Pulling and pushing device for a central buffer coupling of rail vehicles

A traction buffer and coupling technology, which is applied in the direction of traction devices, buffer vehicles, transportation and packaging, etc., can solve the problems of dragging, weakening of stabilizing effect of stabilizing hinges, impact, etc., and achieve the effect of avoiding the acceleration peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

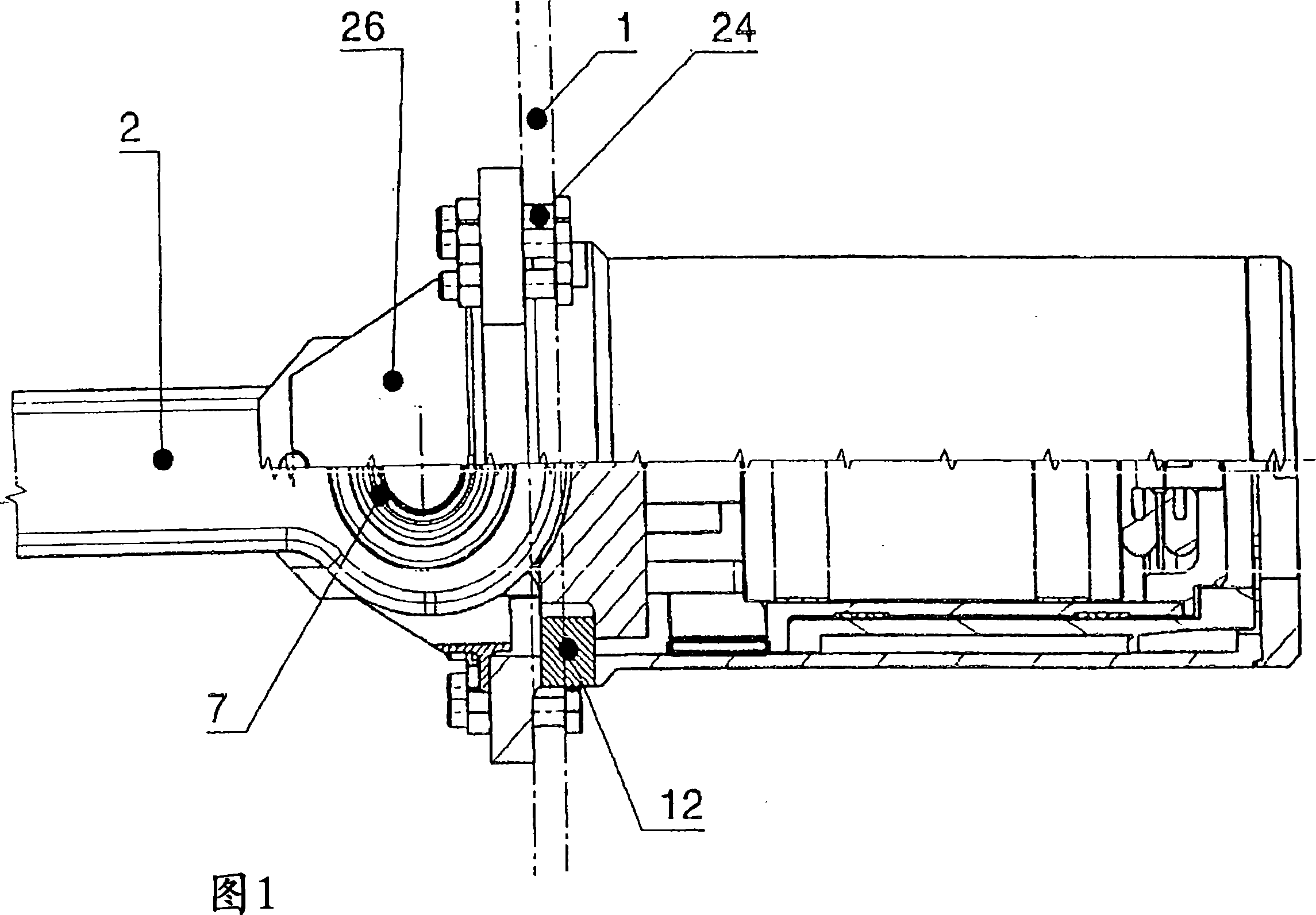

[0019] In FIG. 1, a flanged traction damper with a connecting arm for an intermediate damper coupling of a rail vehicle is shown in a top view in half section. The traction buffer device 100 is screwed to the undercarriage 1 of the rail vehicle via a screw connection part 24 . The connecting arm with the connecting head 2 is articulated on the hinge shaft 4 via the hinge gap spring damper 7 .

