Electrophoresis coating method and whole set apparatus for pattern transfer of positive electrophoresis coating on printing board

An electrophoretic coating, electrophoretic coating technology, applied in the direction of electrolytic coating, electrophoretic plating, application of photosensitive materials, etc., can solve the problem that no solution is found, the graphic lines cannot meet the requirements of small and clear, and achieve fine circuit graphics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

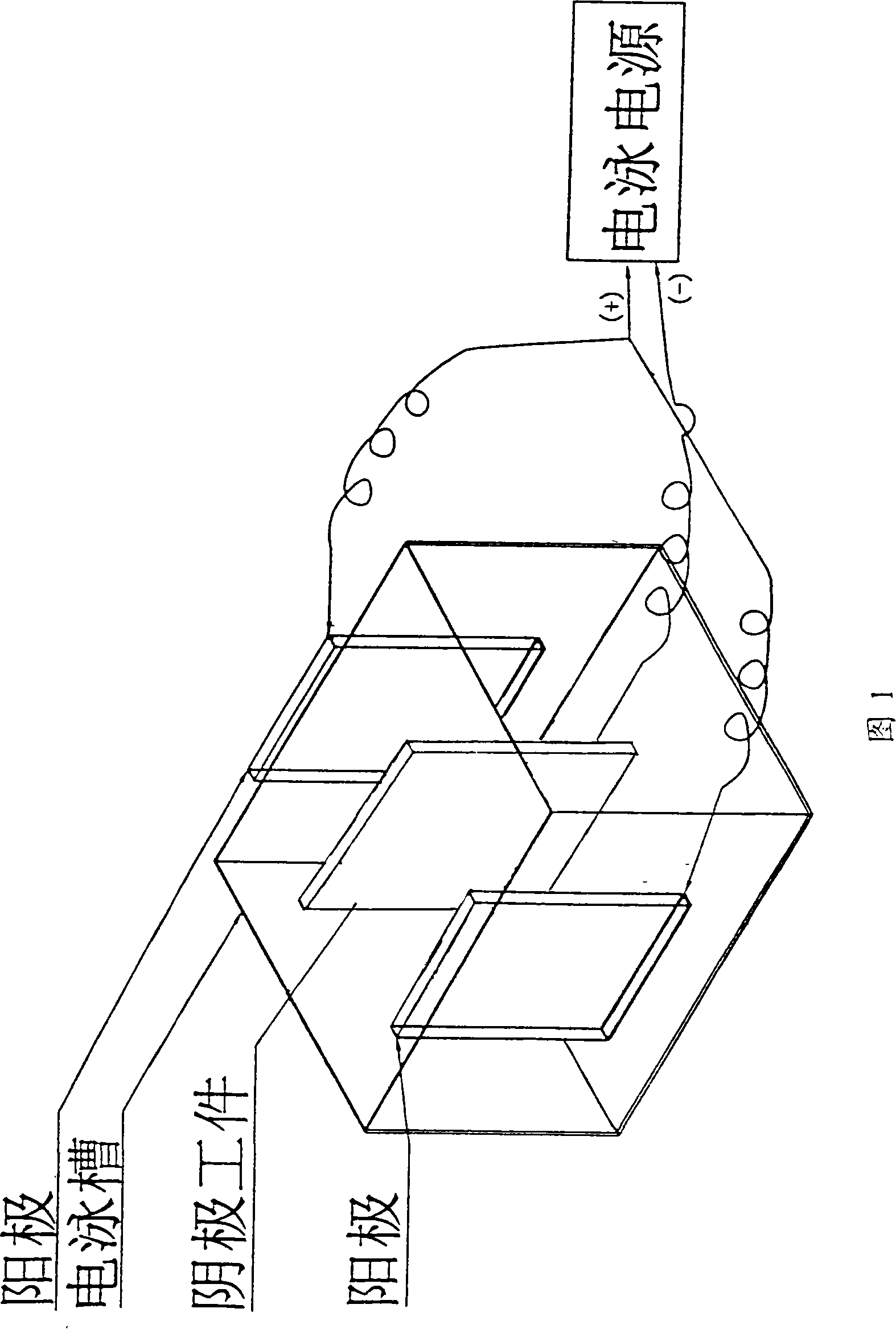

[0027] As shown in Figure 1, the present invention adopts cathodic electrophoresis process, specifically comprises the following steps:

[0028] (1) Connect the printed circuit board and the conductive device as the cathode, the conductive device is connected to the negative pole of the electrophoresis power supply, and the anode of the electrophoresis device is connected to the positive pole of the power supply as the anode system;

[0029] (2) Place the printed circuit board in an electrophoresis tank filled with an electrophoretic paint solution for electrophoresis.

[0030] (3) After electrophoresis, rinse off the floating paint on the surface of the printed circuit board;

[0031] (4) The printed circuit board is photosensitively treated by photocuring equipment, so that the electrophoretic paint film is leveled and formed;

[0032] (5) The electrophoretic positive electrophoretic paint film is processed to produce printed board graphics through exposure, development and...

