Method for producing 1, trimethylene glycol by feedback control of substrate concentration with intermediate metabolites

A substrate concentration, feedback control technology, applied in biochemical equipment and methods, biomass pretreatment, bioreactor/fermenter combination, etc., can solve the problems of affecting production control, low fermentation yield, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

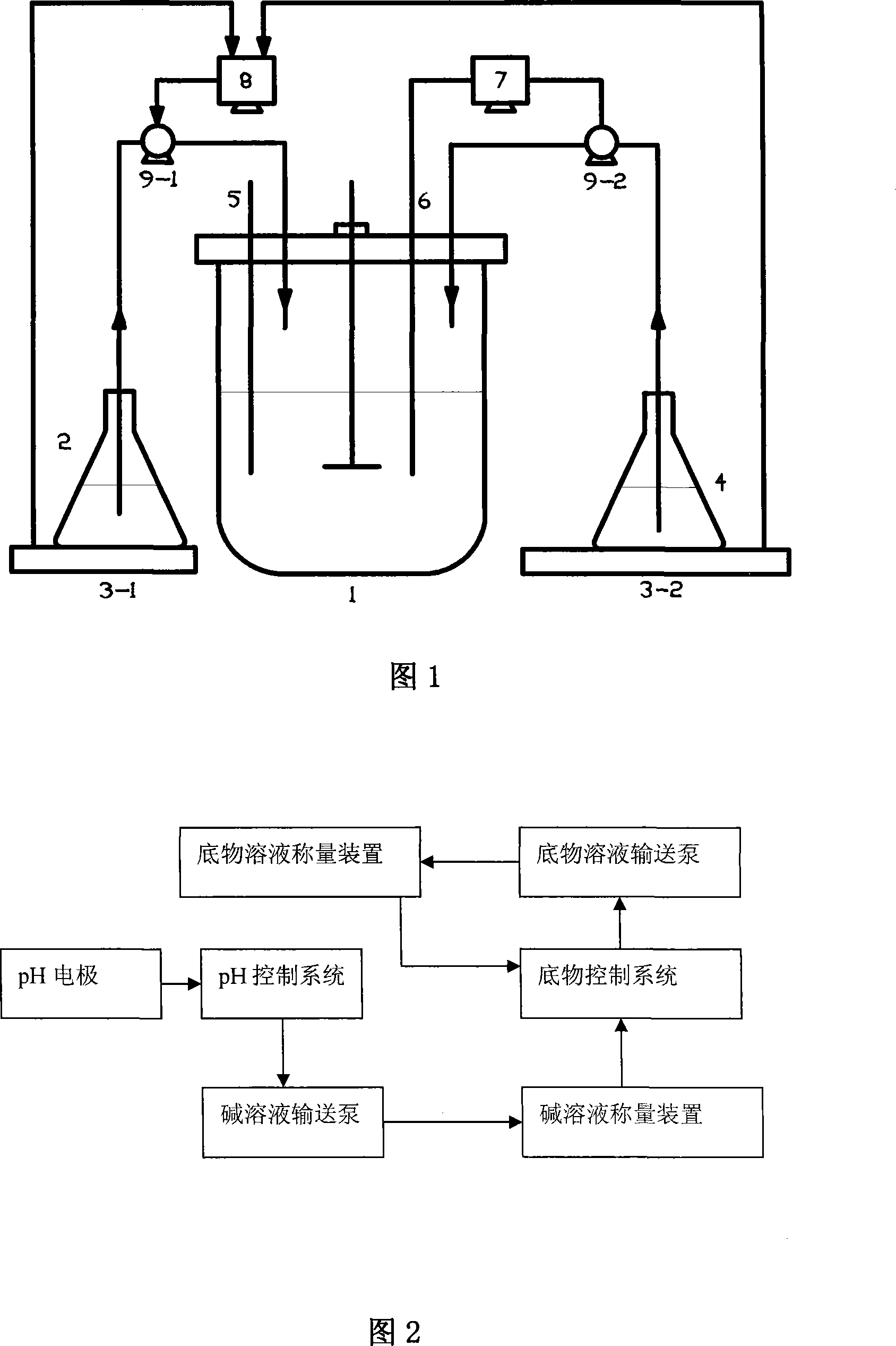

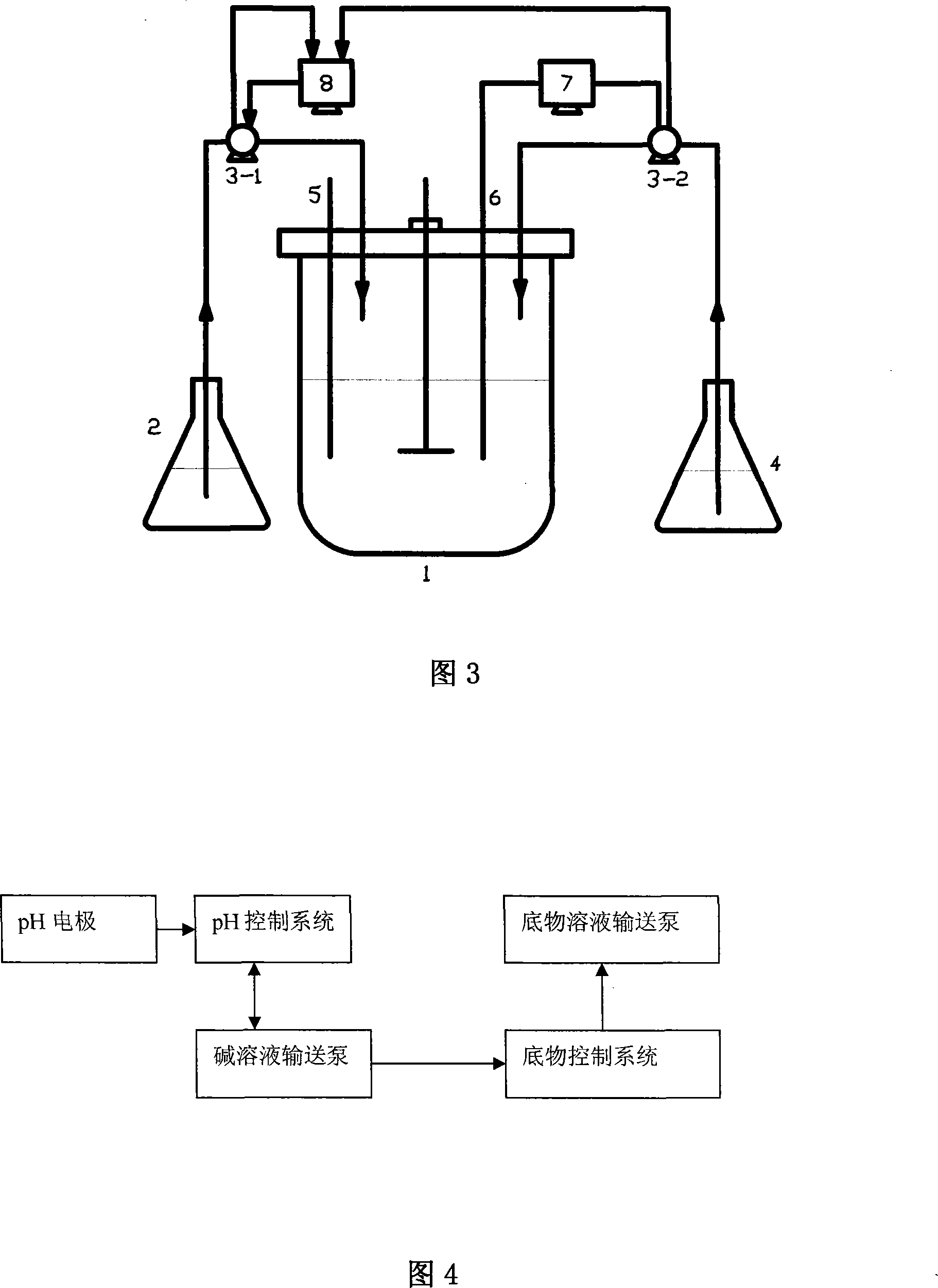

Method used

Image

Examples

preparation example Construction

[0056] 2. Preparation of seed solution:

[0057] Prepare the seed medium and sterilize it at 116°C for 25 minutes; insert the strain into the seed medium, and cultivate it at a suitable temperature for facultative anaerobic culture to the mid-logarithmic phase (about 12 hours after inoculation);

