Duplex winding asynchronous motor

A technology of asynchronous motors and double windings, applied in the field of electric motors, can solve the problems of unsatisfactory speed regulation effect and high cost of AC frequency conversion speed regulation, and achieve the convenience of energy-saving transformation, the effect of energy-saving transformation and energy-saving effect, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

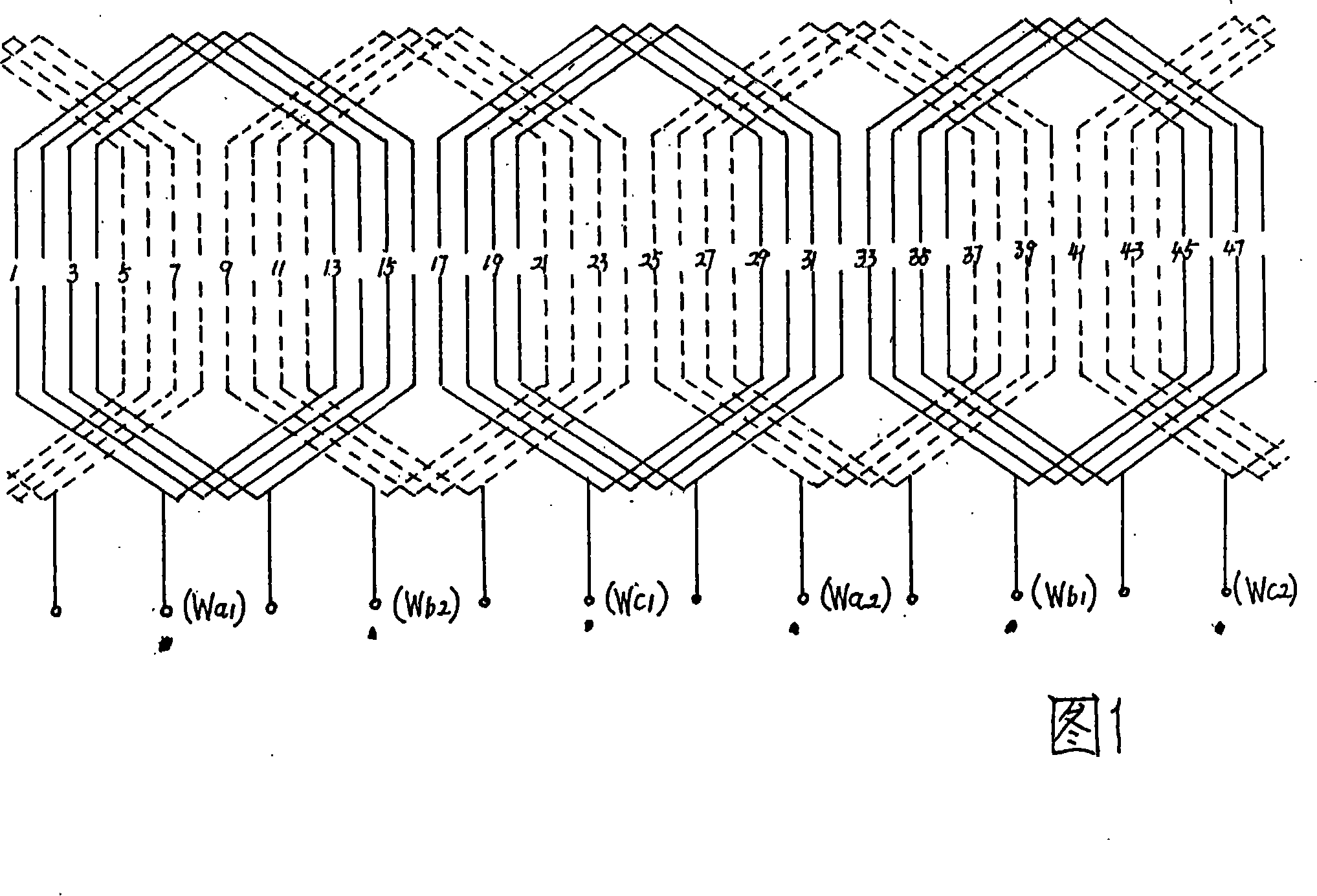

[0012] The stator of this embodiment has 48 slots, and the stator winding is a quadrupole winding, as shown in FIG. 1 .

