Measuring method of image measuring instrument

A technology of image measuring instrument and measurement method, which is applied in the field of measurement and can solve the problems of reduced detection efficiency and poor adaptability to workpiece changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

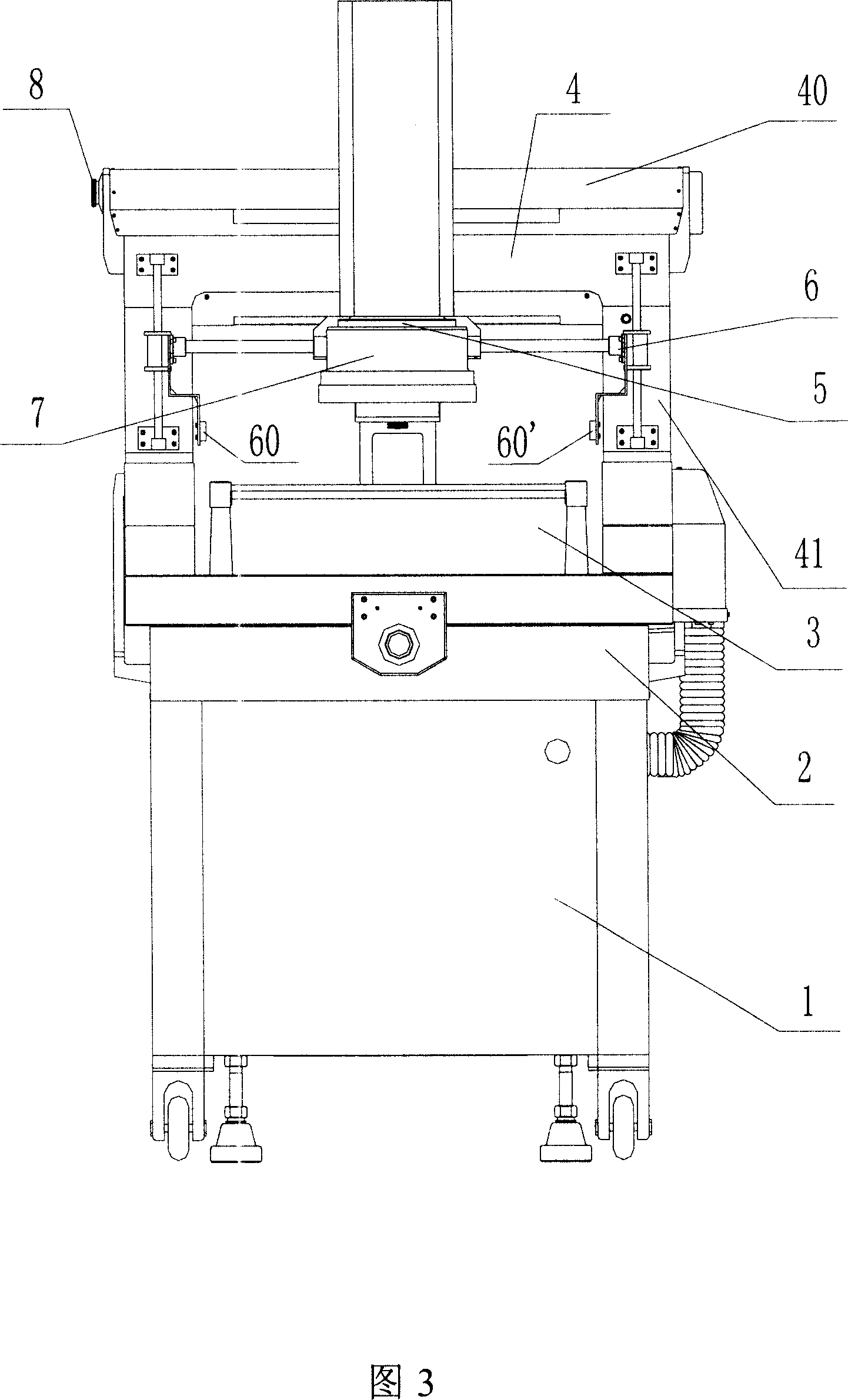

[0025] Please refer to Fig. 3, the image measuring instrument used in the measuring method of the image measuring instrument of the present invention includes a base 1, a base 2, a workbench 3, a gantry 4, X, Y, and Z transmission shafts, and is connected to the Z The motion system, lighting system, camera system and software control system composed of the Z-direction slider 5 on the transmission shaft system, the lighting system includes an upper light source and a bottom light source, and the camera system includes a camera lens and a video camera. The light source and camera lens are coaxially arranged in an upper light source lampshade 7 fixed on the Z-direction slider, the Z-direction transmission shaft is fixed on the gantry 4, and the X-direction transmission shaft 8 is arranged on the gantry 4 On the upper horizontal beam 40, the Y-direction transmission shaft system is arranged on the longitudinal beams of the gantry 4 on both sides of the workbench 3, the latter is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com