A hinged type self-discharging automobile chassis

A dump truck, articulated technology, applied in the direction of motor vehicles, tractor-trailer combination, transportation and packaging, etc., can solve the problems of limiting the maneuverability of dump trucks, high manufacturing costs of oil and gas springs, troublesome maintenance, etc., to achieve structural Simple, good maneuverability, and the effect of improving maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

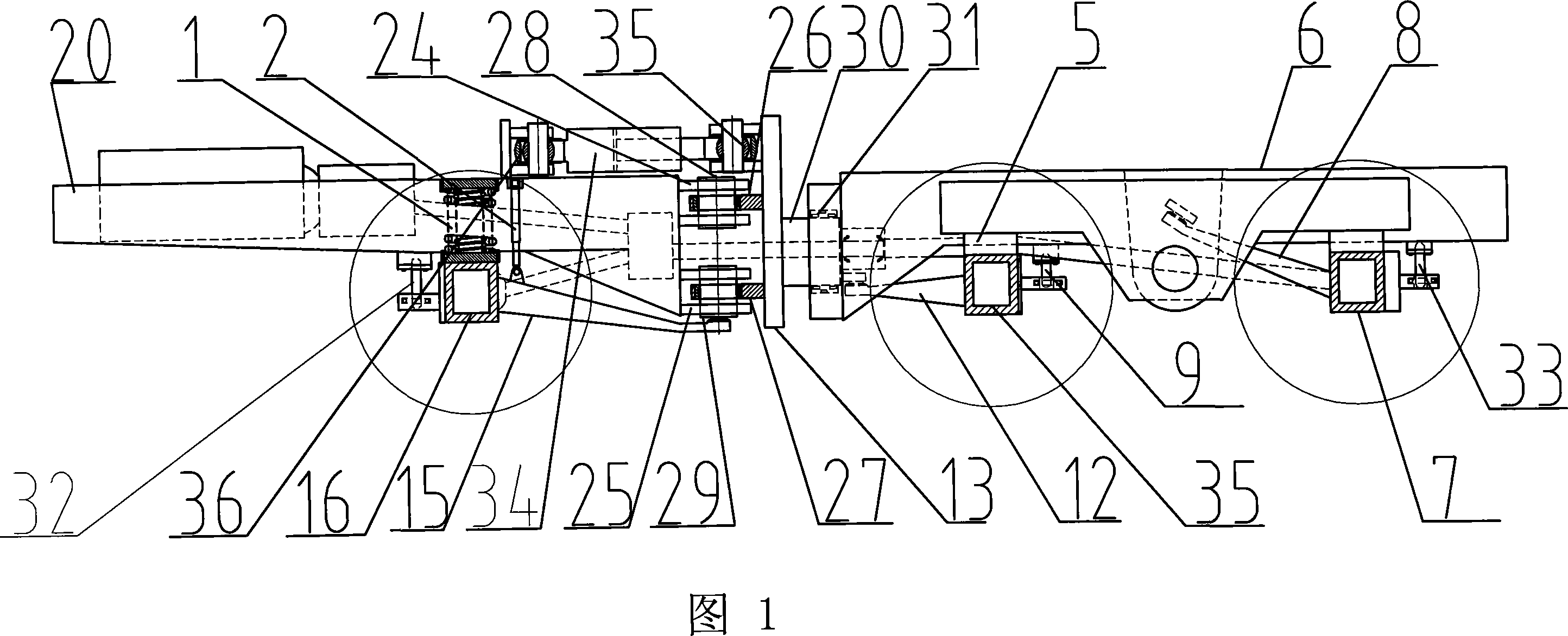

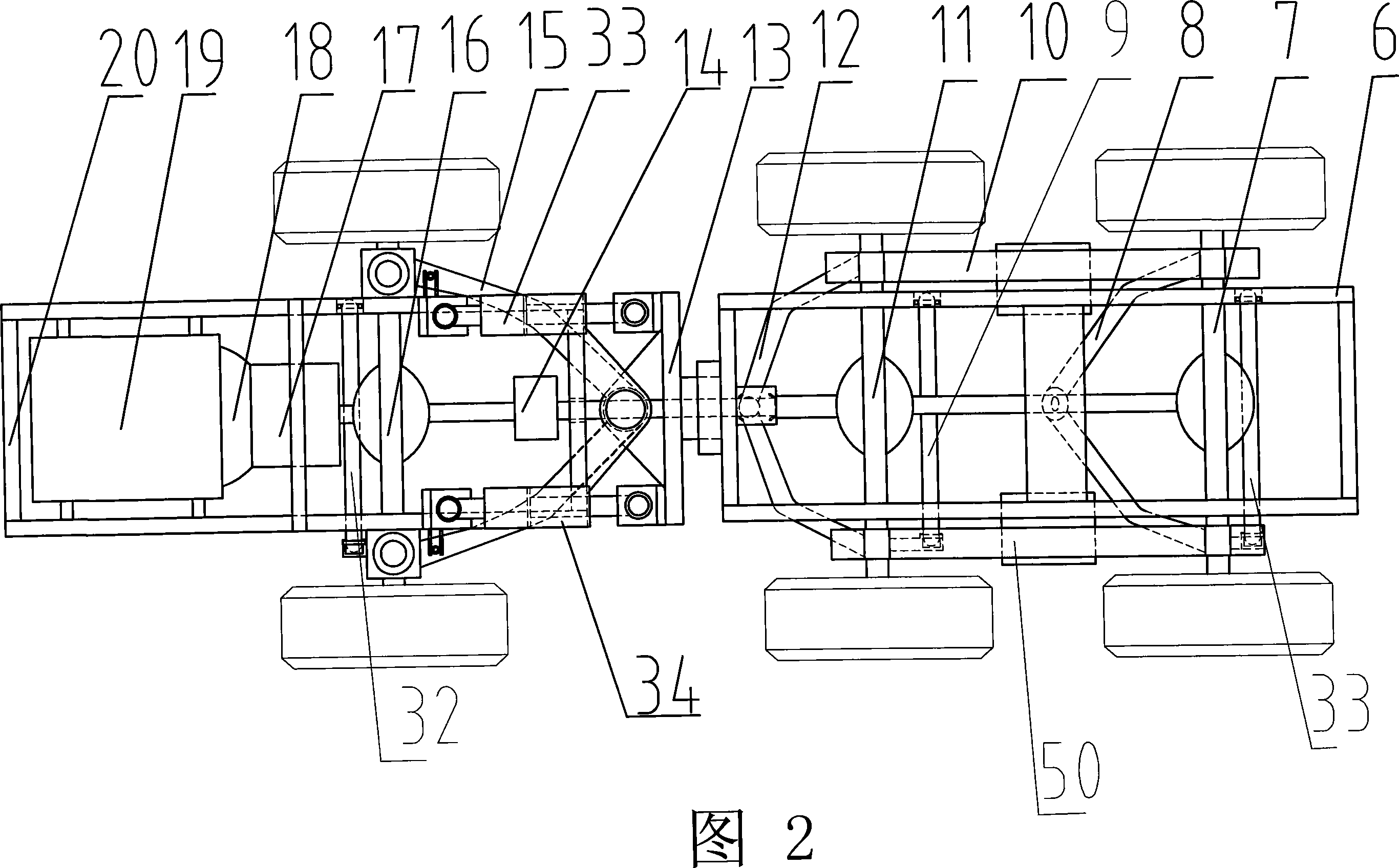

