Considerable parallel type double-grade water purifying process purifier

A technology of water purification treatment and treatment equipment, which is applied in the direction of water/sewage treatment, water/sludge/sewage treatment, filtration circuit, etc., which can solve the problems of inconvenient use, increased production cost, large volume and weight, etc., and achieve The effect of large water supply, low manufacturing cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

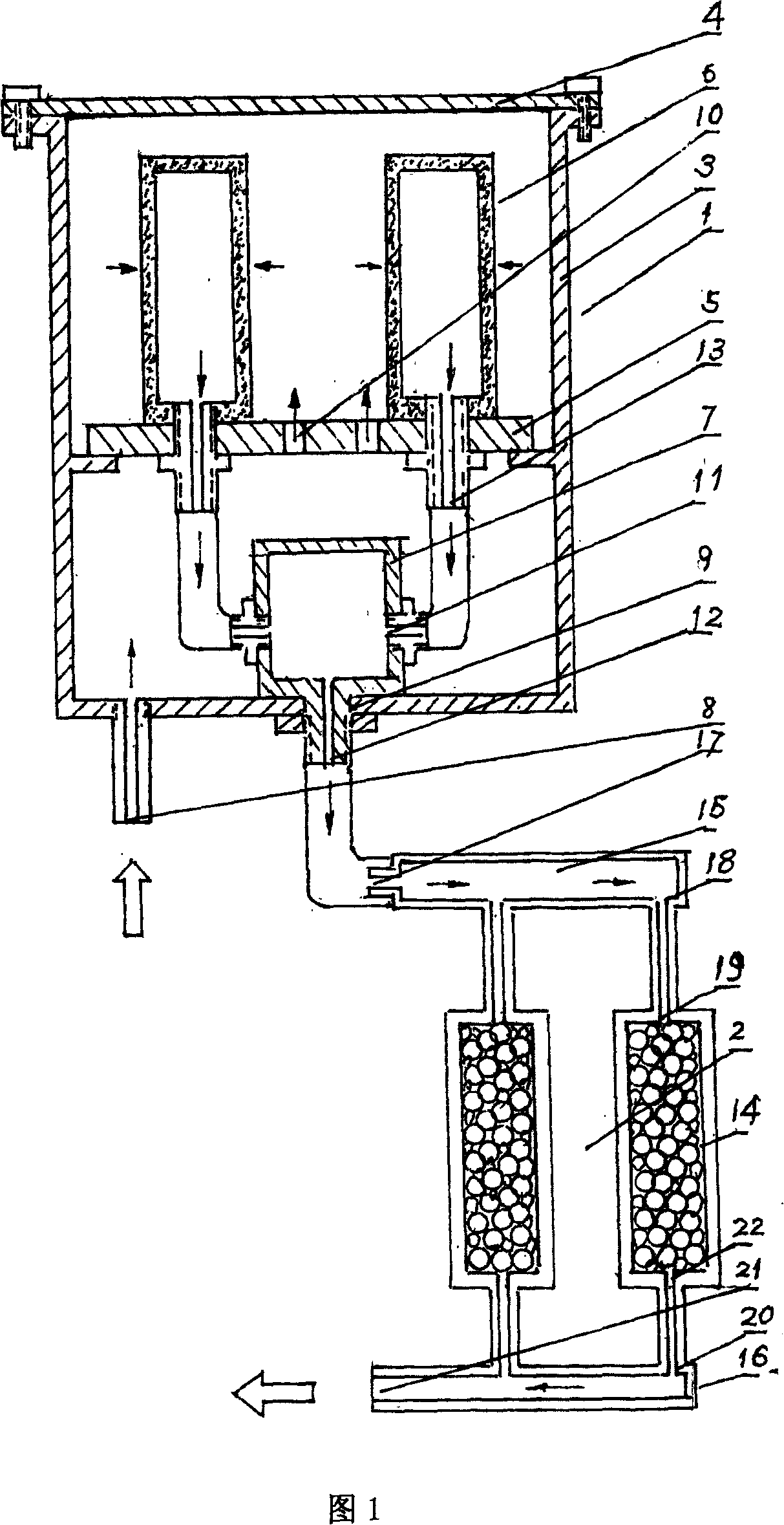

[0009] The specific implementation is as follows: it includes a primary water treatment device 1 and a secondary water treatment device 2; the primary water treatment device 1 includes a housing 3, an upper cover 4, a support plate 5, a ceramic filter element 6 and a ceramic filter element outlet pipe parallel joint 7 The housing 3 and the upper cover 4 are connected to form a closed container, the housing 3 has a general water inlet 8 and a joint installation hole 9, the support plate 5 is installed on the inner wall of the housing 3, and there are several water holes on the support plate 5 10, 15 ceramic filter elements 6 are installed on the support plate 5; the ceramic filter outlet pipe parallel joint 7 is installed in the housing 3, and there are 15 parallel joint water inlets 11 and one parallel joint water outlet on the ceramic filter outlet pipe parallel joint 7 12. The ceramic filter outlet pipe parallel joint 7 is installed on the joint installation hole 9 of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com