Double stator double rotor motor of solid rotor start-up and squirrel-cage rotor operation, and the start-up and operation method

A dual-rotor motor, squirrel-cage rotor technology, applied in motor generators/starters, electrical components, electromechanical devices, etc., can solve problems such as limited application, unsatisfactory operating performance such as efficiency, power factor, etc. The effect of implementing a simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Taking the application of the present invention on an IP23 radially ventilated motor as an example to illustrate its structure and its starting and running method, it is obvious that the present invention is not limited to this type of motor.

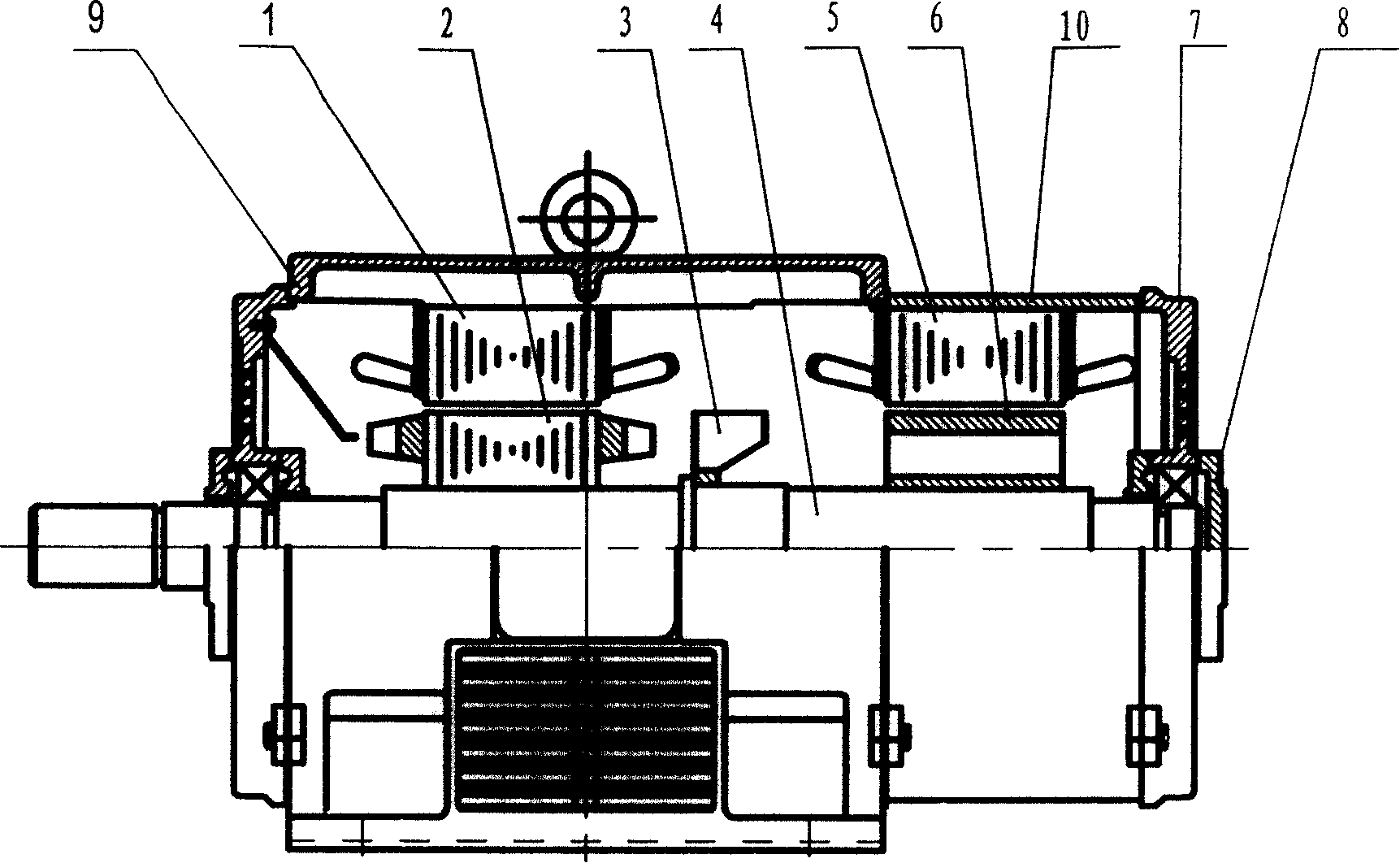

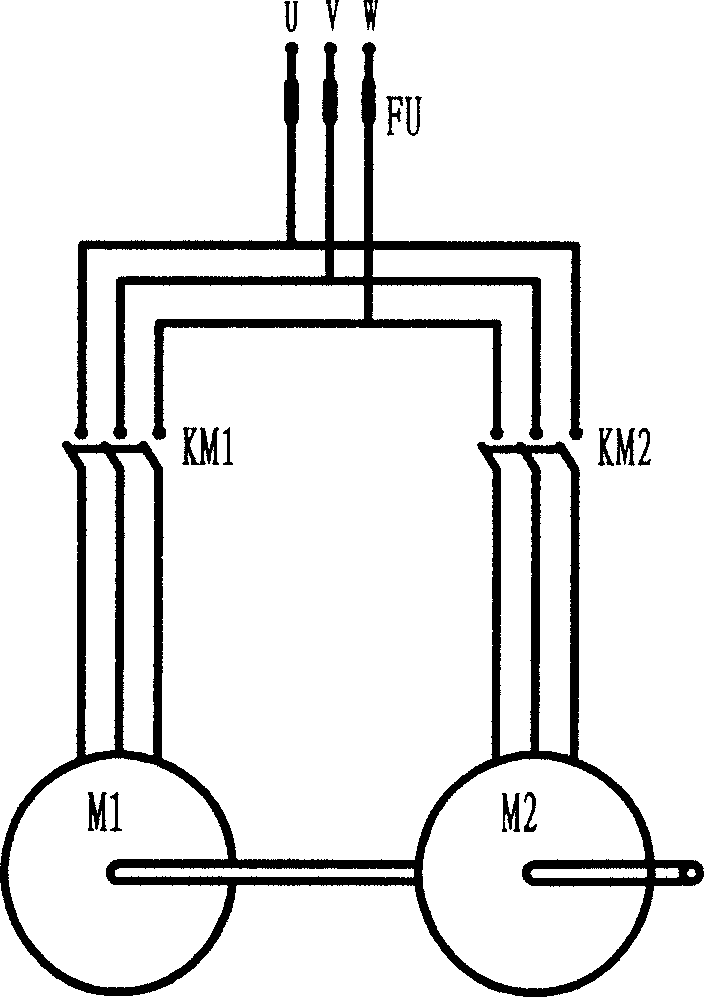

[0015] Such as figure 1 , the main stator 1 has the same number of poles as the detachable stator 5, and is fastened into double stators with the same axis through the well-known notches of the casing. Constitute a coaxial dual rotor, the main stator 1 corresponds to the squirrel cage rotor 2, the removable stator 5 corresponds to the solid rotor 6, and they are assembled with the end covers 7 and bearing systems 8 installed at both ends to form a solid rotor A coaxial building block double-stator double-rotor motor operated by a starter squirrel-cage rotor.

[0016] The main stator 1 includes a fixed casing 9 and a stator core with windings connected to the mouth of the fixed casing according to a known structure. The stator co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com