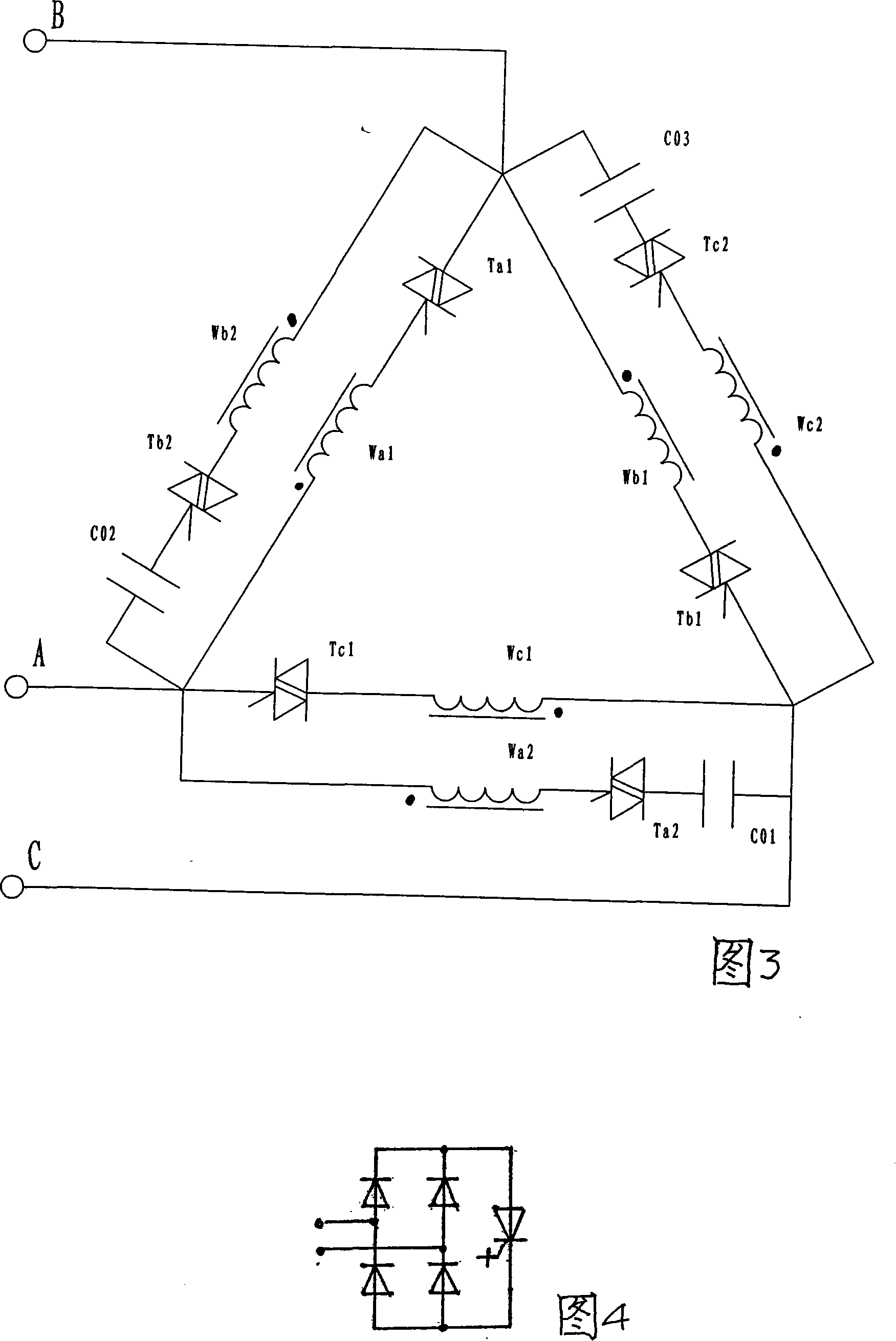

[0013] A double-winding asynchronous motor includes a stator and a rotor. There are main windings and auxiliary windings arranged in the stator. The three-phase windings Wa1, Wb1, Wc1 of the main winding and the three-phase windings Wa2, Wb2, Wc2 of the auxiliary winding are two sets of single-layer arrangements. The three-phase stator winding, the number of coil elements contained in the main winding and the auxiliary winding are the same, and the windings of the same phase of the main and auxiliary windings are arranged at a distance of 360° from each other (except for two-pole motors, they are all spaced at 360°); the main The three-phase winding Wa1, Wb1, and Wc1 of the winding form a delta connection; the first end of the A-phase winding Wa2 of the auxiliary winding is connected to the first end of the A-phase winding Wa1 of the main winding, and the en...

