Dust cleaning apparatus of laser cutting machine tool

A technology of laser cutting machine and dust removal device, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor dust removal effect, polluted indoor environment, dust floating, etc., and achieve the effect of fast dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

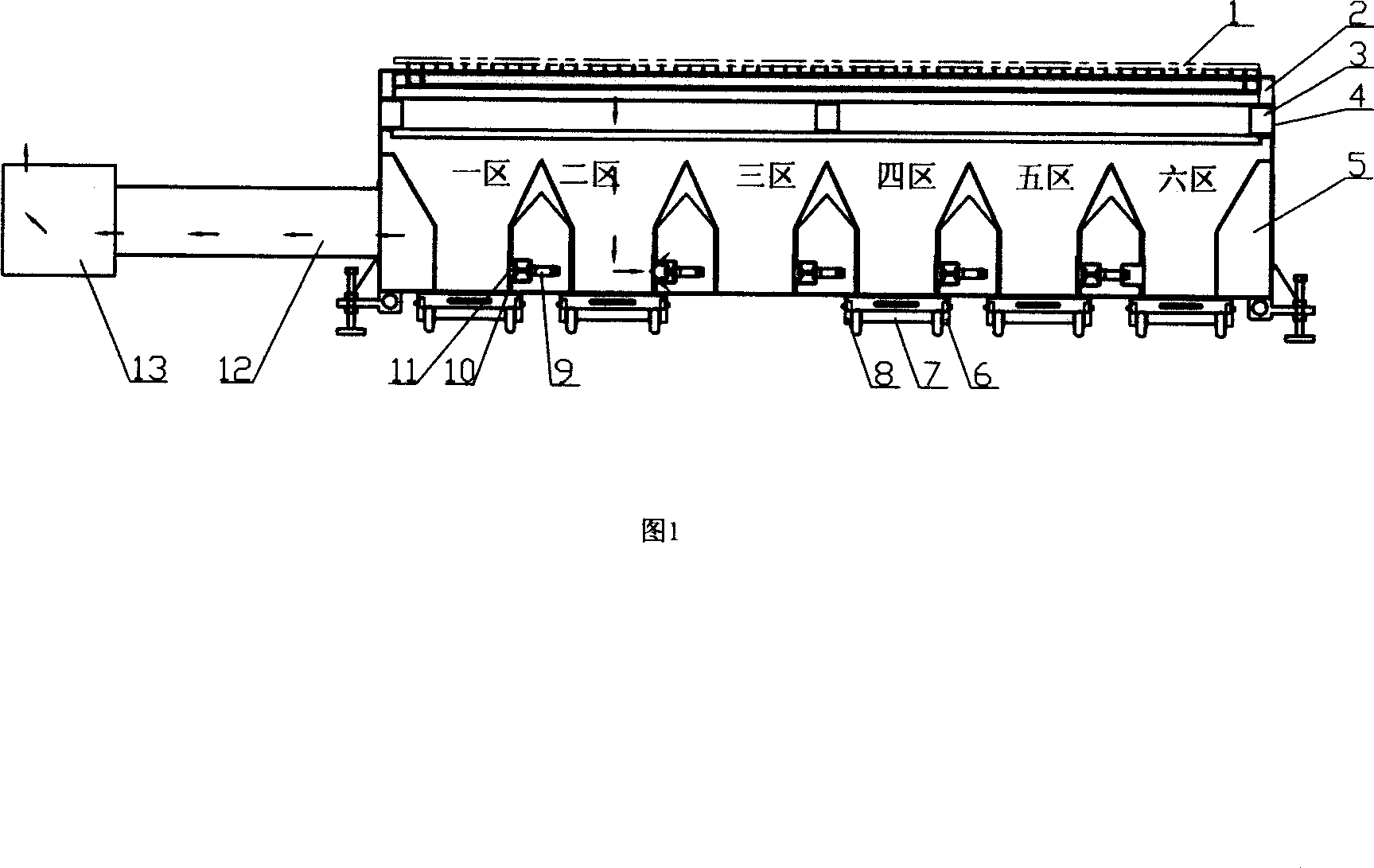

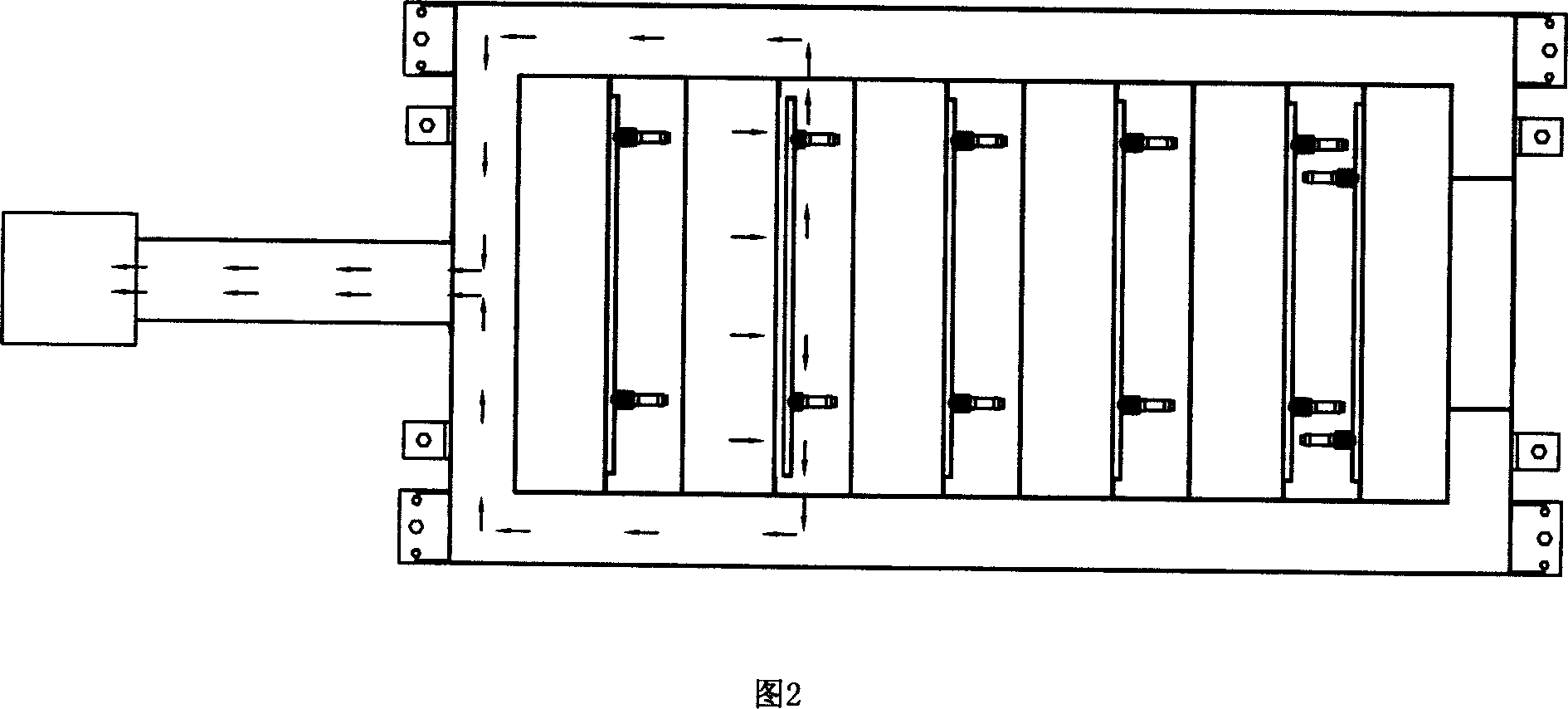

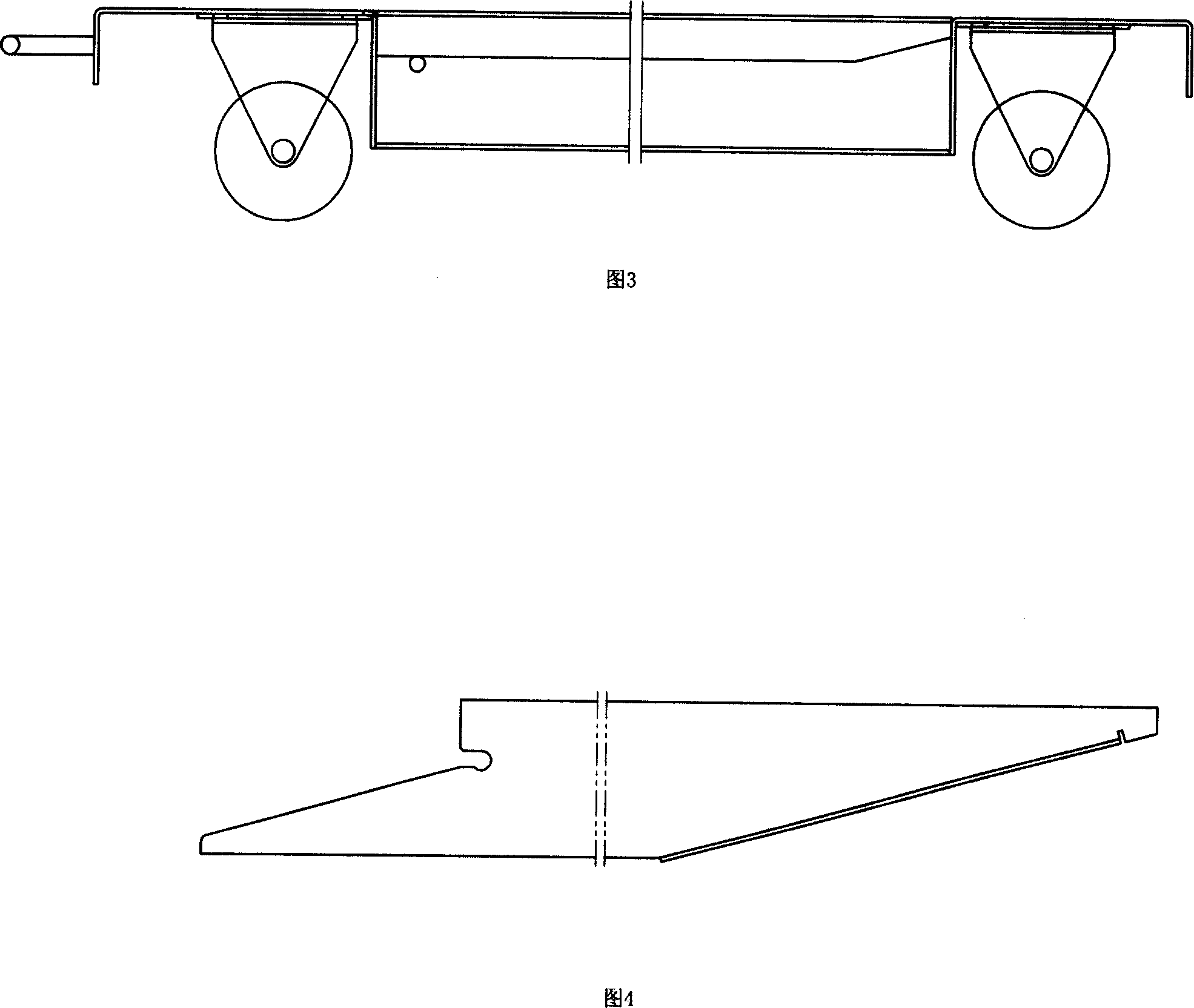

[0015] Please refer to Fig. 1 to Fig. 4, the laser cutting machine sub-area ventilation and dust removal device of the present invention includes a pedestal 5, a pedestal 2 mounted on the pedestal, a workpiece 1 placed on the pedestal 2, and a waste car right under the pedestal 5. Hanger 6, waste car left hanger 8, waste car 7, cylinder 9 and damper 10 are contained on the filter plate 11, and filter plate 11 is contained on the window of the connecting beam in the pedestal 5, and exhaust tube 12 and exhaust fan 13 are installed At the rear end of the pedestal 5, the support plate 3 and the guard plate 4 are installed in the middle of the stand 2 and the stand 5. The support plate 3 supports the stand 2, and the guard plate 4 prevents dust from spreading outward. Frame 6 and scrap cart left hanger 8 are installed on the bottom surface of pedestal 5, left and right are symmetrical, play a supporting and fixing role to scrap cart 7, let scrap cart 7 be close to the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com