Automatic switching method of belt conveying system flows

A system process, automatic switching technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of low production efficiency and long process switching time, to improve loading and unloading capacity, improve economic benefits, shorten the The effect of process switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the process automatic switching method of the belt conveying system of this embodiment, wherein the belt conveying system includes several processes and feeding trolleys, the automatic process switching method of the belt conveying system of this embodiment includes the following steps:

[0020] S1. Receive the command to switch the process, send the control signal, start the target process, and send the driving signal to drive the feeding trolley to the target position;

[0021] S2. It is detected that the feeding trolley reaches the target position, the interlock between the start-up processes is detected, and the original process stops working.

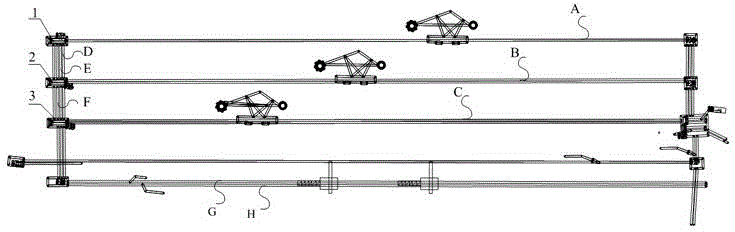

[0022] see figure 1 As shown, it is a schematic diagram of the belt conveying system of the present embodiment, at least including A, B, C, D, E, F, G, H belts, and the corresponding positions are respectively provided with a feeding trolley 1, a feeding trolley 2, and a feeding trolley. Feed trolley 3, among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com