Dynamic pressure bearing device, method of manufacturing the same, and motor using the same

A technology for dynamic pressure bearings and bearing housings, applied in the direction of sliding contact bearings, bearings for rotational motion, rigid supports for bearing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention are described below.

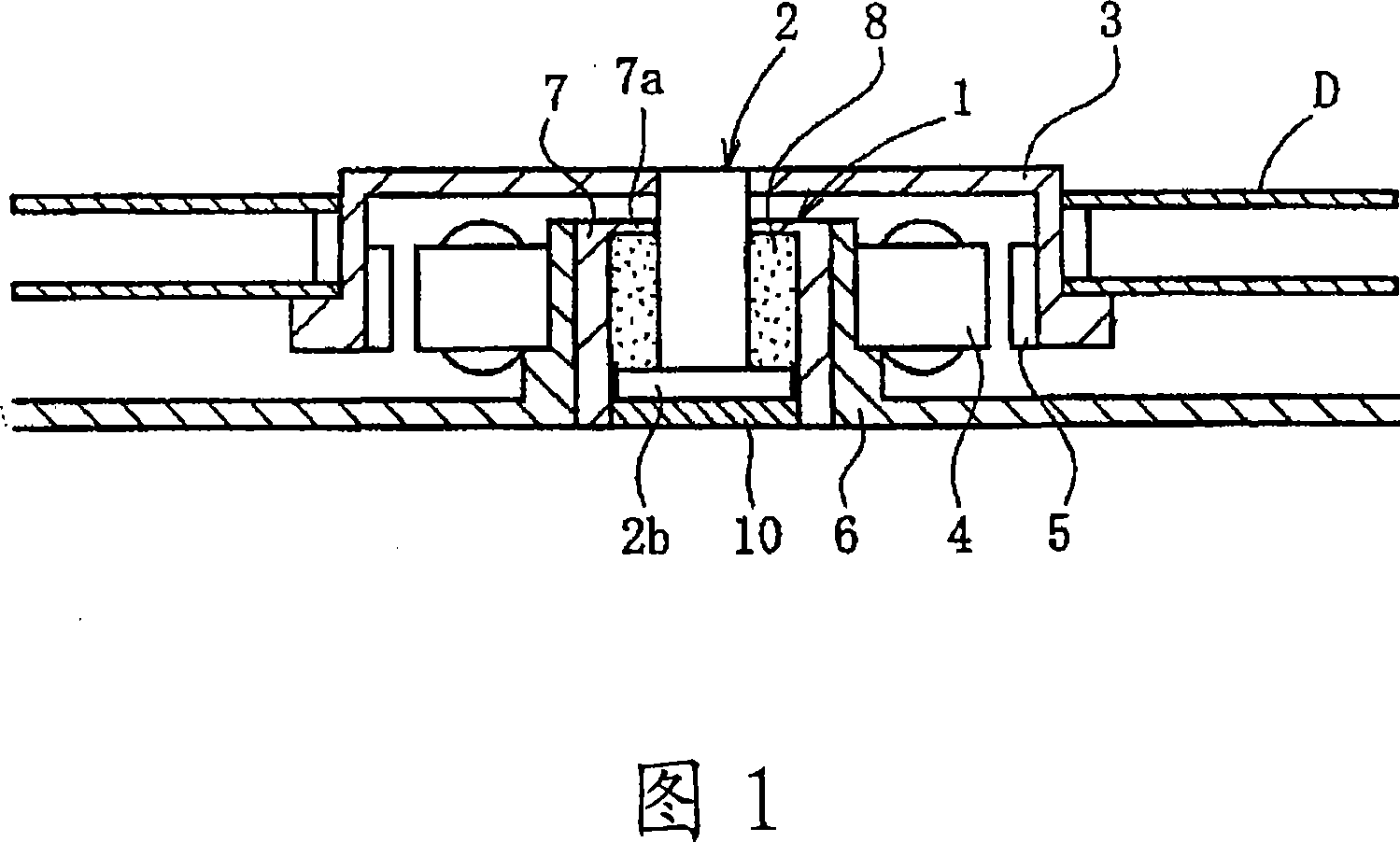

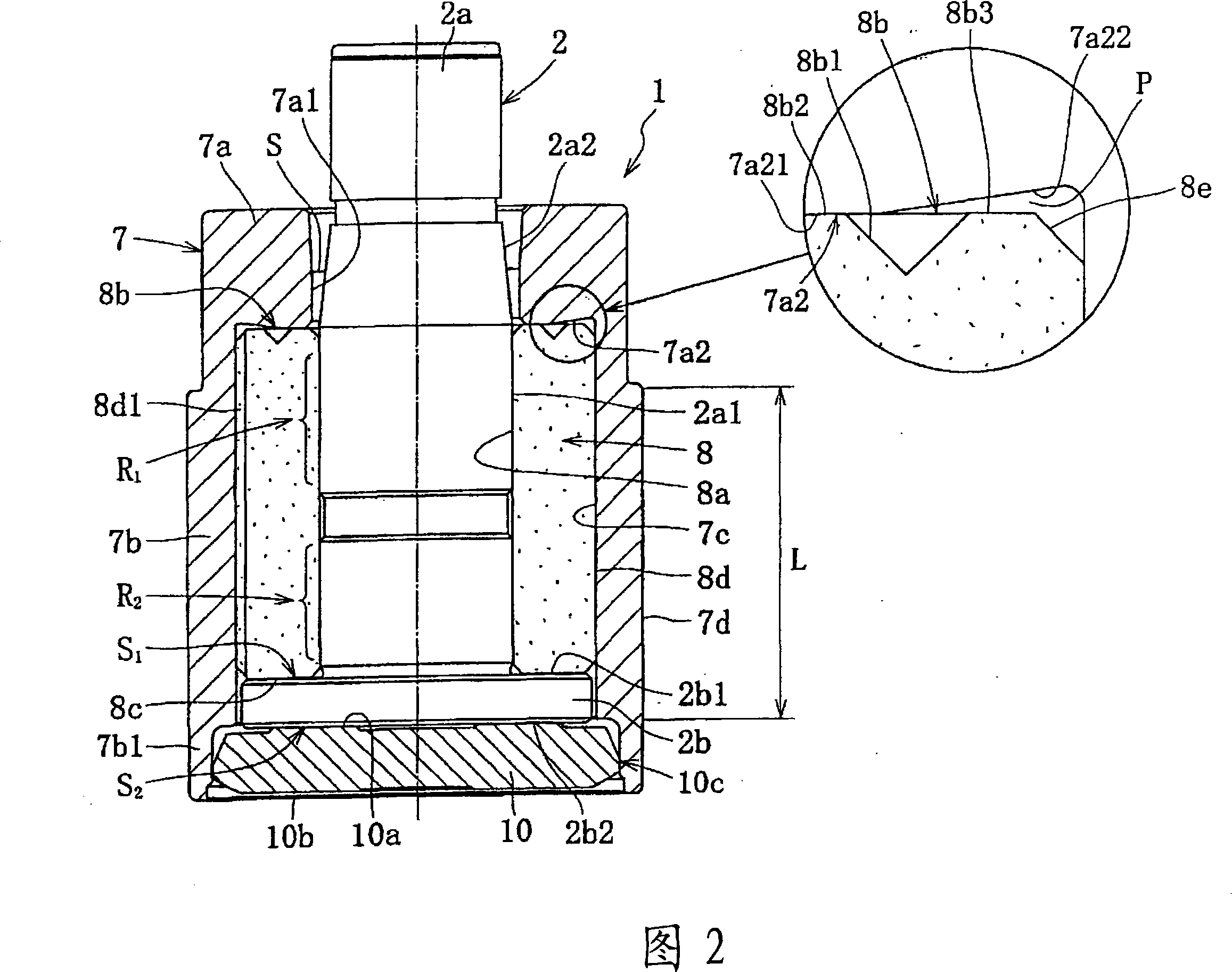

[0046] FIG. 1 shows an example of the structure of a spindle motor of an information processing apparatus equipped with a dynamic pressure bearing device 1 according to this embodiment. This spindle motor is used on a disk drive device such as an HDD, and includes: a disk hub 3 serving as a rotor, a dynamic pressure bearing device 1 for supporting the rotation of the disk hub 3, and a thrust member for holding the dynamic pressure bearing device 1. The frame 6 of the pressure bearing device 1, and the stator 4 and the rotor magnet 5 are arranged between the disk center 3 and the frame 6 and are opposed to each other with a predetermined gap provided therebetween. In this embodiment, the magnetic disk center 3 is mounted on the shaft member 2 of the dynamic pressure bearing device 1 . The stator 4 is attached to the outer circumference of the frame 6, the rotor magnet 5 is attached to the inner circumference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com