Outer sphenoid adjustment striking flake type fastener

A shrapnel, a new type of technology, applied in roads, rails, buildings, etc., can solve the problems of insufficient strength of shrapnel and pins, difficult installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

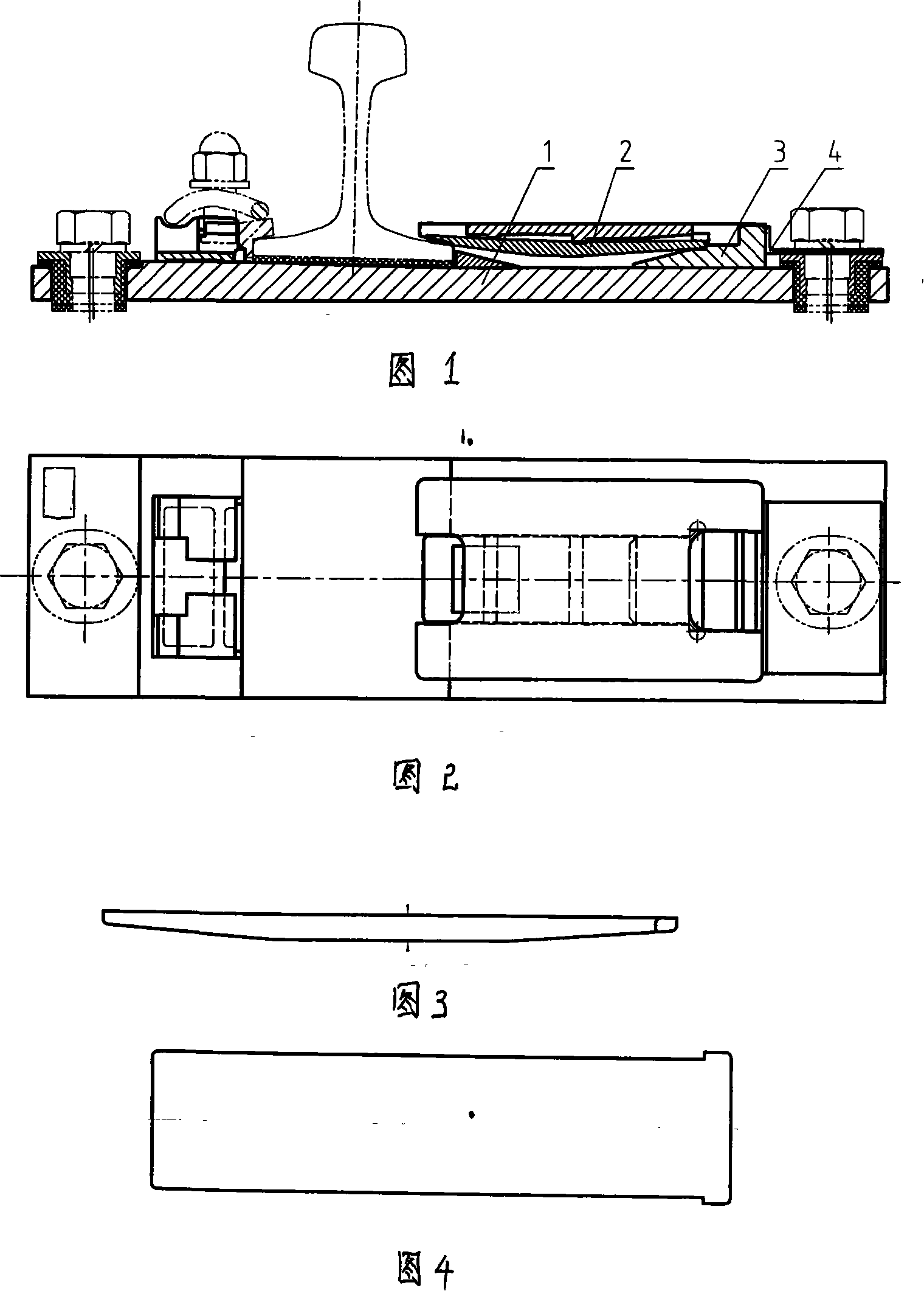

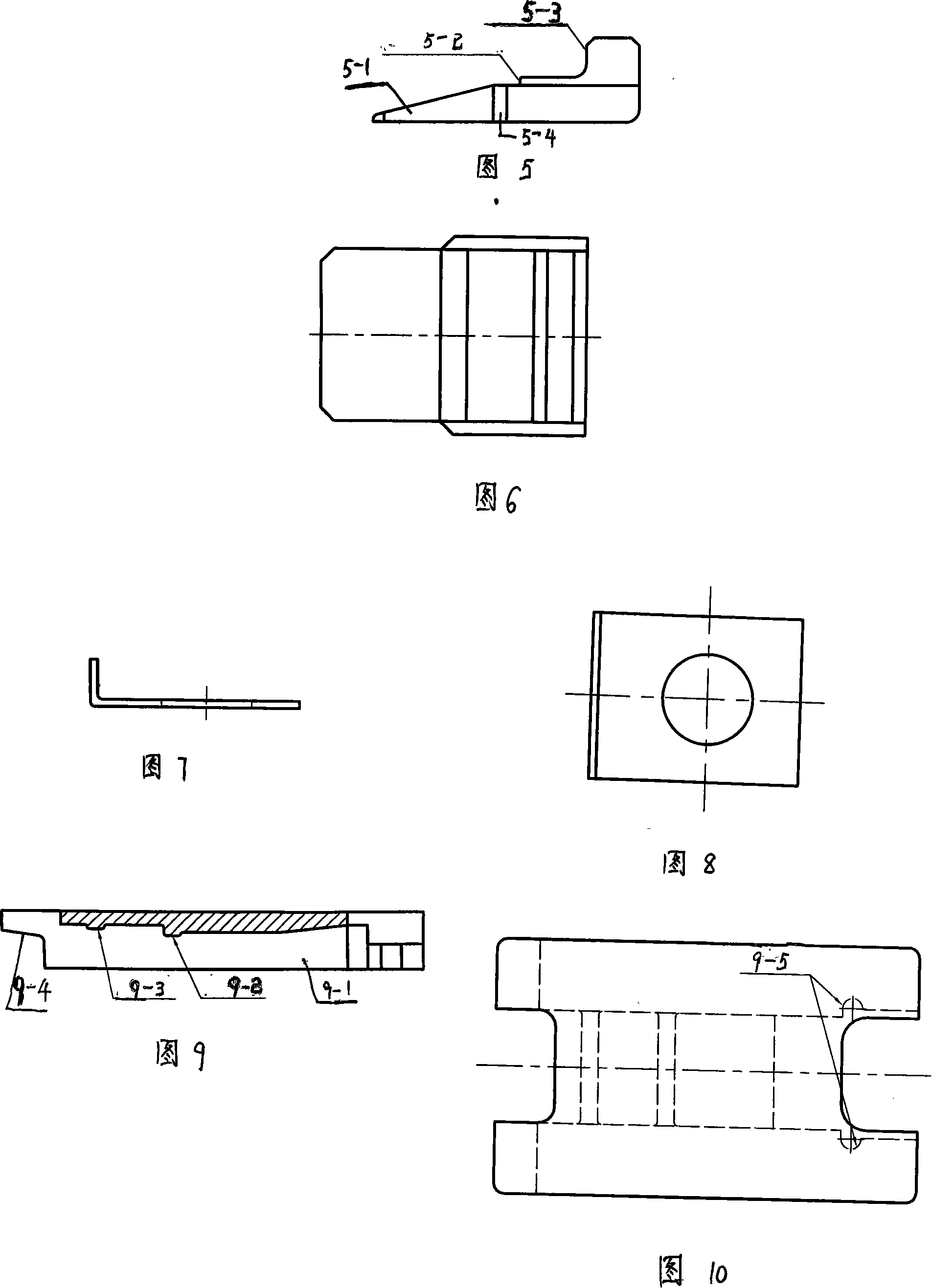

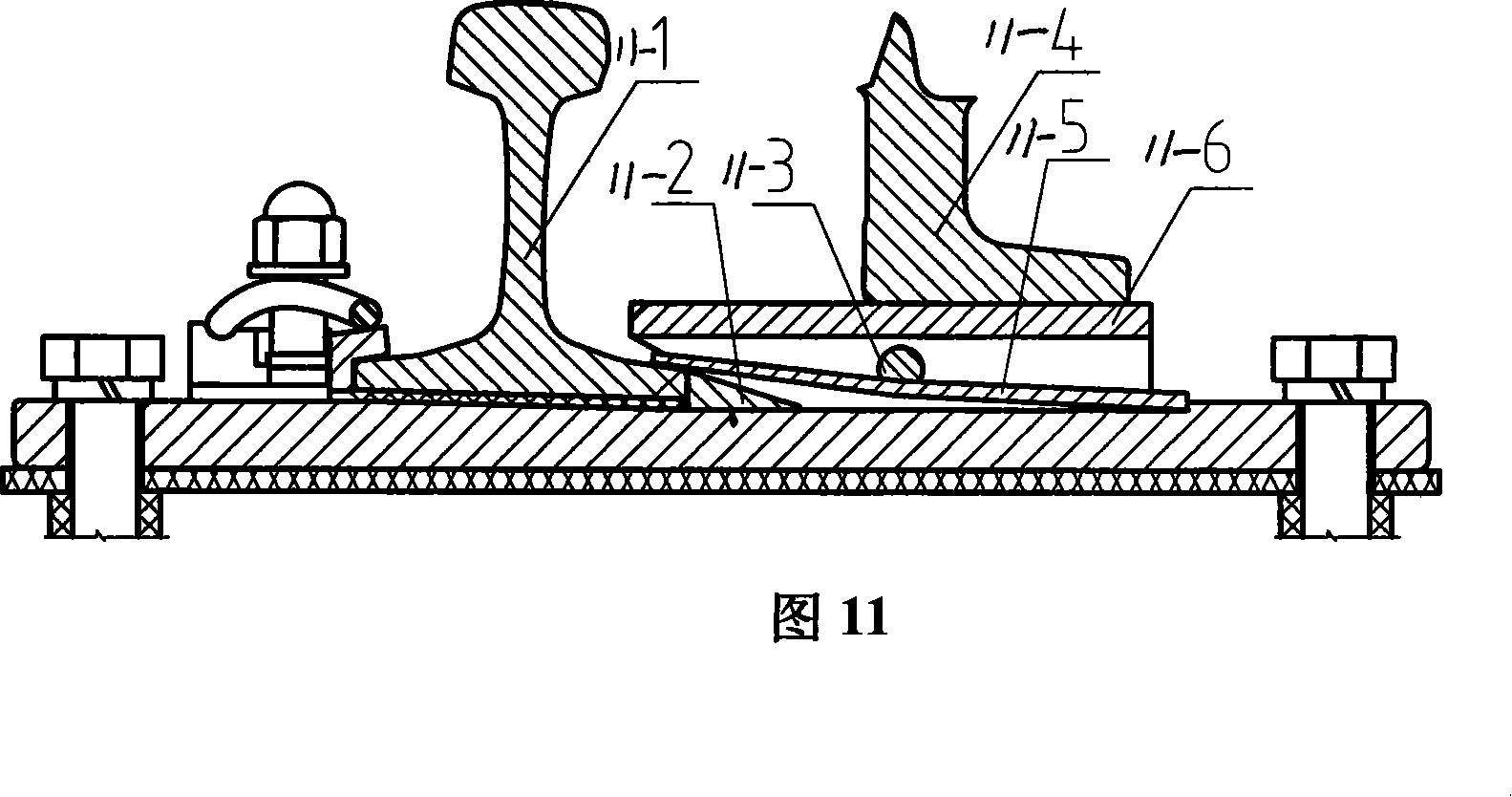

[0027] The design and working principle of the present invention is: the outer wedge-shaped adjustment of the new type of shrapnel type fastener is to buckle the front end of the shrapnel on the bottom of the basic rail, the rear end is raised with a wedge-shaped positioning block, and the supporting boss in the inner cavity of the table plate presses down the shrapnel, that is In the working state, the two ends of the shrapnel are upturned, and the middle is concave. The supporting boss in the middle and the positioning wedge at the rear end make the front end of the shrapnel generate a buckle force of 12KN.

[0028] From the perspective of the overall structure, the new type of shrapnel-type fastener for external wedge adjustment includes base plate 1, shrapnel 2, platen 5, and wedge-shaped positioning block 3. The card slot is fixed between the basic rail and the wedge-shaped positioning block 3; the inclined plane guide iron 7 is fixed on the bottom plate 1 close to the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com