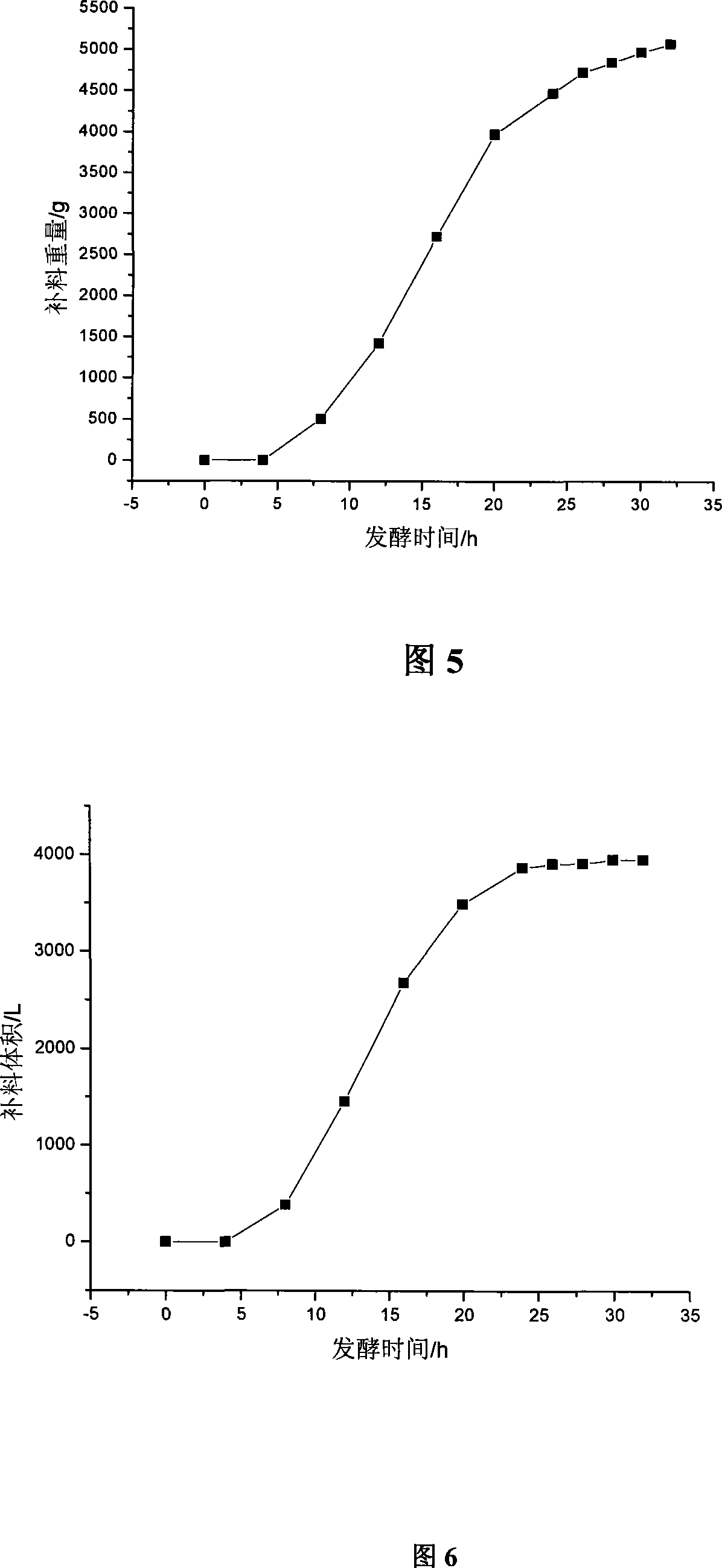

[0058] 3. Anaerobic fermentation: put the seed liquid prepared in step 2 into the fermentation medium sterilized at 116° C. for 25 minutes in a fermenter, control the appropriate temperature, stir, and not ventilate. During the fermentation process, as the substrate is converted into 1,3-propanediol and intermediate metabolites lactic acid and acetic acid, the pH of the fermentation broth decreases. When the pH of the fermentation broth drops below the set value, an alkaline solution is added to adjust the pH to rise To the set value, at the same time link the substrate feeding pump, add carbon source substrates (glucose, glycerol), and ferment for about 30 hours until the 1,3-propan...

Embodiment 1

[0060] Embodiment 1: (neutralizing agent base: the KOH of 4mol / L, starting substrate: glucose 8g / L, glycerol 10g / L, inoculum size: 5%, pH setting value: 7.0, fermentation temperature: 37 ℃, The added substrate in the feed solution is a mixture of glycerol, glucose and water, wherein the concentration of glycerol is 600g / L, and the concentration of glucose is 75g / L. The pre-control constant glycerol concentration is 10±5g / L, and the feedback control means: manual)

[0061] Material:

[0062] Microbial strains: Klebsiella pneumoniae, CGMCC No.1.1526 Medium:

[0063] 1) Inclined solid medium: glucose 8g / L, glycerol 10g / L, yeast powder 3g / L, K 2 HPO 4 ·3H 2 O3.4g / L, KH 2 PO 4 1.3g / L, (NH 4 ) 2 SO 4 4g / L, MgSO 4 0.24g / L, CaCO 3 0.5g / L, fumaric acid 25mg / L, agar 15g / L.

[0064] 2) Seed medium: glucose 8g / L, glycerol 10g / L, yeast powder 3g / L, K 2 HPO 4 ·3H 2 O3.4g / L, KH 2 PO 4 1.3g / L, (NH 4 ) 2 SO 4 4g / L, MgSO 4 0.24g / L, CaCO 3 0.5g / L, fumaric acid 25mg / L.

[00...

Embodiment 2

[0086] Material:

[0087] Microbial strains: Klebsiella pneumoniae, CGMCC No.1.1639

[0088] Neutralizing agent: the mixture of potassium hydroxide and ammoniacal liquor, wherein, potassium hydroxide is 4mol / L, and ammoniacal liquor (17%) consumption is 85.72g / L (as NH 3 The meter concentration is 25%-28%).

[0089] Supplementary substrate: a mixture of glycerol, glucose and water, wherein the concentration of glycerol is 600g / L, and the concentration of glucose is 75g / L.

[0090] Culture medium: basically the same as in Example 1, the air ventilation rate is controlled at 0.6L / (L·min), wherein the glucose is 5g / L, and the glycerol is 20g / L.

[0091] In this system, A=0.6849.

[0092] method:

[0093] 1, prepare seed: same as embodiment 1

[0094] 2. Fed-batch fermentation culture:

[0095] 1) Put 2 L of fermentation medium into a 5L fermentation tank, inoculate the secondary seed liquid after sterilization, the inoculation amount is 20%, install temperature electrodes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com