Motor vehicle with a roll-over bar assembly

A technology for automobiles and bows, which is applied in the field of automobiles with rollover protection bows, which can solve problems affecting the strength of the car body, and achieve the effects of increased rigidity, simplified installation, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

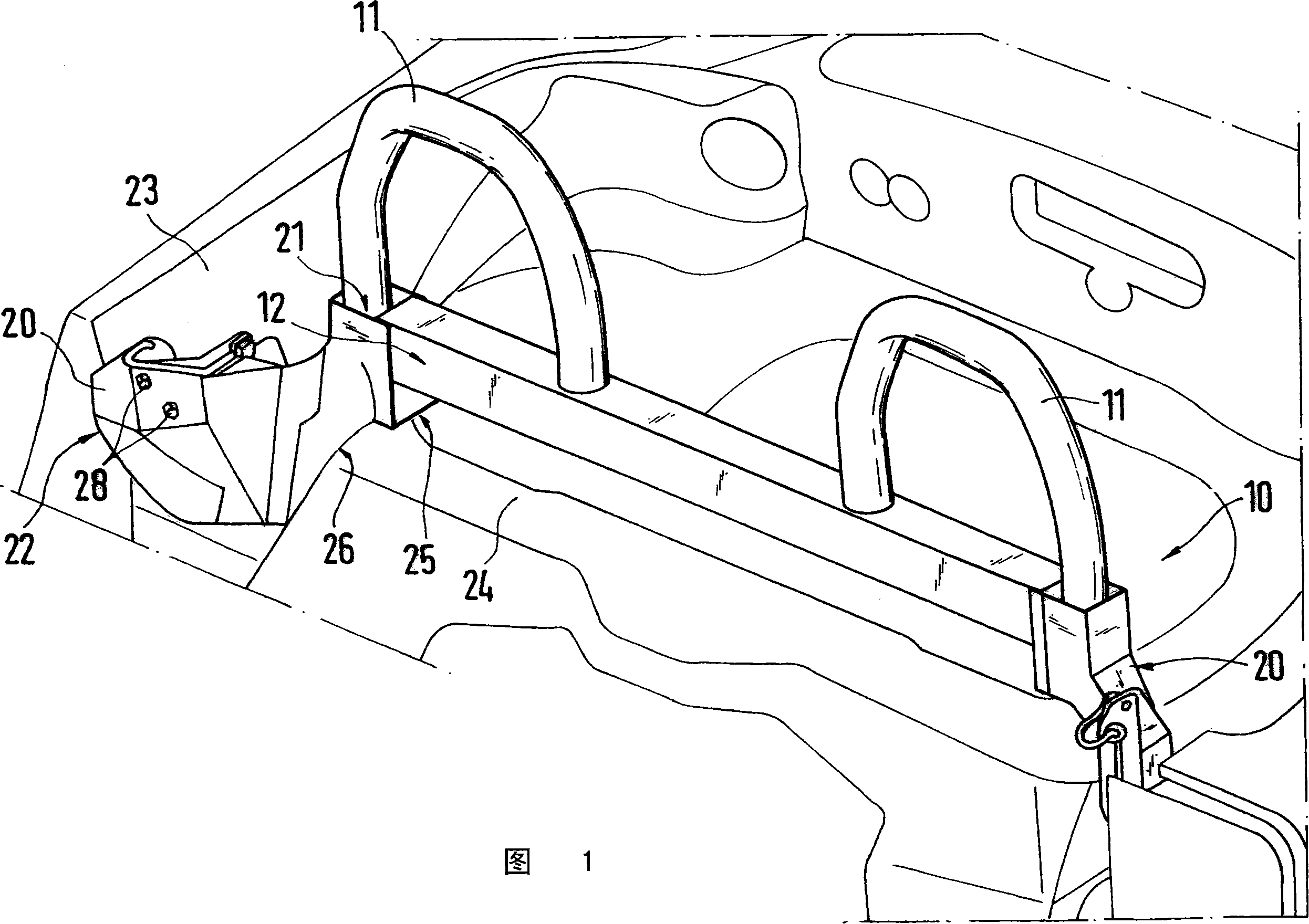

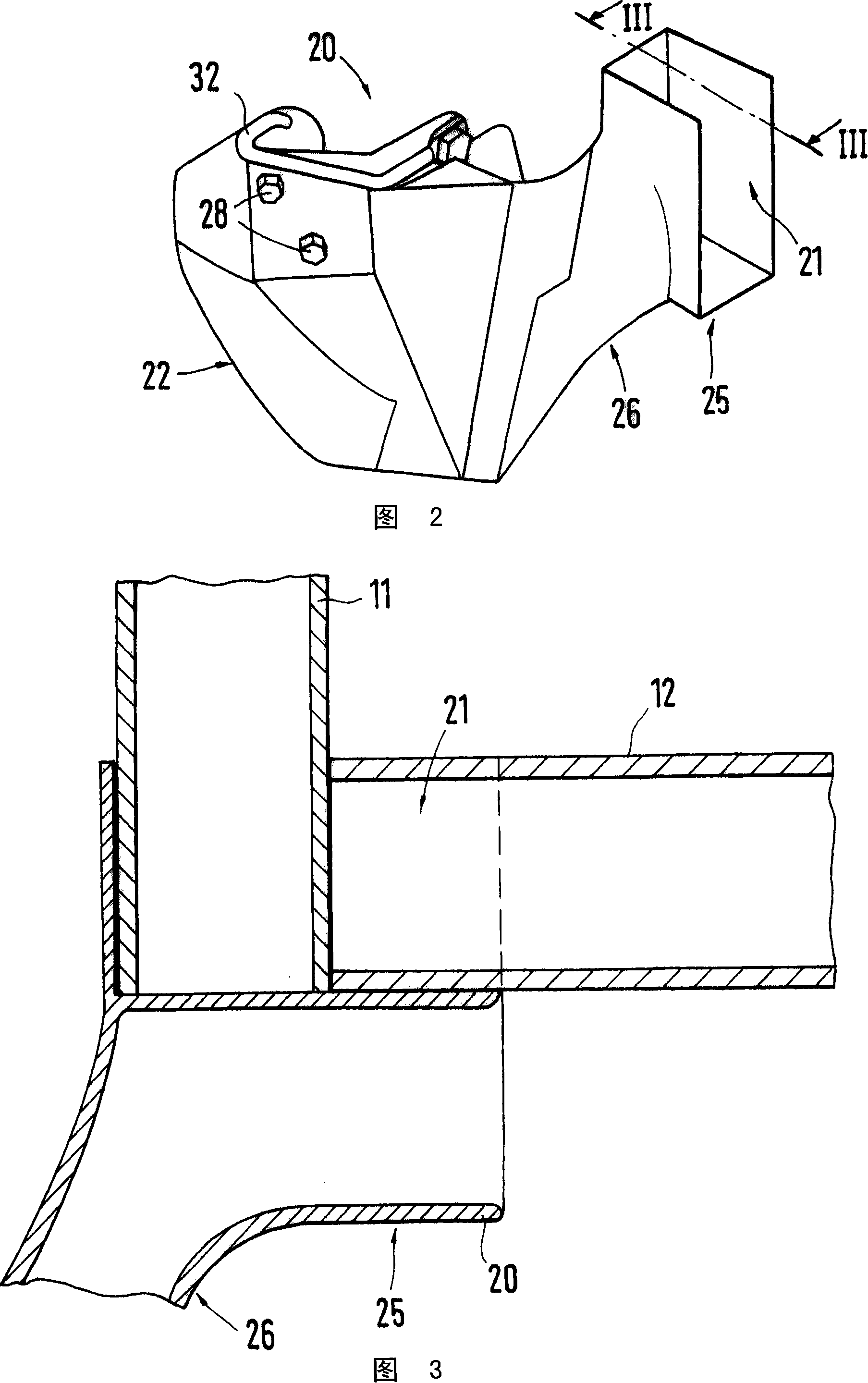

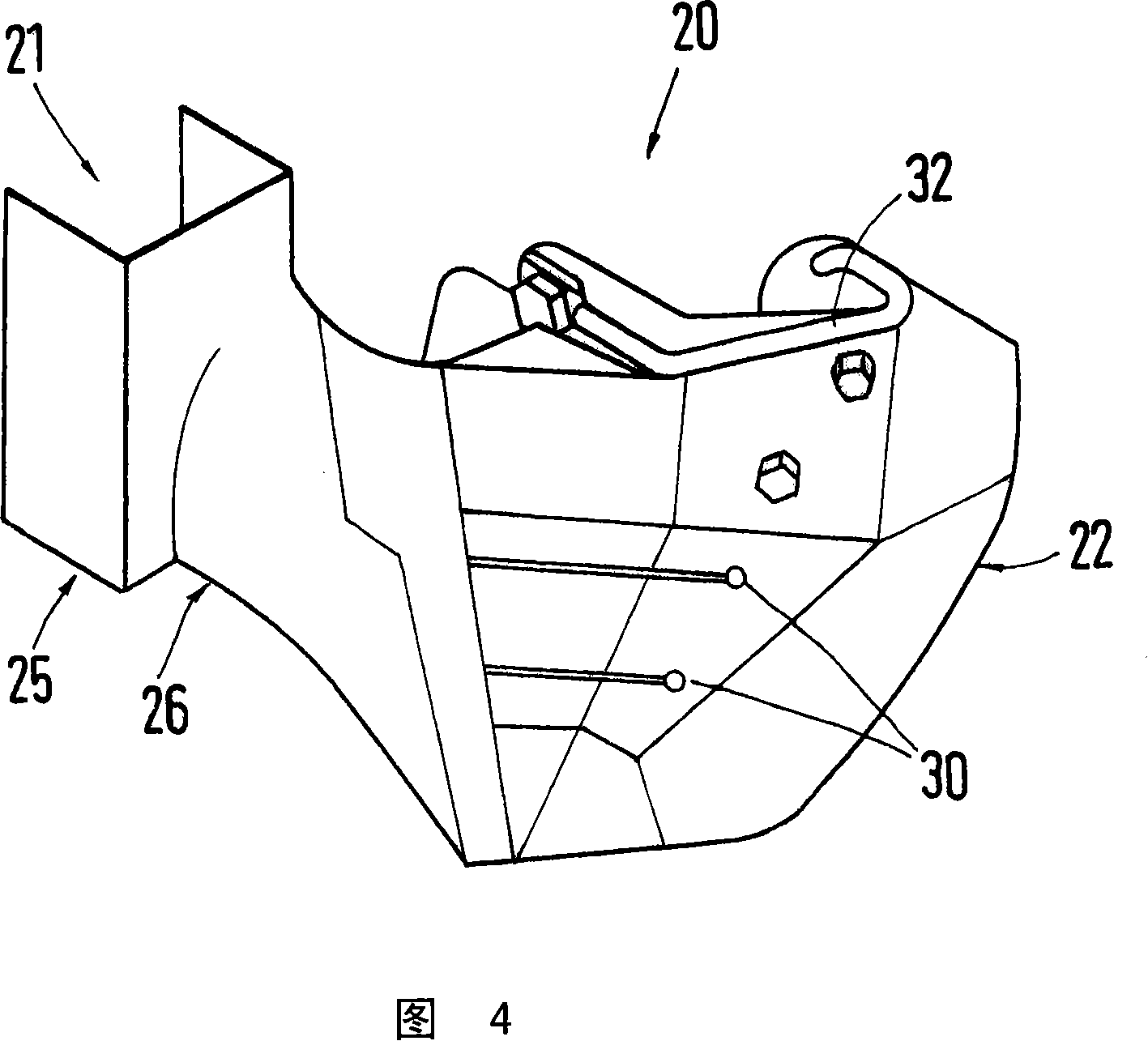

[0035] FIG. 1 shows a perspective view of a roll bar arrangement 10 according to the invention, shown here being installed in a motor vehicle. The roll bar arrangement 10 here comprises two U-shaped roll bars 11 , a cross member 12 and a connecting piece 20 with a fastening opening 21 . One end portion of the roll bar 11 and one end portion of the cross member 12 are respectively fixed in the fastening opening 21 . The connecting elements 20 arranged on both sides between the cross member and the inner wall of the vehicle body are designed mirror-symmetrically. At the contact surface 22 the connection part 20 is fastened to the outer body wall 23 . In an exemplary embodiment, the connecting part 20 is fastened on the outer body wall on the one hand in a form-fitting manner, but additionally by means of screws 28 .

[0036] The connection part 20 is supported in the horizontal direction via the contact surface 25 and additionally in the vertical direction via the contact surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com