Coil locating structure of electronic expansion valve

A technology of electronic expansion valve and valve body, which is applied in the direction of valve operation/release device, valve details, valve device, etc., which can solve problems such as product failure, aging of encapsulation layer, and influence on coil insulation performance, so as to ensure normal operation , the effect of resisting high-frequency impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

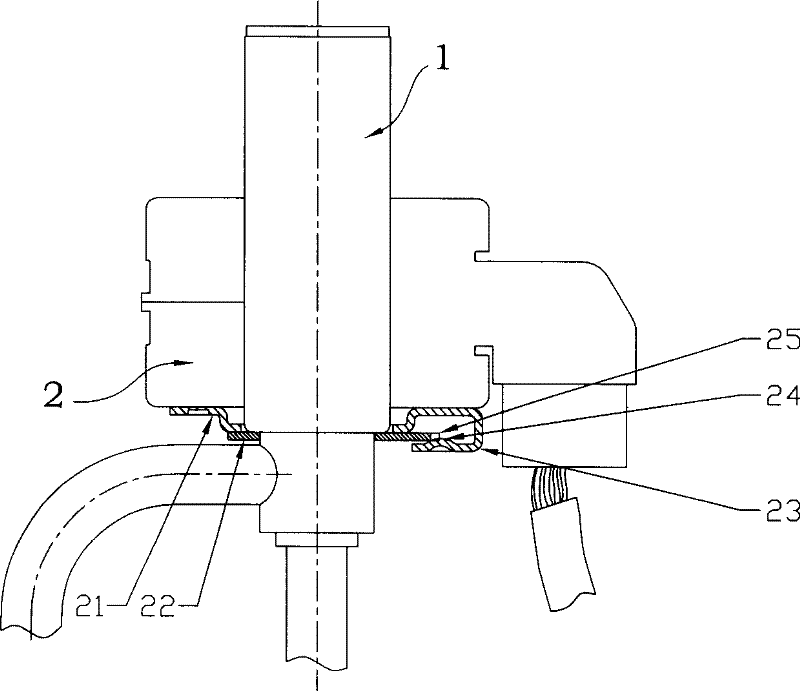

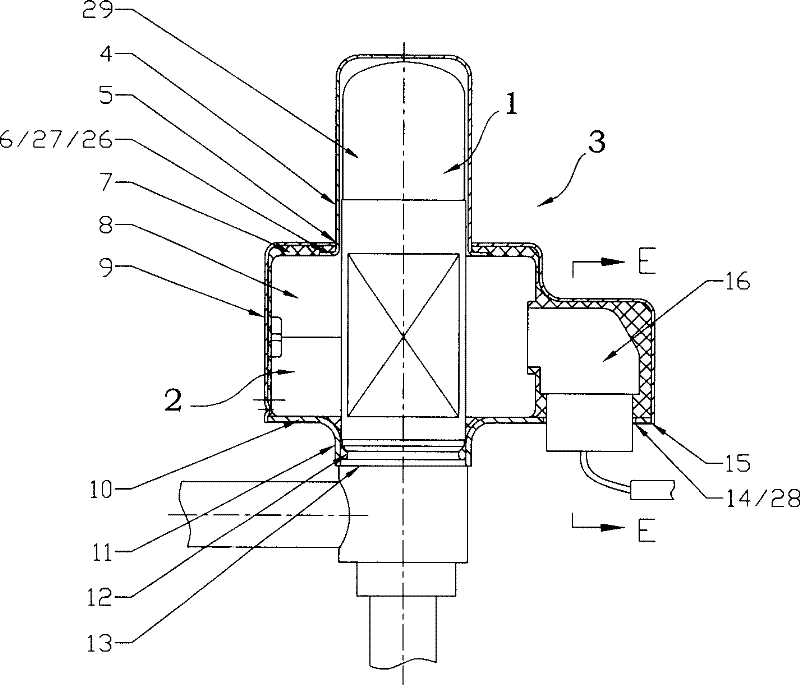

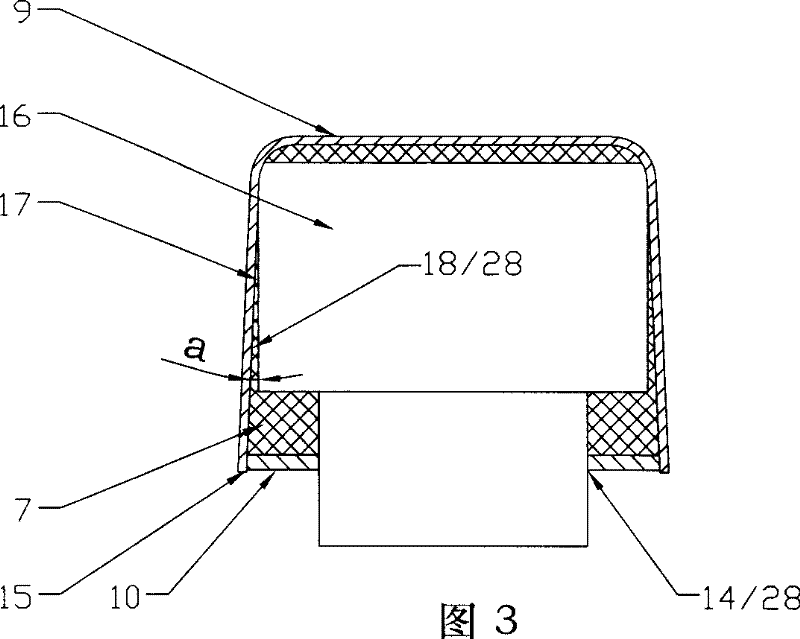

[0028] Such as figure 2 The electronic expansion valve shown to realize the positioning of the coil on the valve body includes a valve body 1 and a coil 2. The coil 2 has a winding part 8 and a socket part 16. There is an axial through hole 5 in the center of the winding part 8. The axial The through hole 5 is sleeved on the valve body 1, and a positioning member is provided between the coil 2 and the valve body 1, the details are:

[0029] The positioning member includes a bottom plate 10 and an outer cover 3;

[0030] The bottom plate 10 is fixed on the valve body 1 and supports the coil 2;

[0031] The outer cover 3 covers the outside of the coil 2 and has an axial positioning portion 26 corresponding to the bottom plate 10;

[0032] The outer cover 3 is fixedly connected to the base plate 10, and the axial positioning portion 26 presses the coil 2 on the base plate;

[0033] On the bottom plate 10 or the outer cover 3, a circumferential positioning part 28 is provided ...

Embodiment 2

[0041] Such as Figure 4 The electronic expansion valve that realizes the positioning of the coil on the valve body is illustrated on the basis of the structure of the first embodiment, and the differences between it and the first embodiment are explained, and the similarities will not be repeated:

[0042] The pressing part 27 is an outer flange 6 arranged at the lower end of the closing cap 4, the outer flange 6 is located on the lower side of the axial through hole 5 and is pressed on the upper end of the coil by the cover wall at the axial through hole 5, No filler is filled in the space between the housing 3 and the coil 2 .

Embodiment 3

[0044] Such as Figure 5 The electronic expansion valve that realizes the positioning of the coil on the valve body is illustrated on the basis of the structure of the first embodiment, and the differences between it and the first embodiment are explained, and the similarities will not be repeated:

[0045] The outer cover 3 includes a main part 9 corresponding to the coil 2 and a closing cap 4 extending from the main part to cover the protruding section 29. The pressing part 27 is a plane 20 on which the main part 9 is pressed on the upper end of the coil 2. Between the outer cover 3 and the The spaces between the coils 2 are not filled with fillers.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap