Climbing cone type triangular cantilever bracket

A technology of cantilever brackets and triangular trusses, applied in the field of brackets, can solve problems such as difficulty in ensuring welding quality and safety of high-altitude operations, long time for bracket erection and dismantling, and affecting process transition time, etc., to shorten process transition time and improve construction efficiency High effect with little effect on appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

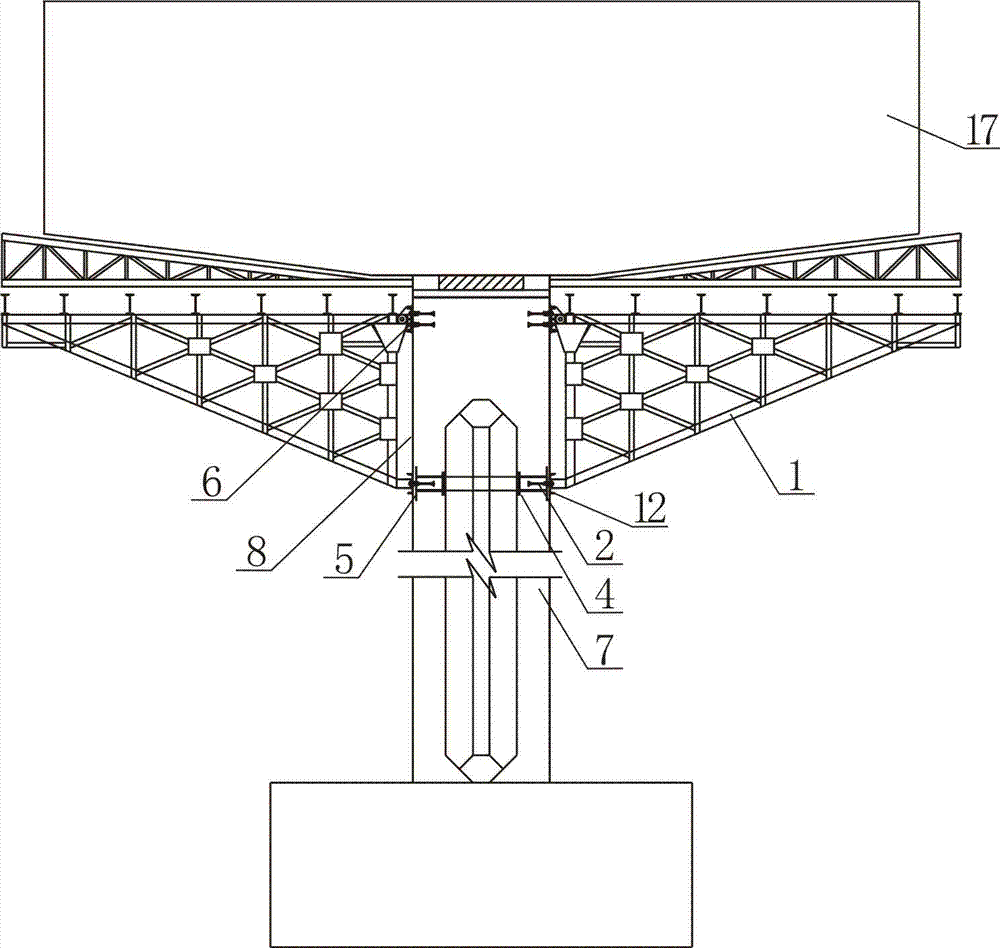

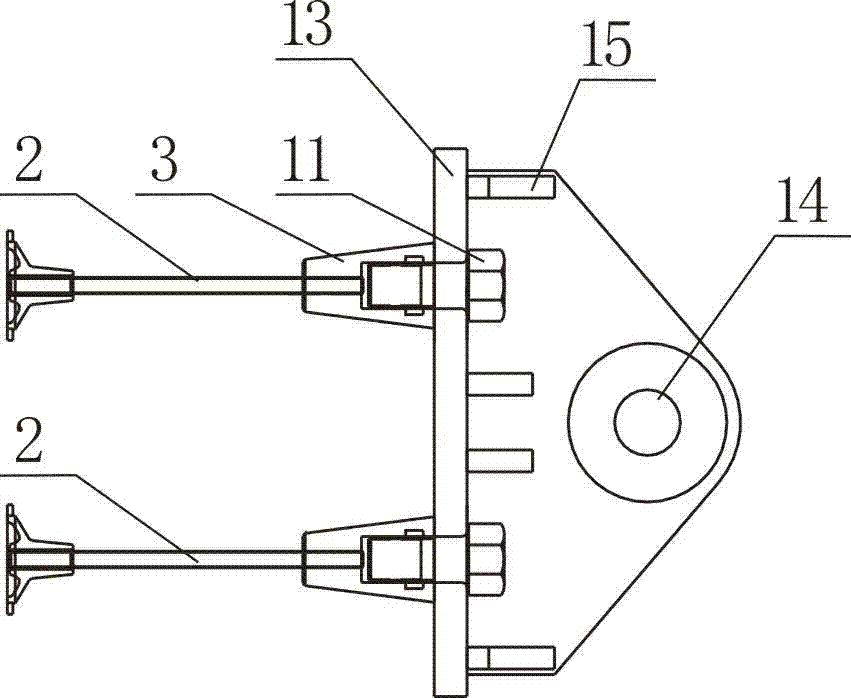

[0023] Such as figure 1 , 3 As shown in , 4, the climbing cone type triangular cantilever support is composed of a tripod 1, climbing cone bolts 2, conical nuts 3, steel plates 5, steel mesh 4 and fixing seats 6, and the climbing cone bolts 2 