Embodiment 2

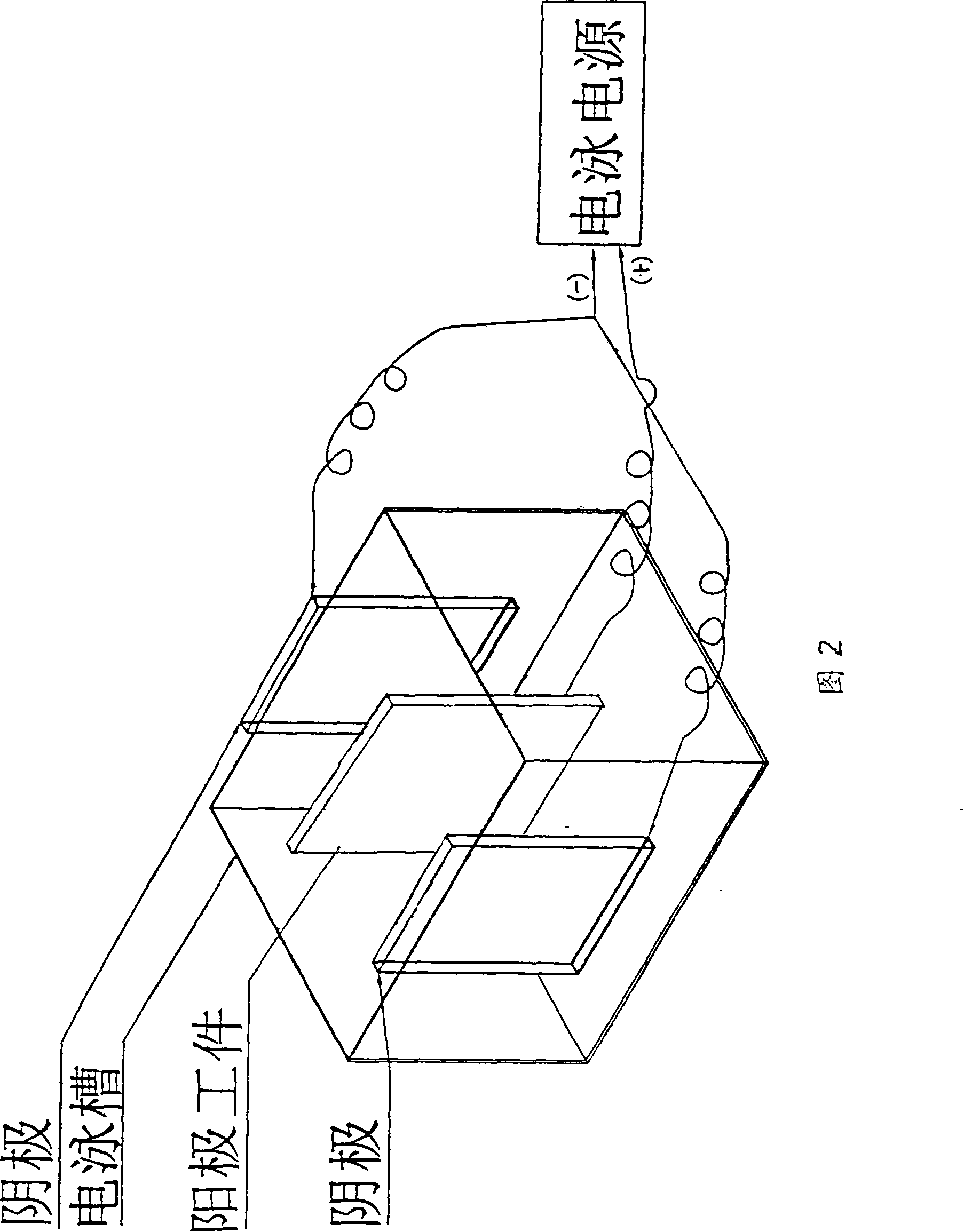

[0039] As shown in Figure 2, the present invention also can adopt anodic electrophoresis process, specifically comprises the following steps:

[0040] (1) Connect the printed circuit board and the conductive device as the anode system, the conductive device is connected to the positive pole of the electrophoresis power supply, and the cathode of the electrophoresis device is connected to the negative pole of the power supply as the cathode system;

[0041] Other steps and the equipment used are the same as in Example 1.

[0042] In the above two embodiments, the printed circuit board is a single-layer, double-layer or multi-layer printed circuit board; wherein the electrophoretic coating used in the electrophoresis process includes polybutadiene resin, phenolic resin, epoxy resin , acrylic or polyurethane resin; wherein the electrophoretic coating used in the electrophoretic process includes colorless transparent, matte colorless or colored coatings; wherein the electrophoreti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com