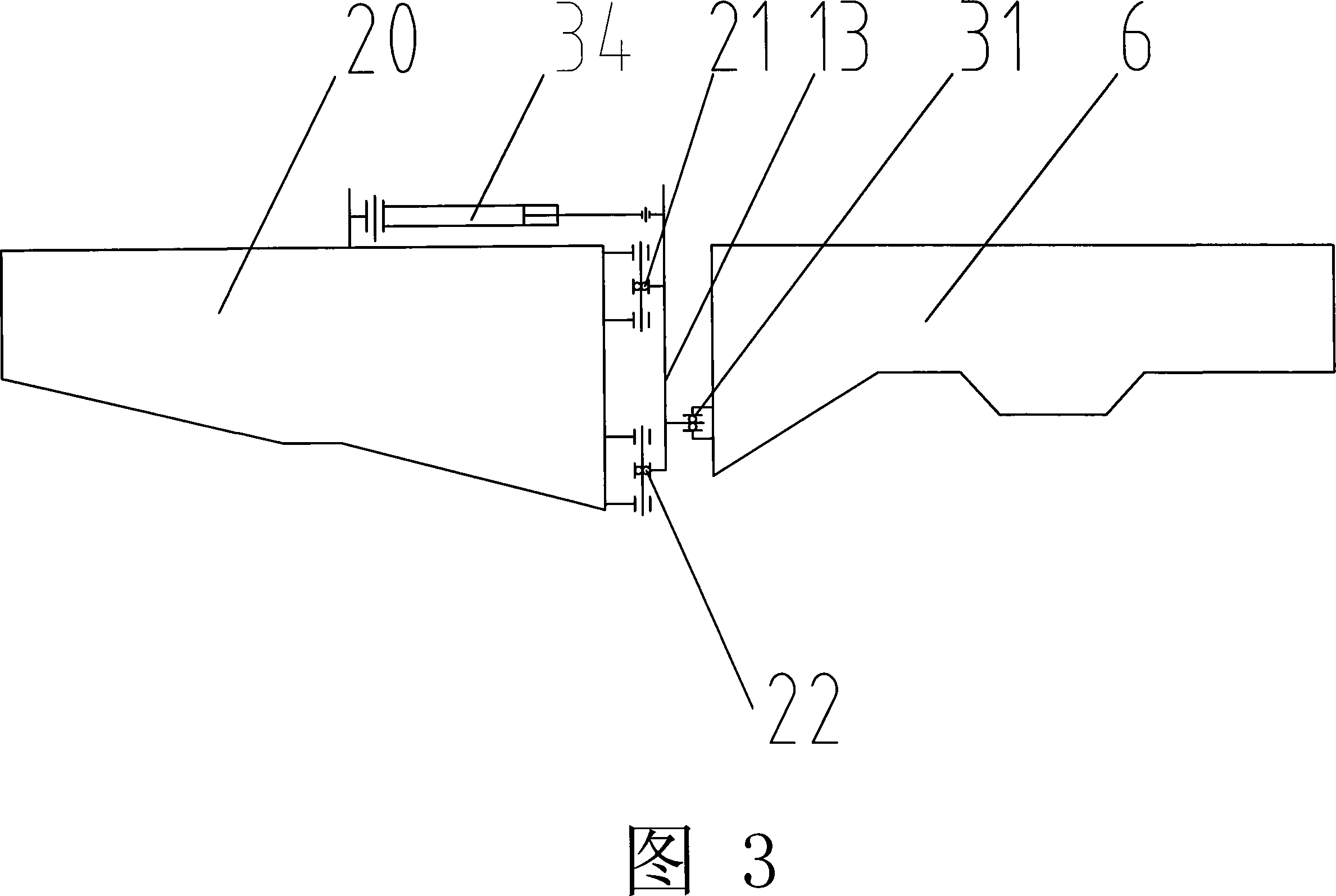

[0018] As shown in Fig. 1, Fig. 2 and Fig. 3, the articulated dump truck chassis of the present invention comprises a girder and front, middle and rear axles, and the girder is composed of a front frame 20, a rear frame 6 and is connected to the front frame Articulated frame 13 between 20 and rear vehicle frame 6 constitutes. The rear end of front vehicle frame 20 is fixed with upper and lower pin seat 24,25, and vertical hinged pin shaft 28,29 is respectively housed in upper and lower pin seat 24,25, and the front end of articulation frame 13 is fixed with respectively. Rotate the upper and lower hinged plates 26,27 that are installed on the hinged pins 28,29, the joint bearings 21,22 are respectively housed in the upper and lower hinged plates 26,27 and the hinged pins 28,29 rotate and cooperate, and the hinged frame The rear end of 13 is fixed with longitudinal rotating shaft 30, and the front end of rear vehicle frame 6 is provided with rotary supporting ring 31, and rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com