Guide bar nondestructive technique after colliding for overground fire hydrant

A technology of fire hydrants and guide rods, applied in the direction of water outlet devices, flange connections, pipes/pipe joints/fittings, etc., can solve the problems of unsafe environment and waste of water resources, and achieve water conservation, ingenious ideas, and craftsmanship reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

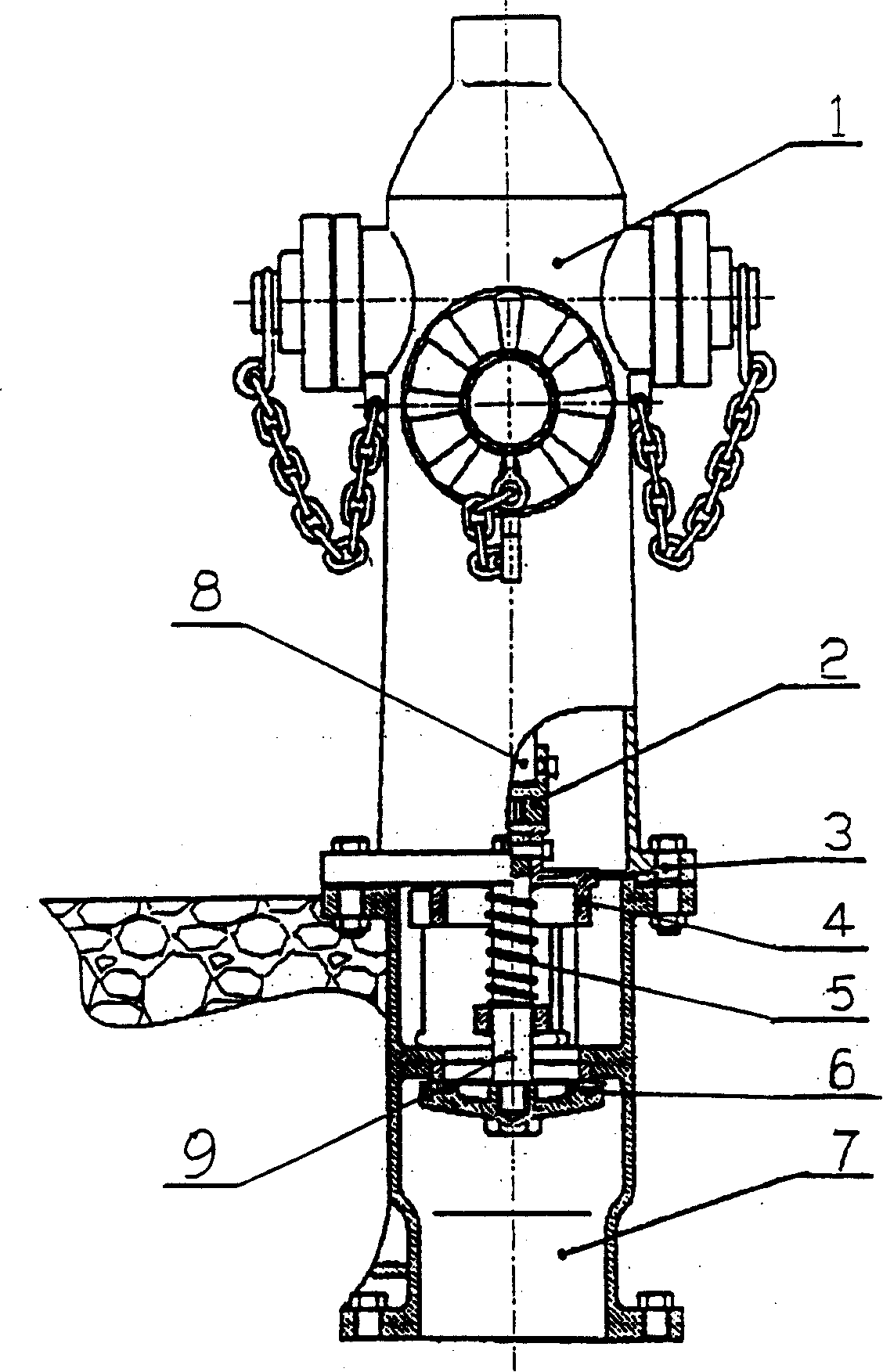

[0008] A non-destructive technique for a guide rod of an above-ground fire hydrant after collision, mainly comprising the following steps: A. dividing the guide rod in the hydrant body into two sections; B. connecting the two through a saw-tooth clutch. The structure of the ground fire hydrant manufactured by the present invention will be described in further detail below in conjunction with the accompanying drawings. Referring to the accompanying drawings, an above-ground fire hydrant with no damage to the guide rod after collision is mainly composed of a bolt body 1, a valve body 7 and a guide rod. The bolt body 1 and the valve body 7 are connected by safety bolts 3. Bar is divided into two sections 8,9, and is connected by saw-tooth clutch 2, is provided with valve ring 4 under saw-tooth clutch 2, is covered with spring 5 on guide rod 9, and the bottom of guide rod 9 is provided with valve plug 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com