Chain transmission device

A technology of chain drive and chain, which is applied in the direction of transmission device, transmission chain, belt/chain/gear, etc. It can solve the problems of reduced strength, large extension of connecting pins, and large noise, etc., and achieves suppression of wear extension, wear suppression, and noise suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

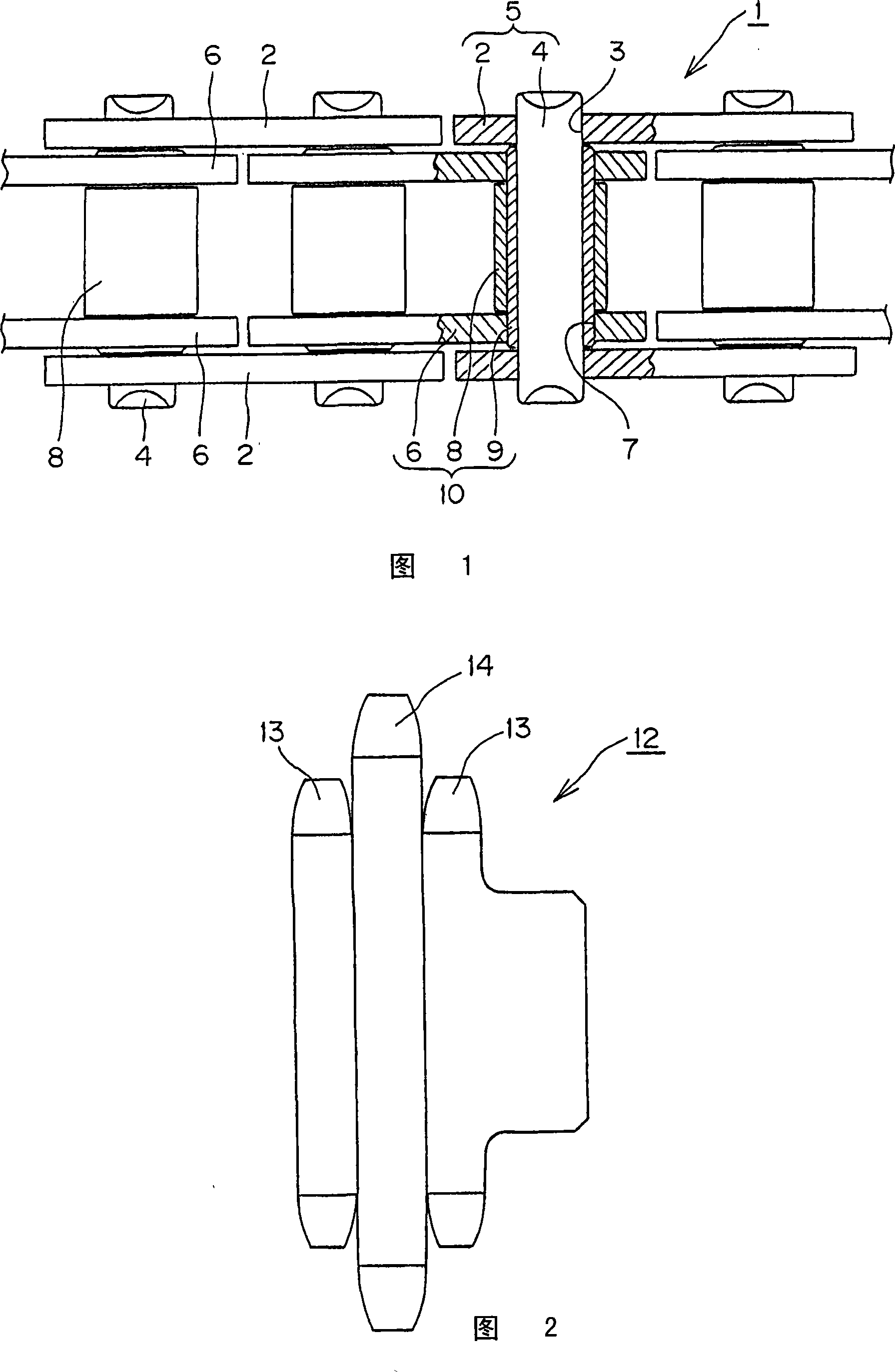

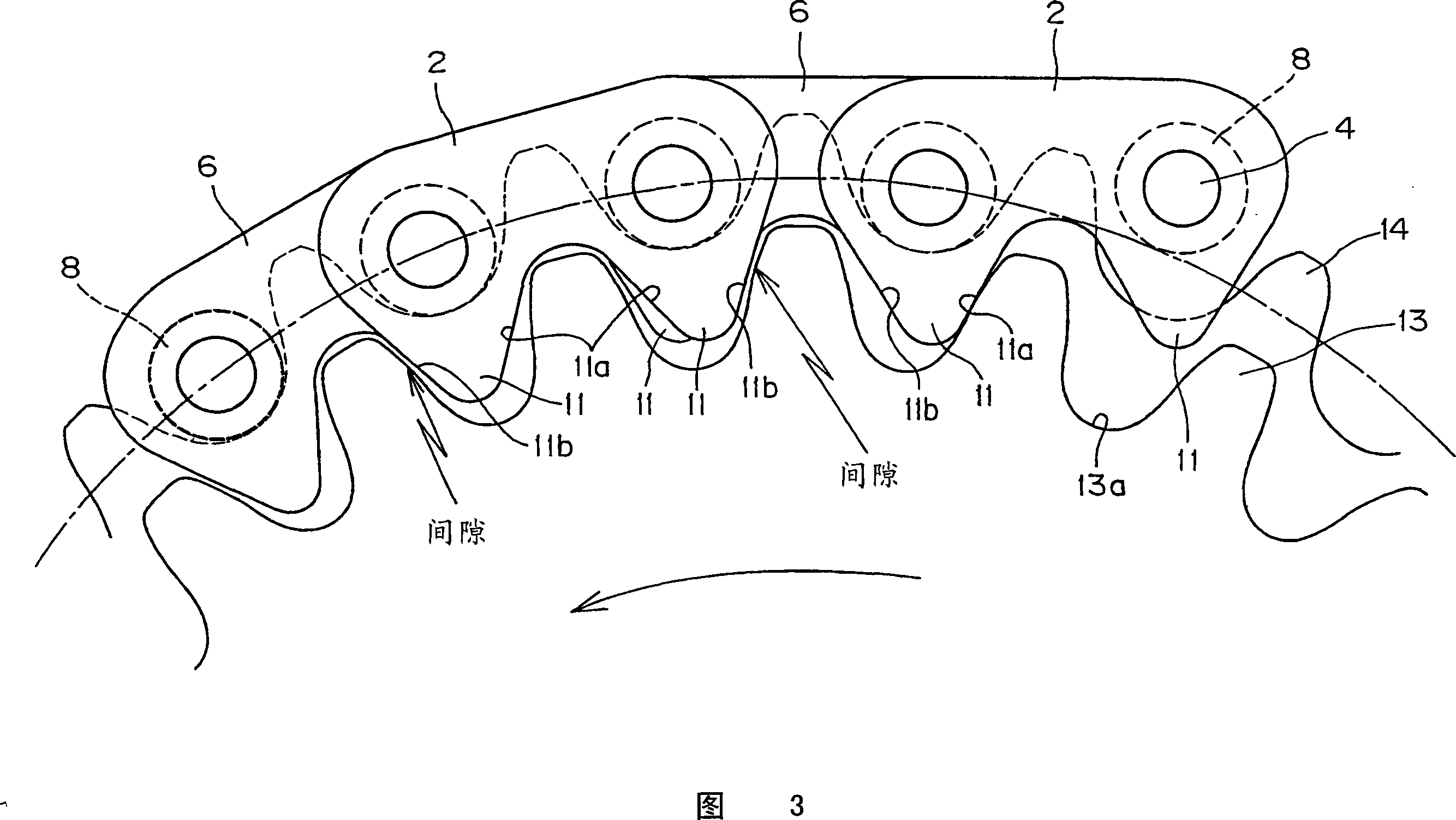

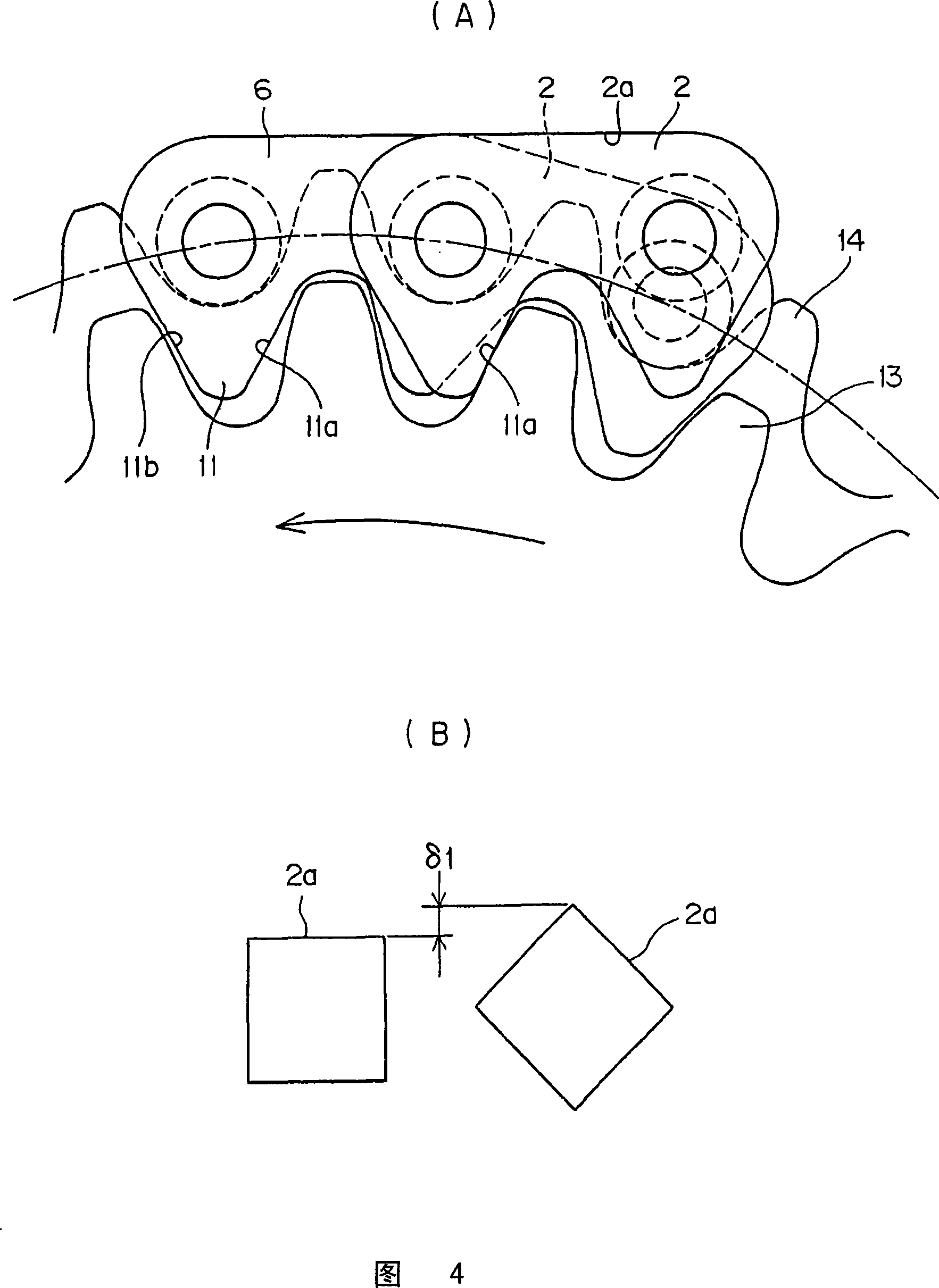

[0042] Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 4 . Fig. 1 is a partial plan view showing the main part of the chain used in the chain transmission device in Embodiment 1 of the present invention in cross section, Fig. 2 is a front view of a sprocket, Fig. 3 is an explanatory diagram of the meshing state of the chain, and Fig. (A) is an explanatory diagram of the meshing operation of the link plates, and (B) is an explanatory diagram schematically showing the polygonal motion of the chain.

[0043] This Embodiment 1 chain transmission (not shown) consists of a chain and a sprocket, and the chain has a plurality of chain plates having a pair of teeth and rollers.

[0044] As shown in Figure 1, the chain 1 includes: the outer chain link 5 that inserts the two ends of the connecting pin 4 and is fixed in the pin hole 3 of a pair of outer chain plates 2; The sleeve 9 is embedded and fixed in the inner chain link 10 in the sleeve hole 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com