Embodiment 2

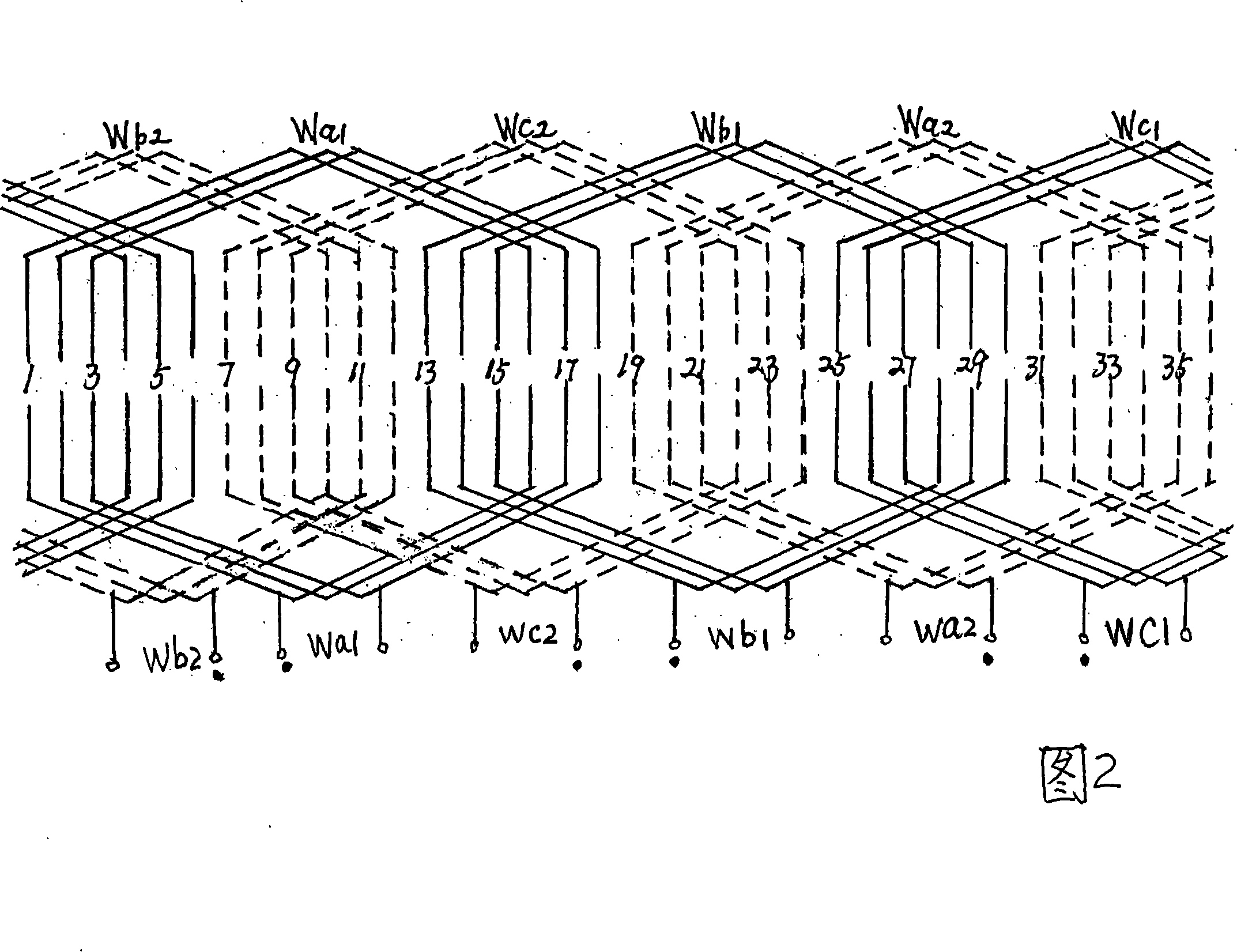

[0015] The stator of this embodiment has 36 slots, and the stator winding is a two-pole winding, as shown in FIG. 2 .

[0016]A double-winding asynchronous motor includes a stator and a rotor. There are main windings and auxiliary windings arranged in the stator. The three-phase windings Wa1, Wb1, Wc1 of the main winding and the three-phase windings Wa2, Wb2, Wc2 of the auxiliary winding are two sets of single-layer arrangements. The number of coil elements contained in the main winding and the auxiliary winding is the same, and the windings of the same phase of the main and auxiliary windings are arranged at a distance of 180° from each other (180° for only two-pole motors); the three phases of the main winding The phase windings Wa1, Wb1, and Wc1 form a delta connection; the first end of the A-phase winding Wa2 of the auxiliary winding is connected to the first end of the A-phase winding Wa1 of the main winding, and the end is connected to the C-phase winding Wc1 of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com