are embedded horizontally On the upper part of the pier body 7, the steel plate 5 is vertically pre-buried in the pier body 7 and close to the front end of the climbing cone bolt 2, the surface of the steel plate 5 is perpendicular to the climbing cone bolt 2, and the steel mesh 4 is arranged on the climbing cone bolt 2, the tapered nut 3 is pre-embedded in the pier body 7, one end is threaded with the front end of the climbing cone bolt 2, and the other end is flush with the side 8 of the pier body.

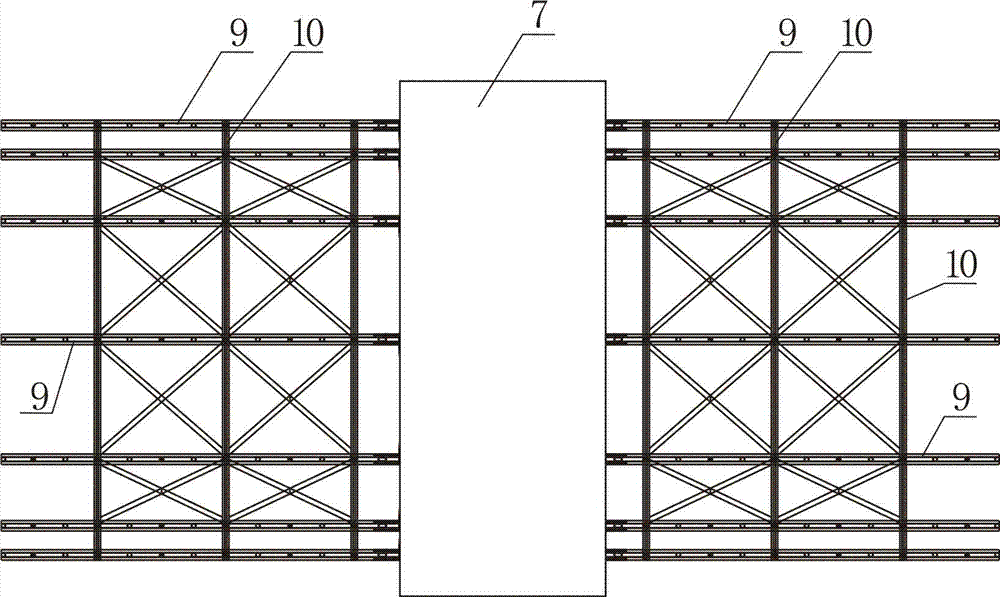

[0024] Such as figure 1 , 2 , 5, the tripod 1 is composed of 7 triangular trusses 9 and cross-links 10, the length of the right-angled side of the triangular truss is 300cm, and the length of the other right-angled side is 750cm. A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com