Electrostatic discharge test device and method

A technology of electrostatic discharge testing and discharge testing, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, and can solve problems such as inaccurate discharge test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now cooperate with accompanying drawing and reference numeral thereof to describe electrostatic discharge testing device of the present invention in detail, and enumerate preferred embodiment and explain as follows:

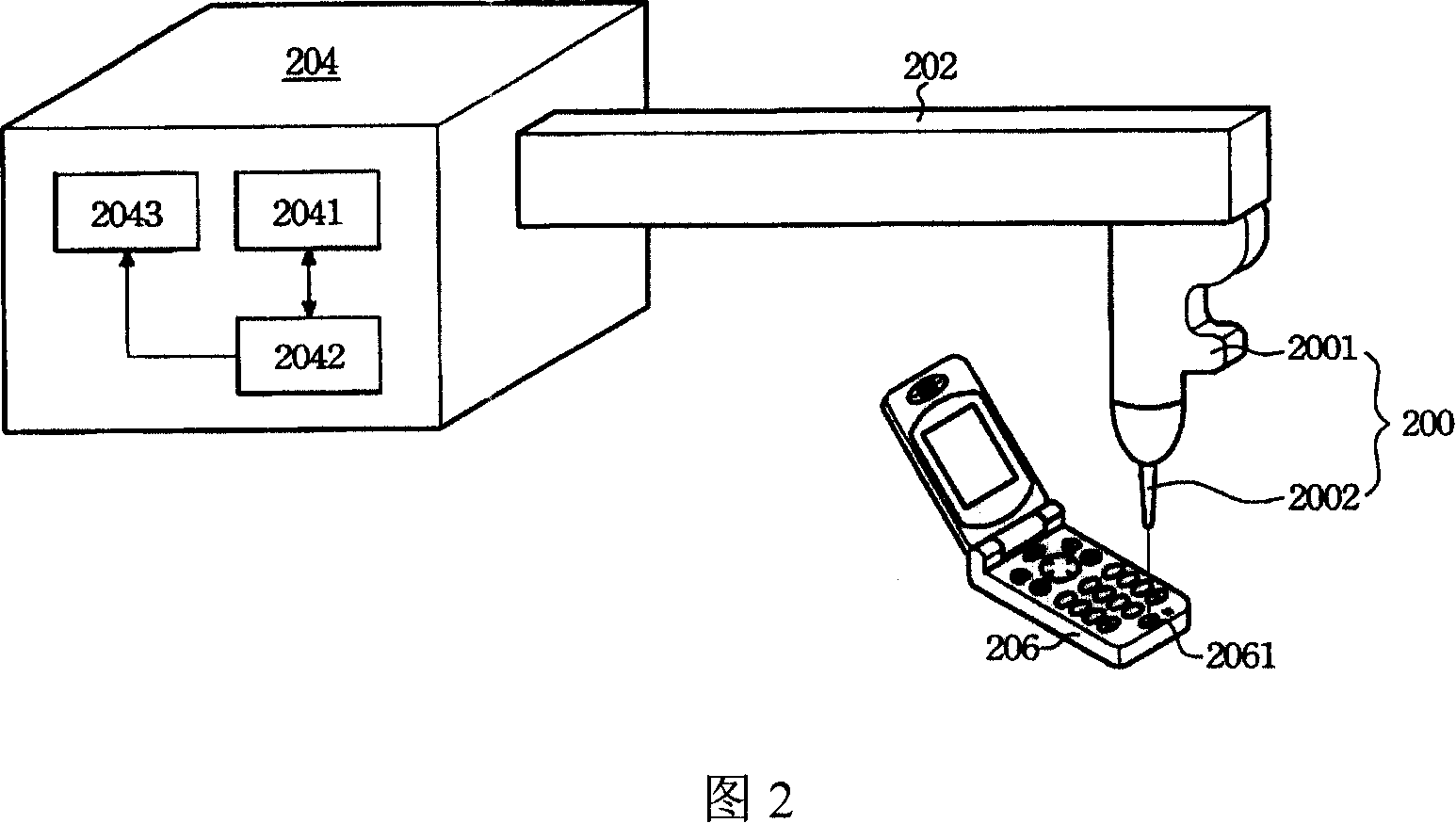

[0024] Please refer to FIG. 2 , which shows a schematic diagram of an electrostatic discharge testing device, which includes an electrostatic gun 200 , a control arm 202 and a control component 204 . The electrostatic gun 200 has a gun body 2001 and a muzzle 2002, and the muzzle 2002 is aimed at a component under test 206 to perform a discharge test. The control arm 202 is connected to the gun body 2001 , and the control component 204 is electrically connected to the control arm 202 , and controls the control arm 202 to perform a discharge test on the electrostatic gun 200 .

[0025] In general, the electrostatic gun 200 can be divided into contact discharge and air discharge. The discharge level can be divided into ±2kV, ±4kV, ±6kV or ±8kV, which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com