Exhaust gas purifying apparatus

A technology of exhaust purification device and exhaust pipeline, which is applied in the direction of exhaust device, electric control of exhaust treatment device, diagnostic device of exhaust treatment device, etc., and can solve problems such as fuel efficiency reduction, engine damage, overpressure, etc. , to achieve the effect of suppressing the reduction of fuel efficiency and preventing uneven deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0081] FIG. 6 shows the configuration of the exhaust purification device 20 according to the first embodiment of the present invention.

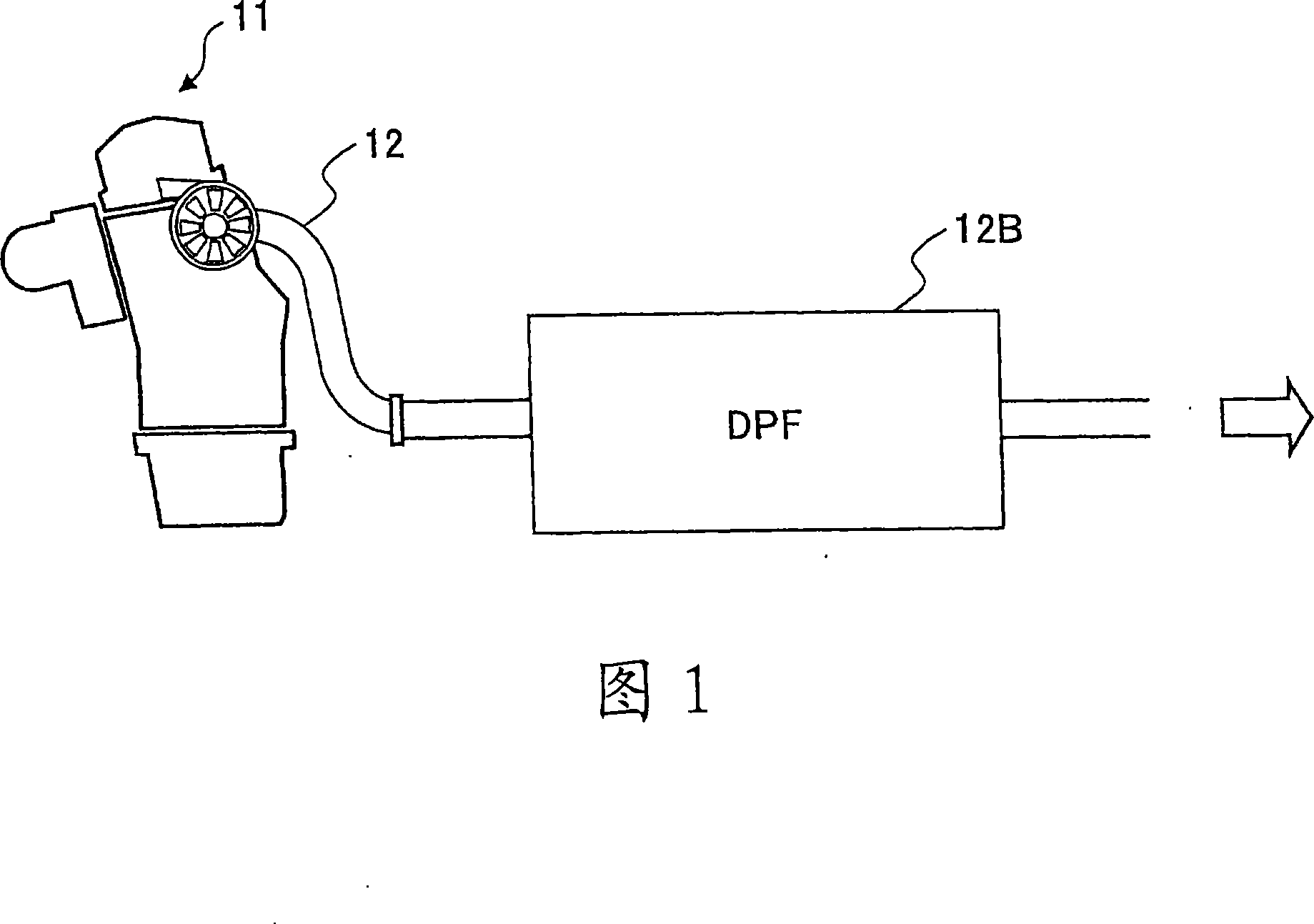

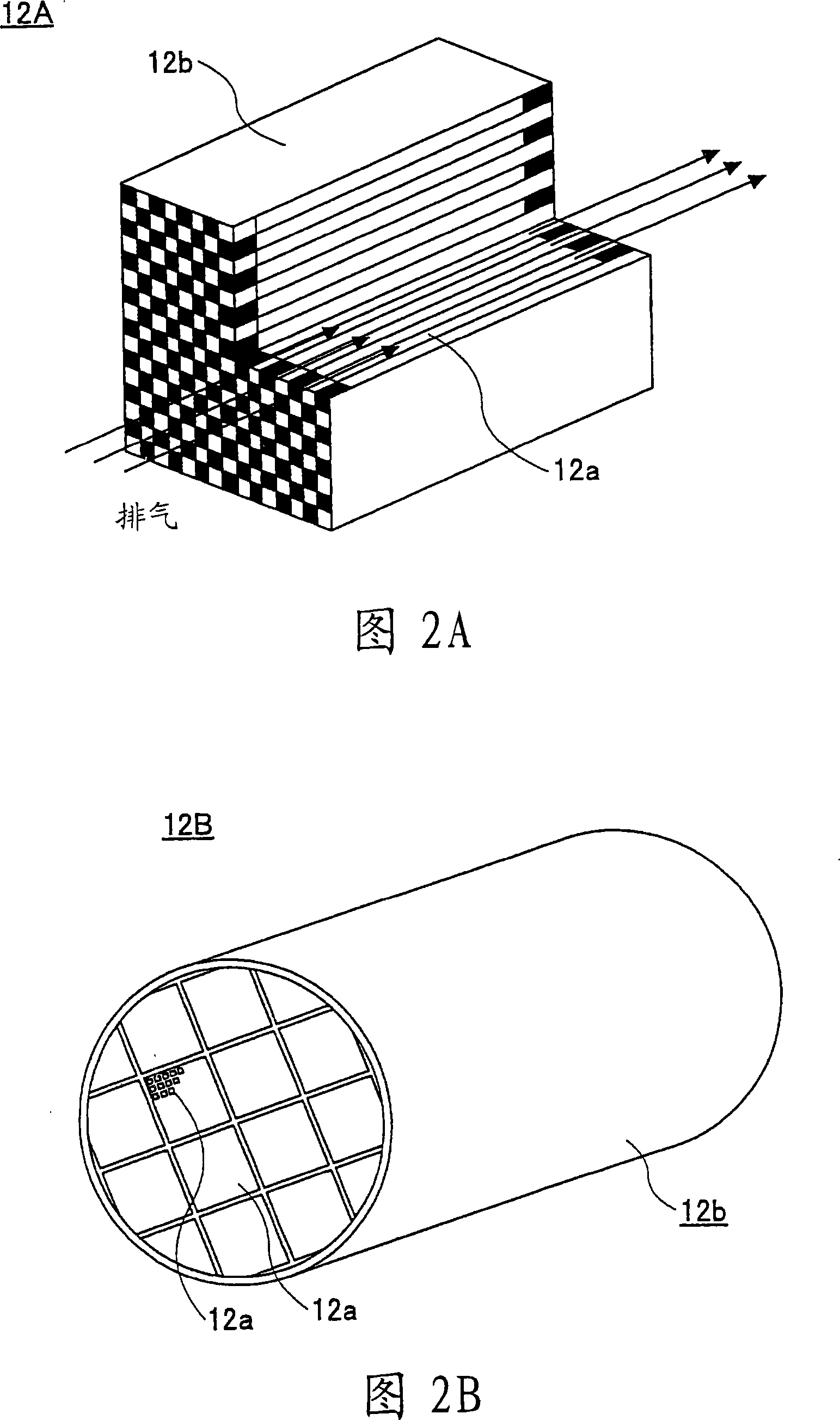

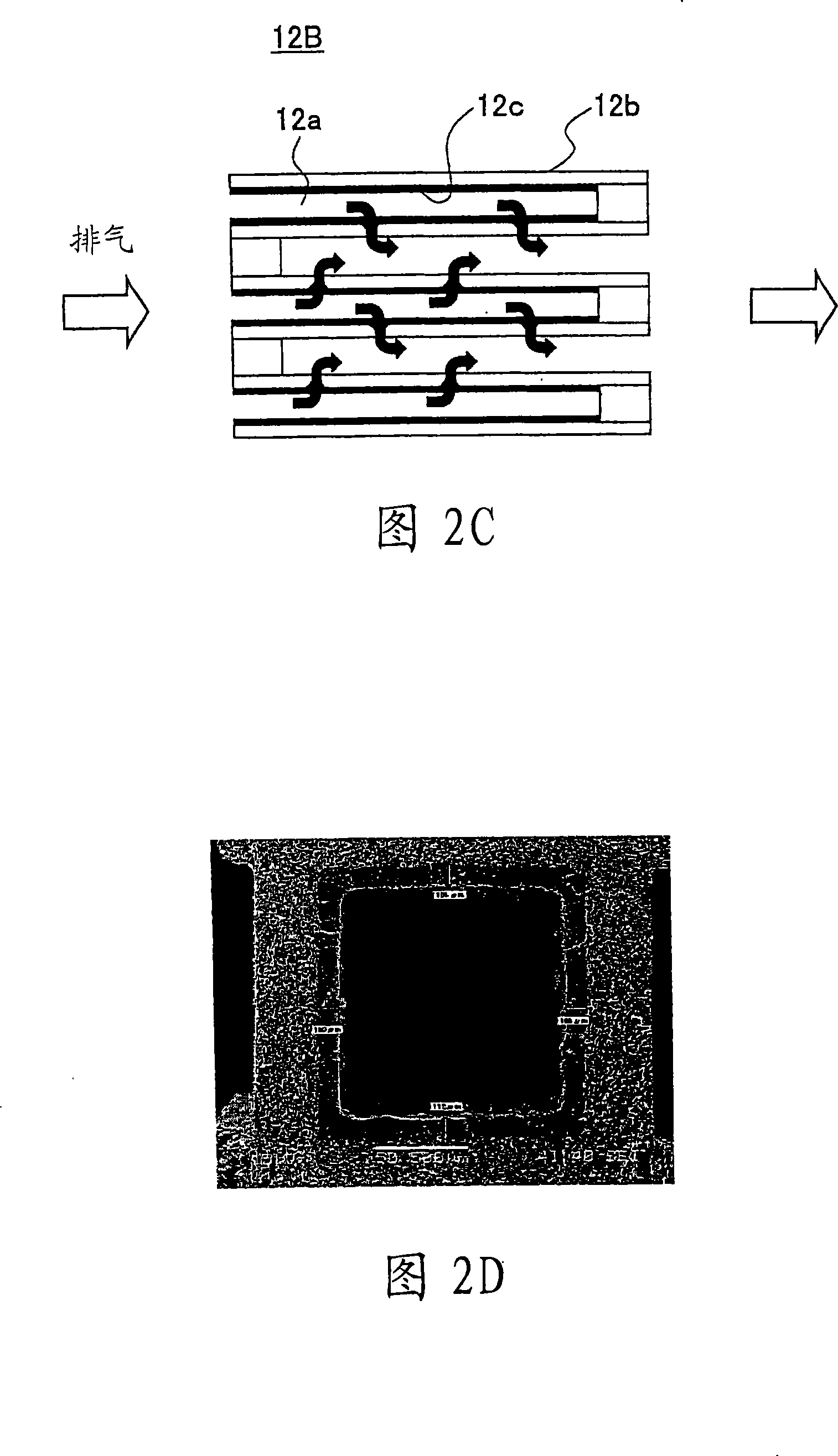

[0082] Referring to Figure 6, exhaust gas from a diesel engine not shown flows via exhaust line 21 into a main diesel particulate filter (DPF) 22 similar to that previously explained with reference to Figure 2A, and as explained with reference to Figures 2C and 2D Yes, the main diesel particulate filter (DPF) 22 collects particulate matter from the exhaust.

[0083] 6, from the upstream side of the main diesel particulate filter (DPF) 22, the auxiliary exhaust line 21A is branched from the exhaust line 21, and a volume smaller than that of the main diesel particulate filter is provided for the auxiliary exhaust line 21A. The secondary diesel particulate filter 22A of the filter (DPF). In addition, a differential pressure gauge 22B is provided for measuring the differential pressure ΔP caused between the inlet and outlet of the sub diesel pa...

no. 2 approach

[0117] FIG. 10 shows a flowchart of an exhaust purification method using the exhaust purification device of FIG. 6 according to a second embodiment of the present invention.

[0118] 10, in step 1, the flow rate in the secondary exhaust line 21A is set to a predetermined value in the range of 50 to 6000 ml / min by using the flow meter 24 (or in some cases, the valve 23), and the flow rate is set by the differential pressure Table 22B to detect the differential pressure ΔP across the secondary diesel particulate filter 22A. In addition, the temperature of the exhaust gas is detected by the temperature measuring portion T1.

[0119] Next, in step 2, the layer thickness W of the particulate matter collected by the sub diesel particulate filter 22A is obtained from the differential pressure ΔP detected in step 1 according to the formula (1). It should be noted here that the temperature T of the exhaust gas can be obtained using the temperature measuring section T2 of the main dies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com