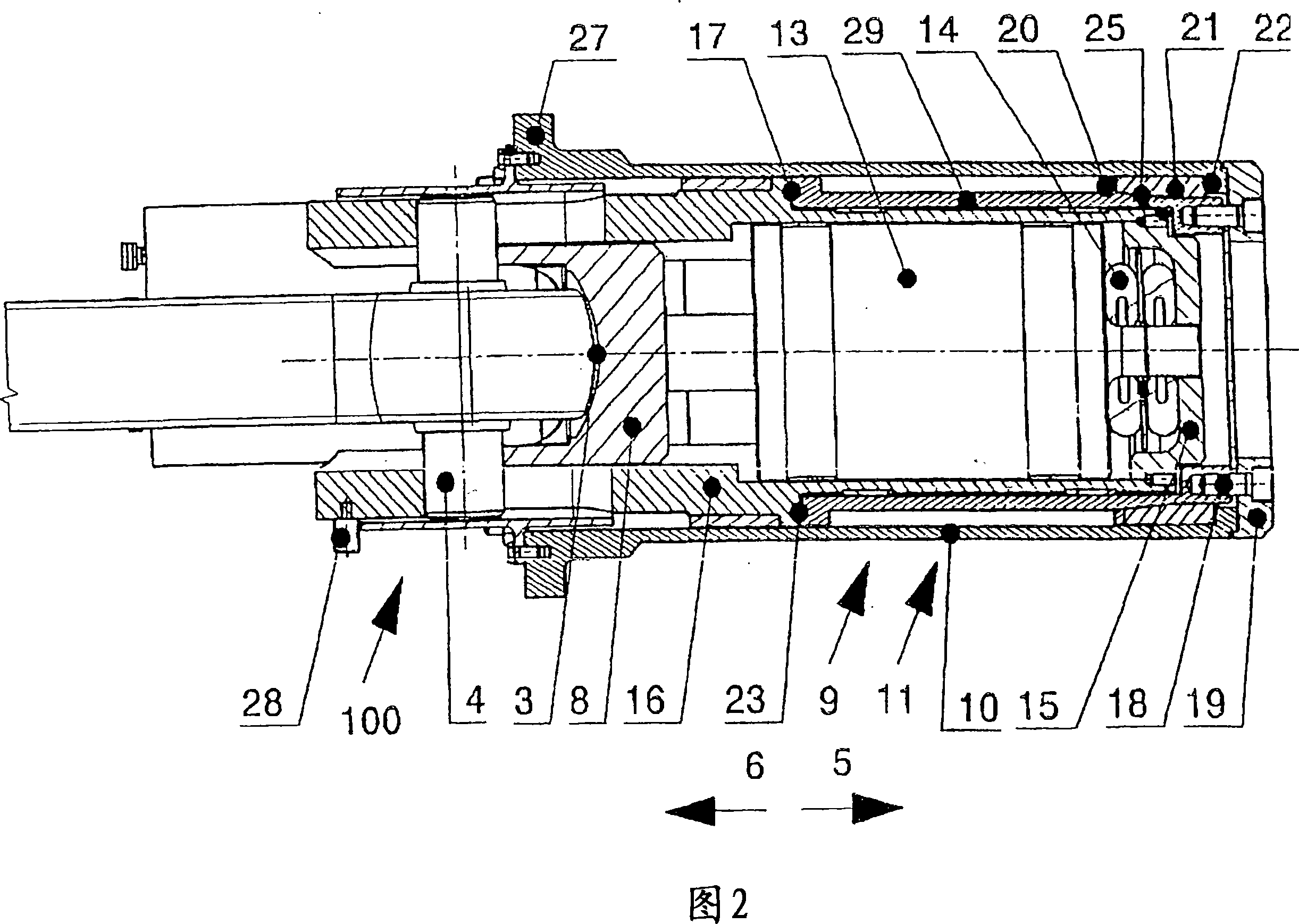

[0020] In FIG. 2 the traction damper is shown in side sectional view. The hinge 3 is supported by the end surface against the pressing plate 8, and the pressing plate transmits the pressing force to the reversible energy consumption system composed of the shock absorber 13 and the unloading spring 14 when the pressing plate is pressed, wherein, through the inner cover plate 15 towards The inner housing 16 provides support. The inner housing 16 is pressed against the deformation element 23 via the stop 17, and the deformation element is supported on the stop 22 of the outer housing 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com