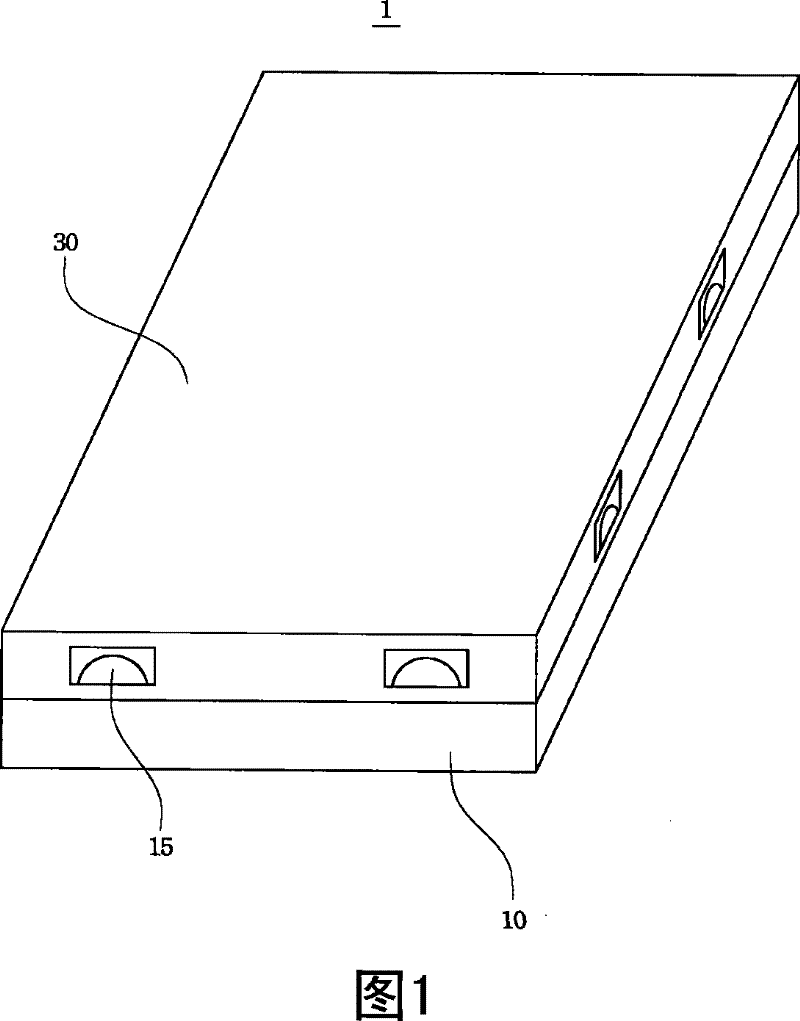

Manufacturing method of back board of backlight module

A manufacturing method and backlight module technology, applied in the fields of optics, nonlinear optics, components of lighting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

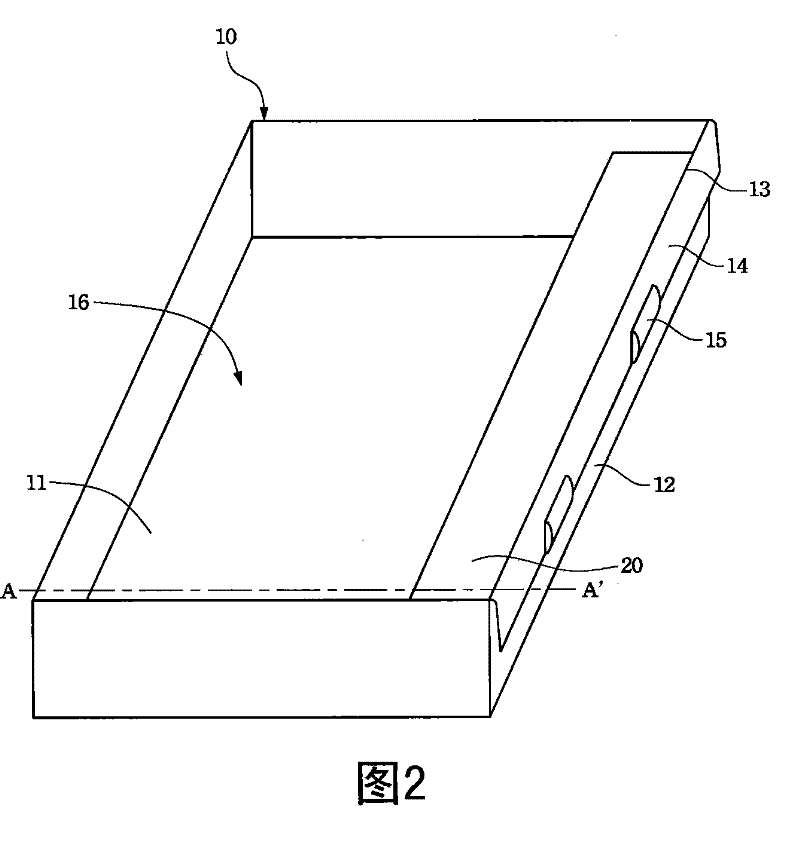

Embodiment Construction

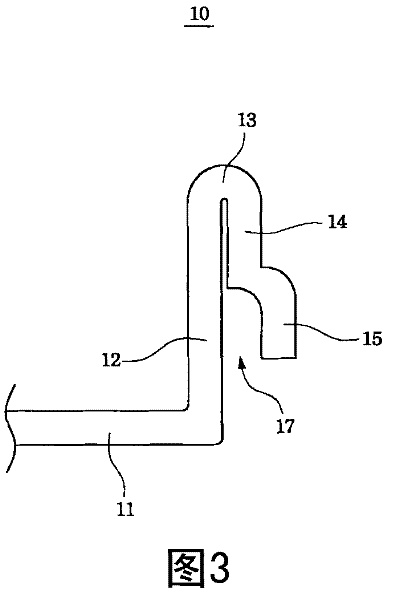

[0032] image 3 for figure 1 A side view of the backplane 10. like image 3 As shown, the engaging portion 15 can extend away from the inner portion 12, that is, the engaging portion 15 can protrude outward to engage figure 1 The upper frame 30 and the backplane 10. more specifically, image 3 The engaging portion 15 can have a groove 17 on its side facing away from the curved portion 13, so as to be manufactured by stamping technology. It should be understood that the above-mentioned shape of the engaging portion 15 is for illustration only, and is not intended to limit the present invention. As long as the upper frame and the back panel can be engaged, the engaging portion can also have other appropriate shapes.

[0033] for example, Figure 4 Although the engaging portion 15 protrudes from the surface of the reflex portion 14 and also has a groove 17, it is different from image 3 Yes, Figure 4 The bottom of the engaging portion 15 is folded toward the inner port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com