Panel lighting test machine and detecting method thereof

A testing machine and panel technology, which is applied in the direction of optical instrument testing, machine/structural component testing, electrical measurement, etc., can solve the problems of increasing the process time of lighting detection, etc., and achieve the effect of shortening the process conversion time and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

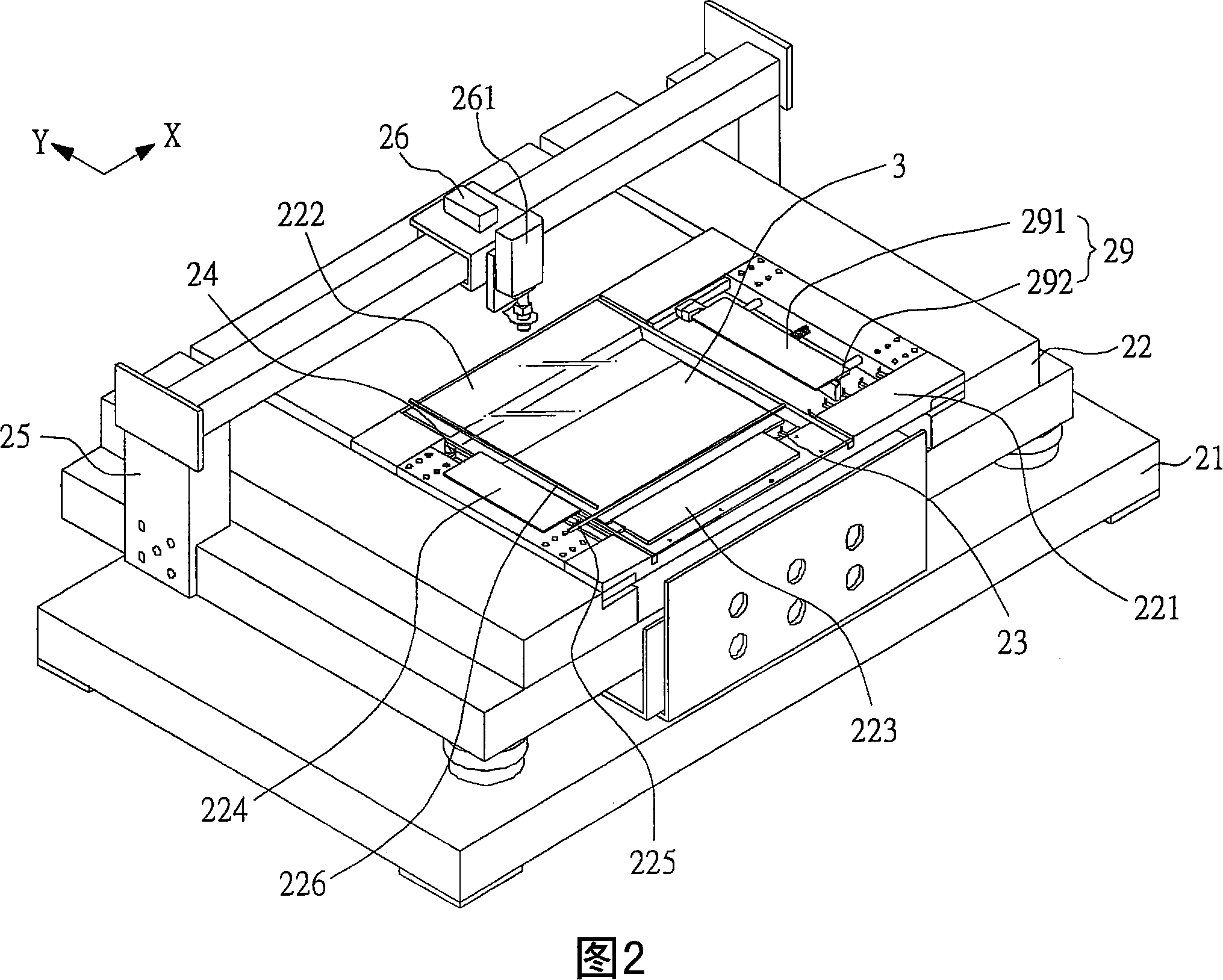

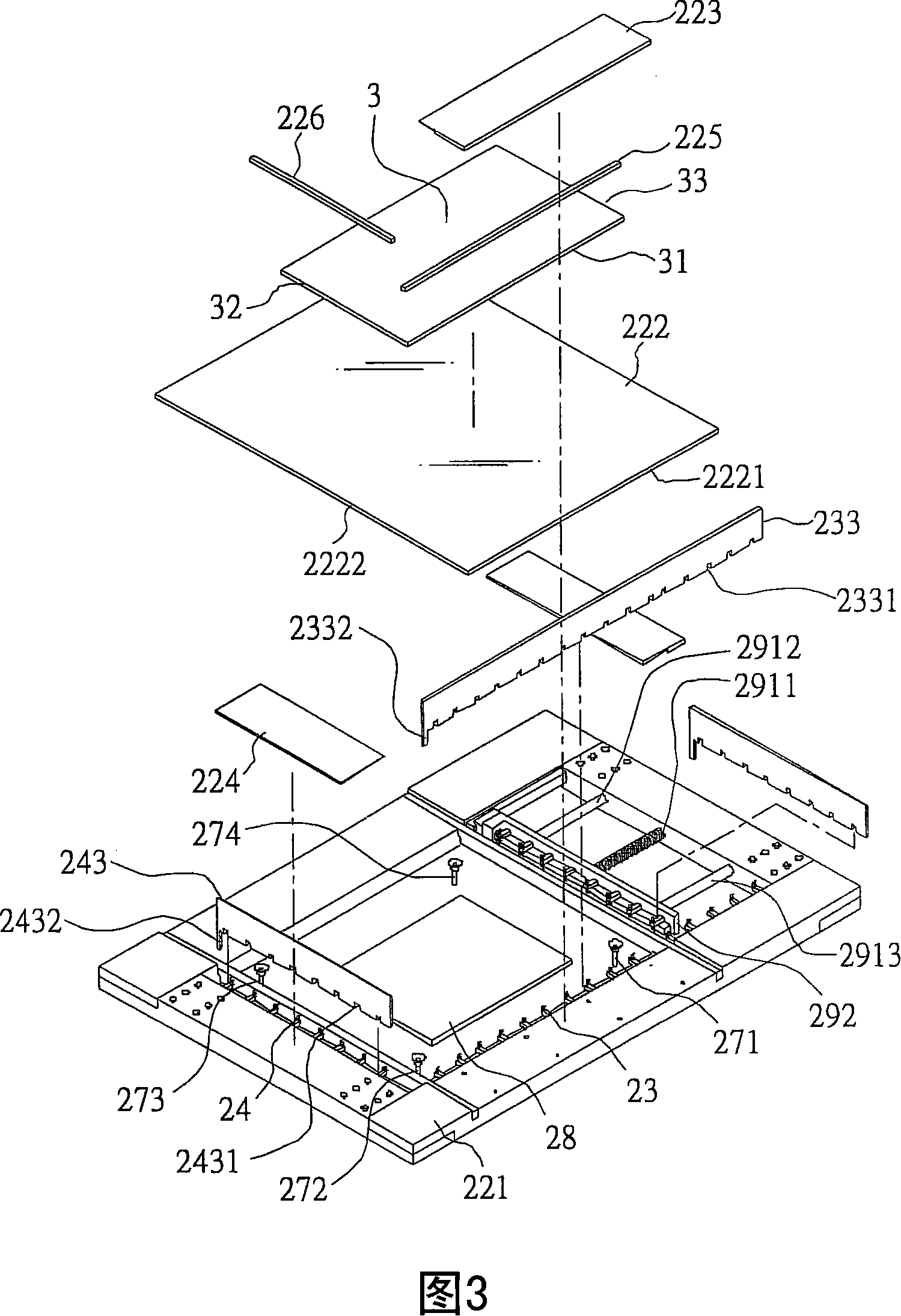

[0040] First, please refer to FIG. 2 and FIG. 3 , wherein FIG. 2 is a perspective view of a panel lighting tester according to an embodiment of the present invention, and FIG. 3 is an exploded view of a panel lighting tester according to an embodiment of the present invention. A panel lighting testing machine according to an embodiment of the present invention includes: a base 21 , a panel bearing seat 22 , a plurality of lighting testing parts 23 , 24 , a support frame 25 and a laser repair unit 26 . Wherein, the panel bearing seat 22 is disposed on the base 21 and reciprocates on the base 21 along the Y direction in FIG. 2 . In addition, the panel carrier 22 includes a rectangular frame body 221, a carrier plate 222 and a plurality of positioning units 223, 224, the carrier plate 222 is arranged on the rectangular frame body 221, and the plurality of positioning units 223, 224 are respectively arranged on the sides of the carrier plate 222. Two sides 2221,2222. In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com