Silent chain

A technology of silent chain and chain link, applied in the field of silent chain, can solve the problems of poor meshing, reduced wear resistance, wear, etc., and achieve the effect of stable meshing state, improving plane accuracy and improving distance accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

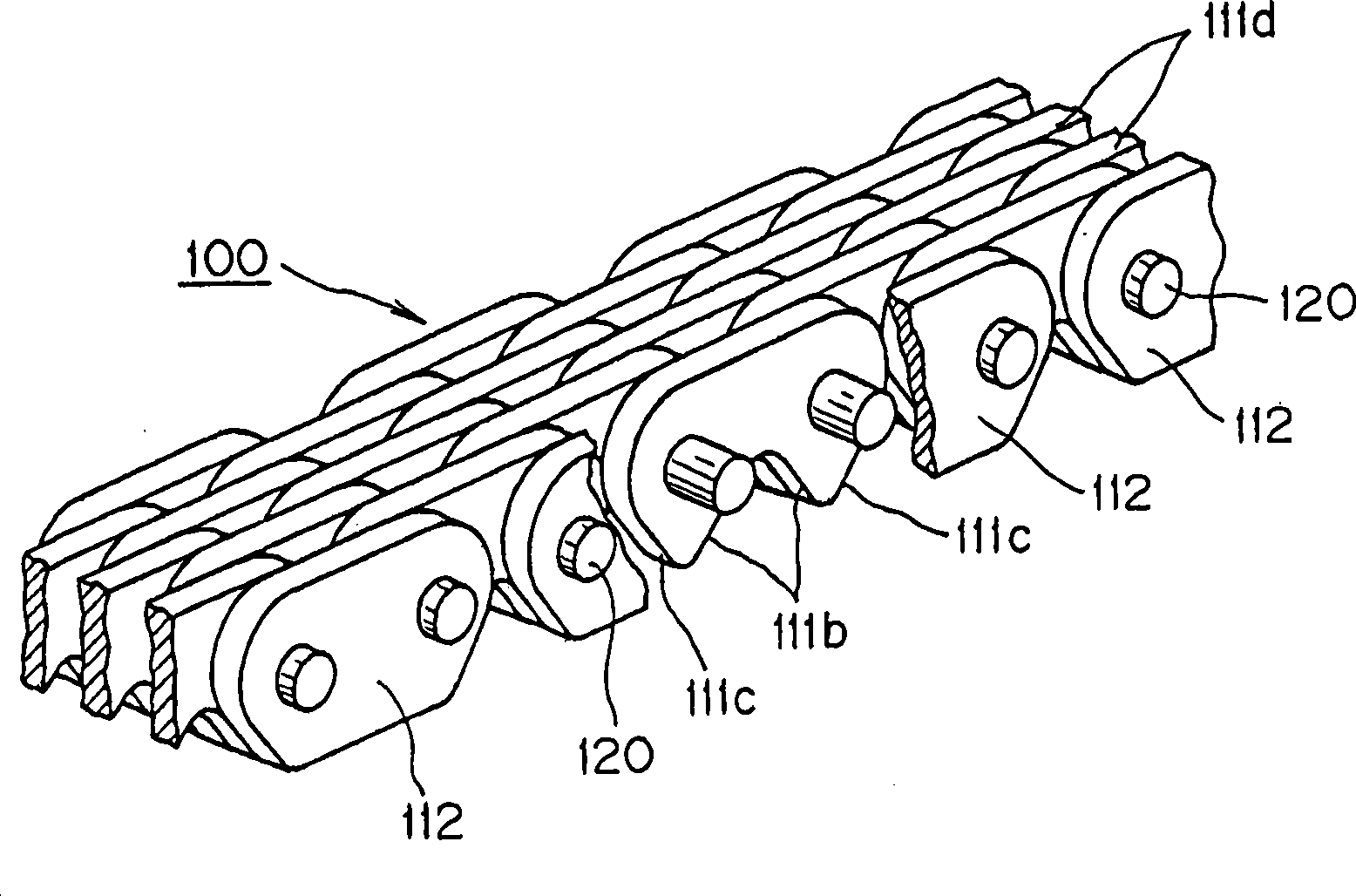

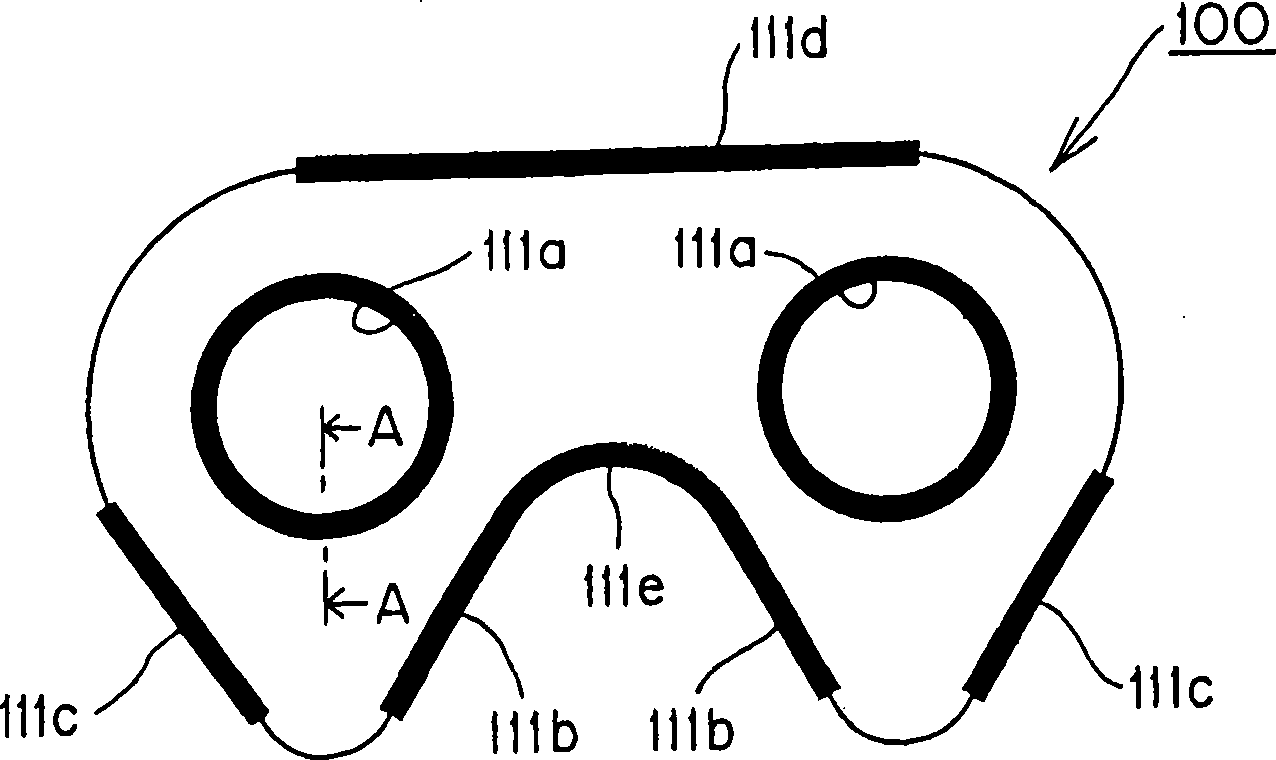

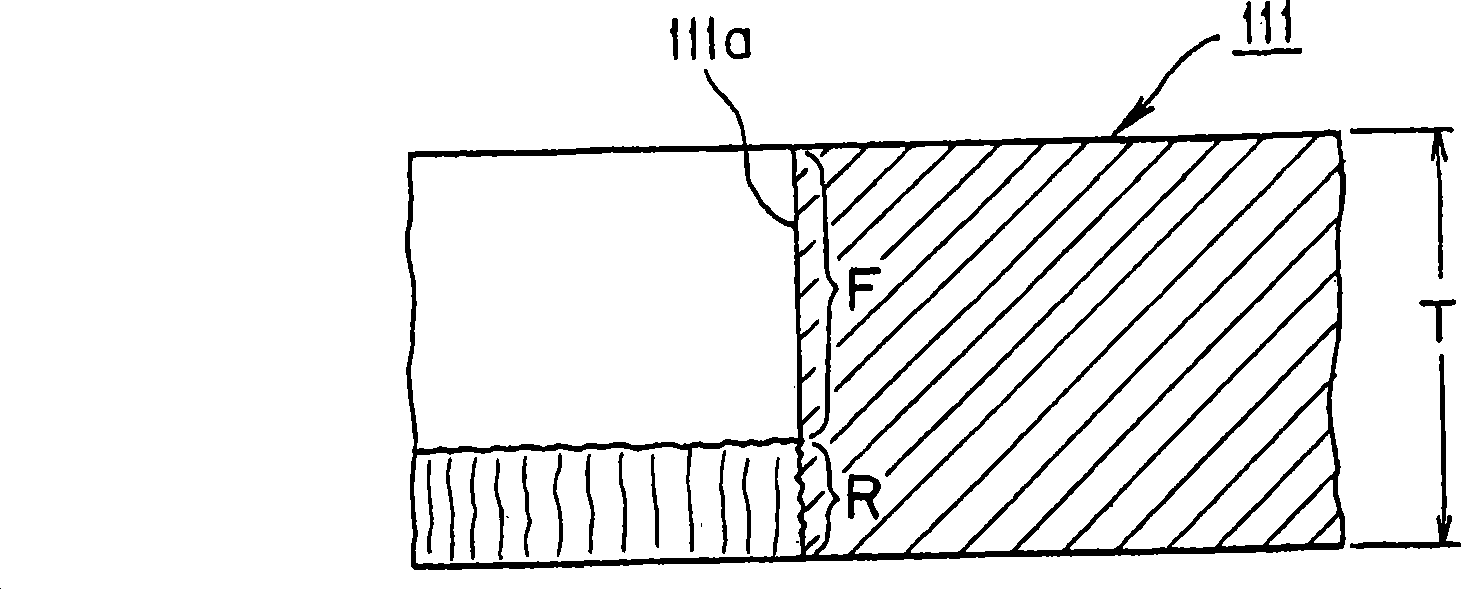

[0050] In the silent chain of the present invention, a link row formed by randomly arranging a plurality of link plates side by side in the chain width direction is intersected with each other by connecting pins inserted into the inner surfaces of the pin holes of the link plates. Connected, and after the inner meshing surface of the link plate starts to mesh with the sprocket, the outer meshing surface of the link plate is engaged in a seated state to transmit power. The inner meshing surface, the inner surface of the pin hole, and the outer meshing surface have shear surfaces simultaneously formed in the range of 70% or more of the plate thickness by the shaving process after the punching process, and the front and back of the chain link plate are randomly formed. The configuration achieves good left-right balance in the chain width direction and stable meshing with low noise and low vibration, and suppresses the fatigue damage of the link plate and the wear and extension of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com