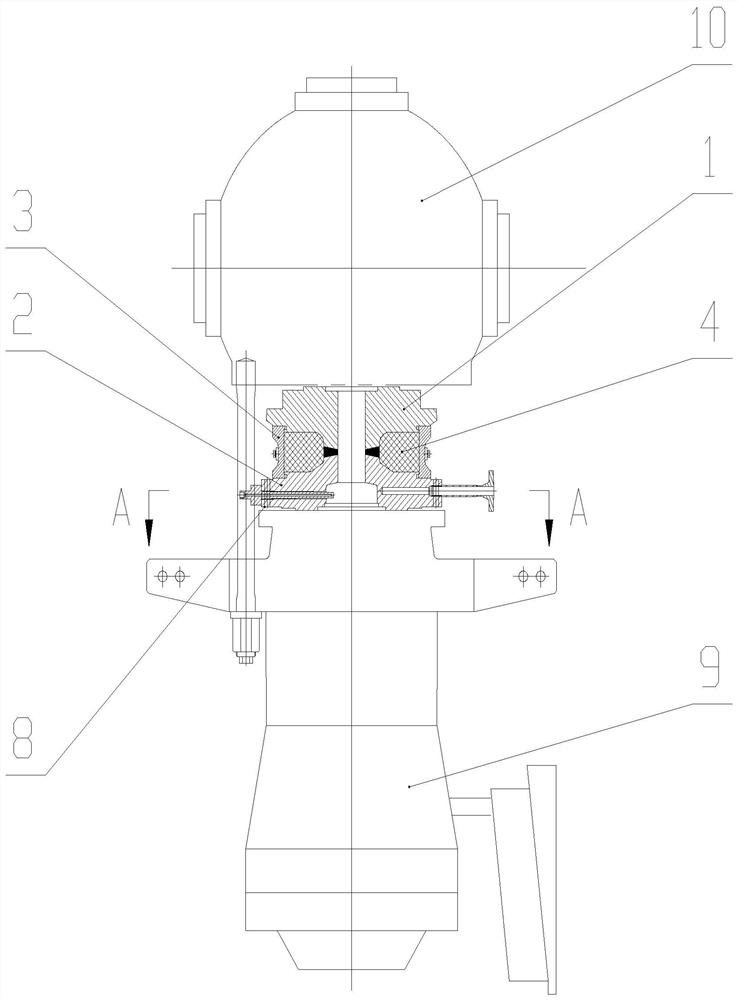

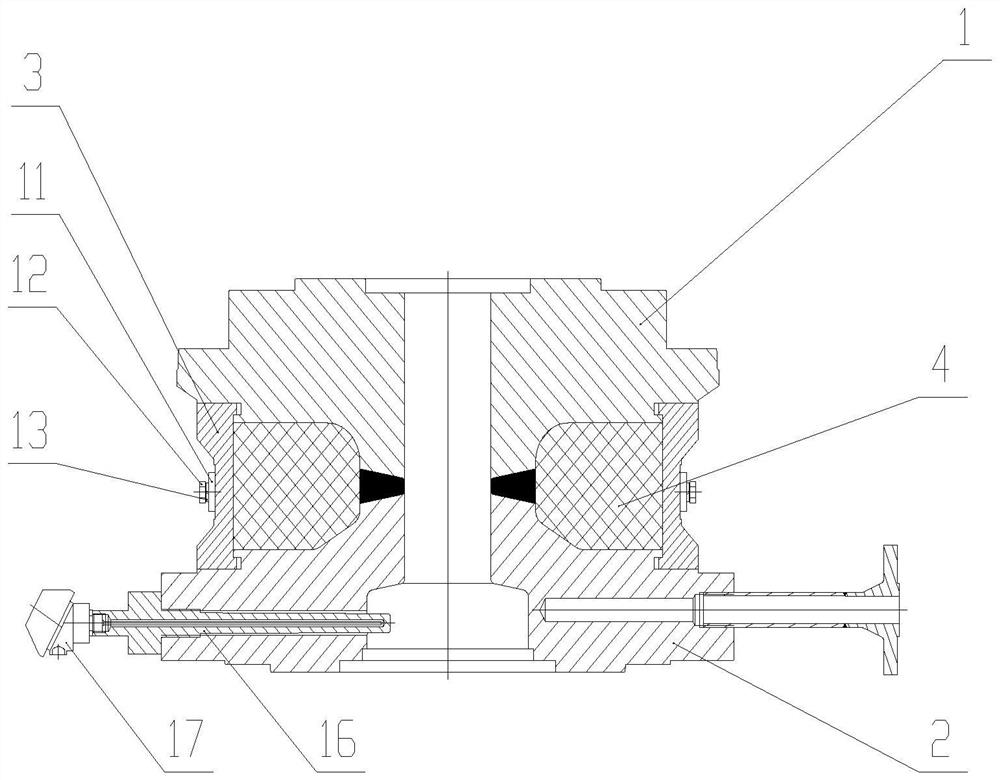

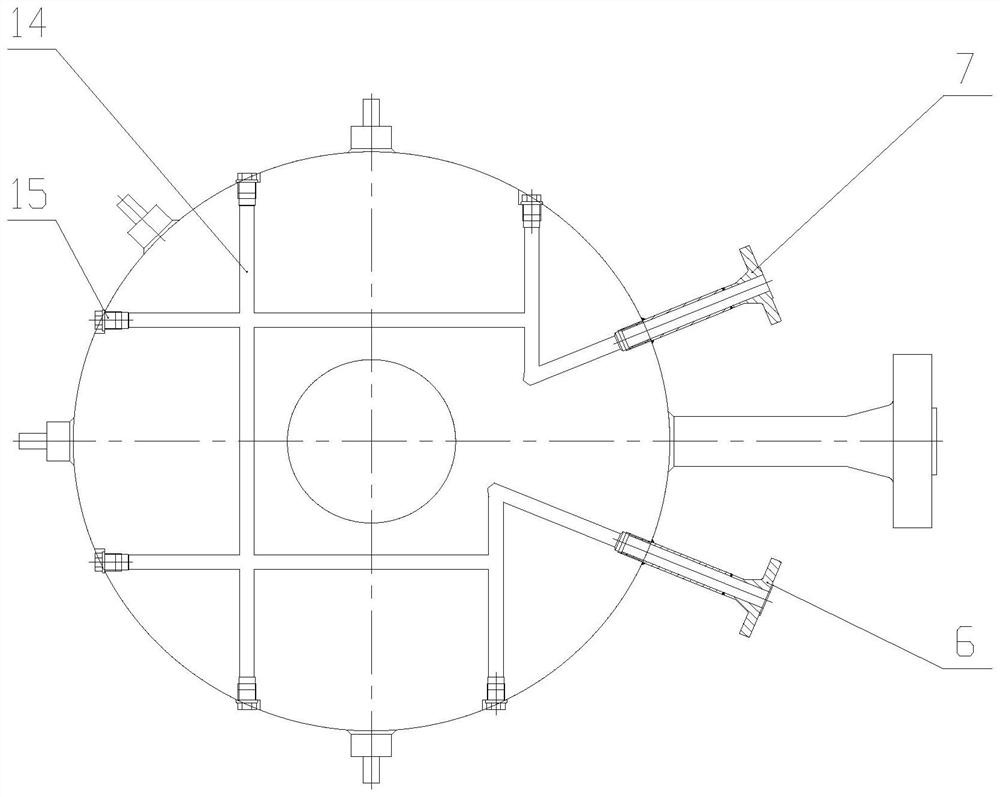

[0015] Such as figure 1 As shown, a heat shield with a ceramic fiber structure, the upper part 1 of the heat shield and the lower part 2 of the heat shield are welded and fixed together, and the outer edge of the upper part 1 of the heat shield and the lower part 2 of the heat shield is installed with a support ring 3 for heat insulation The cavity formed by the upper part 1 of the screen, the lower part 2 of the heat shield and the inner side of the support ring 3 is filled with ceramic fiber 4 heat insulation material. The two petals of the support ring 3 are fixed by bolts 12 and spring washers 13, and the lower part 2 of the heat shield has a plurality of low-pressure internal water holes 14 interconnected with each other, such as image 3 As shown, the low-pressure internal water hole 14 is externally blocked with a screw plug 15, and there are low-pressure cooling water inlet pipes 6 and outlet pipes 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com