Method and control device for the targeted reaction in the event of contact between a machine element pertaining to a machine and an object

A technology of machine components and control devices, applied in computer control, general control systems, program control, etc., can solve problems such as unidentifiable errors, no components taken into account, wrong visual judgments, etc., and achieve the effect of simple collision recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

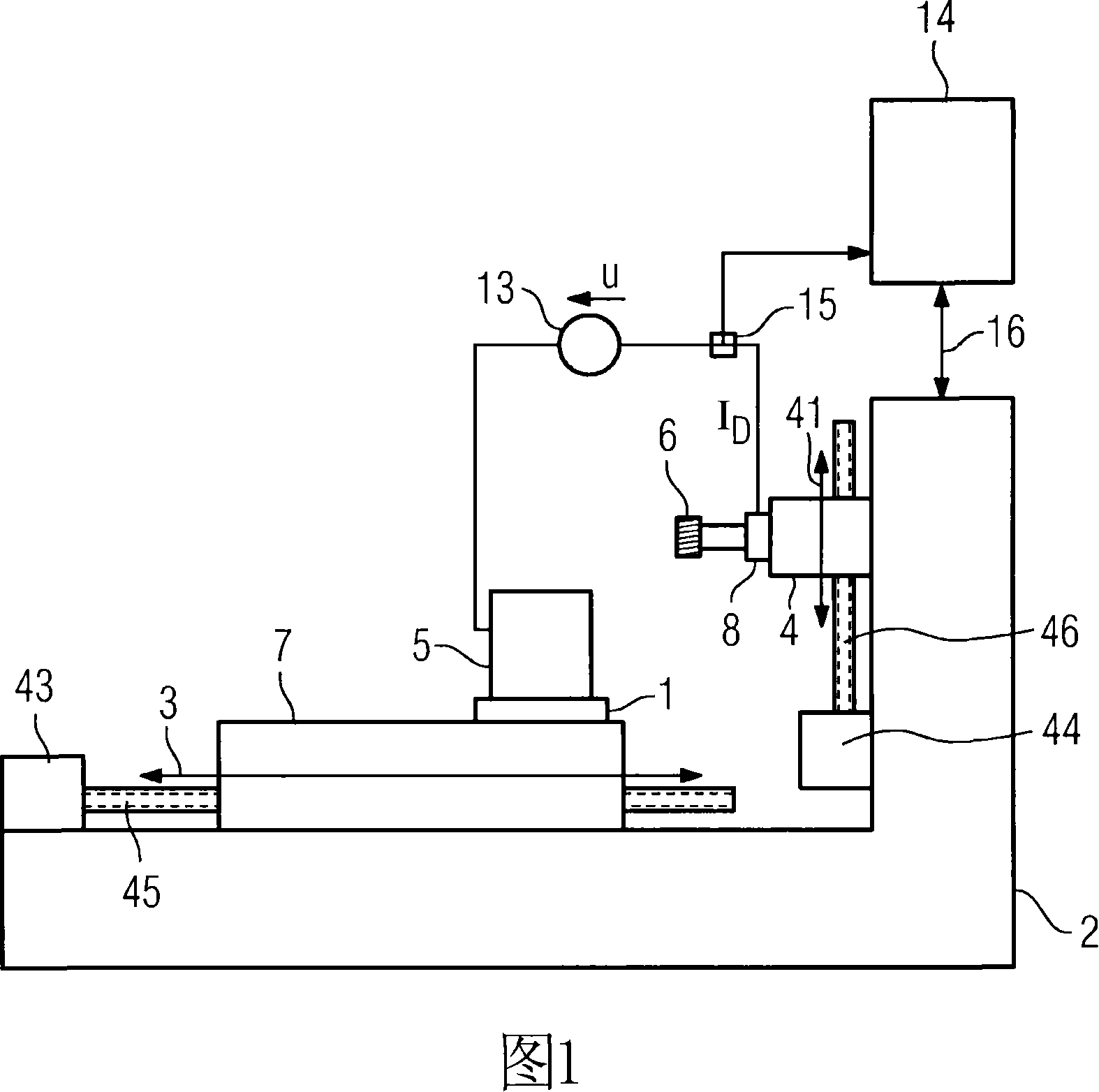

[0042]FIG. 1 shows an exemplary embodiment of a machine tool in schematic form. The machine tool shown has a machine base 2 , a tool carriage 7 and a drive device 4 , which drives a tool 6 via a spindle 8 . Furthermore, the machine tool shown has a control device 14 (for example a numerical control device) for controlling it. The control device 14 controls the machine tool via a connection 16 . The figures show, by way of example, a machine tool with two machine axes. Therefore, the carriage 7 can move in the direction shown by the double-headed arrow 3 (horizontal shaft) in the horizontal direction under the drive of a driving device 43 of the horizontal shaft, and the driving device 4 that drives the main shaft to rotate can take the main shaft 8 and cutter 6 are driven by a driving device 44 of the vertical axis to move in the vertical direction in the direction shown by the double-headed arrow 41 (vertical axis). To generate a corresponding linear movement, the drives 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com