Pneumatic tire

A technology for pneumatic tires, new tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as damage to belt layers, auxiliary belt layers, failures, etc., to improve traction performance , The effect of preventing stones from being trapped and inhibiting uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

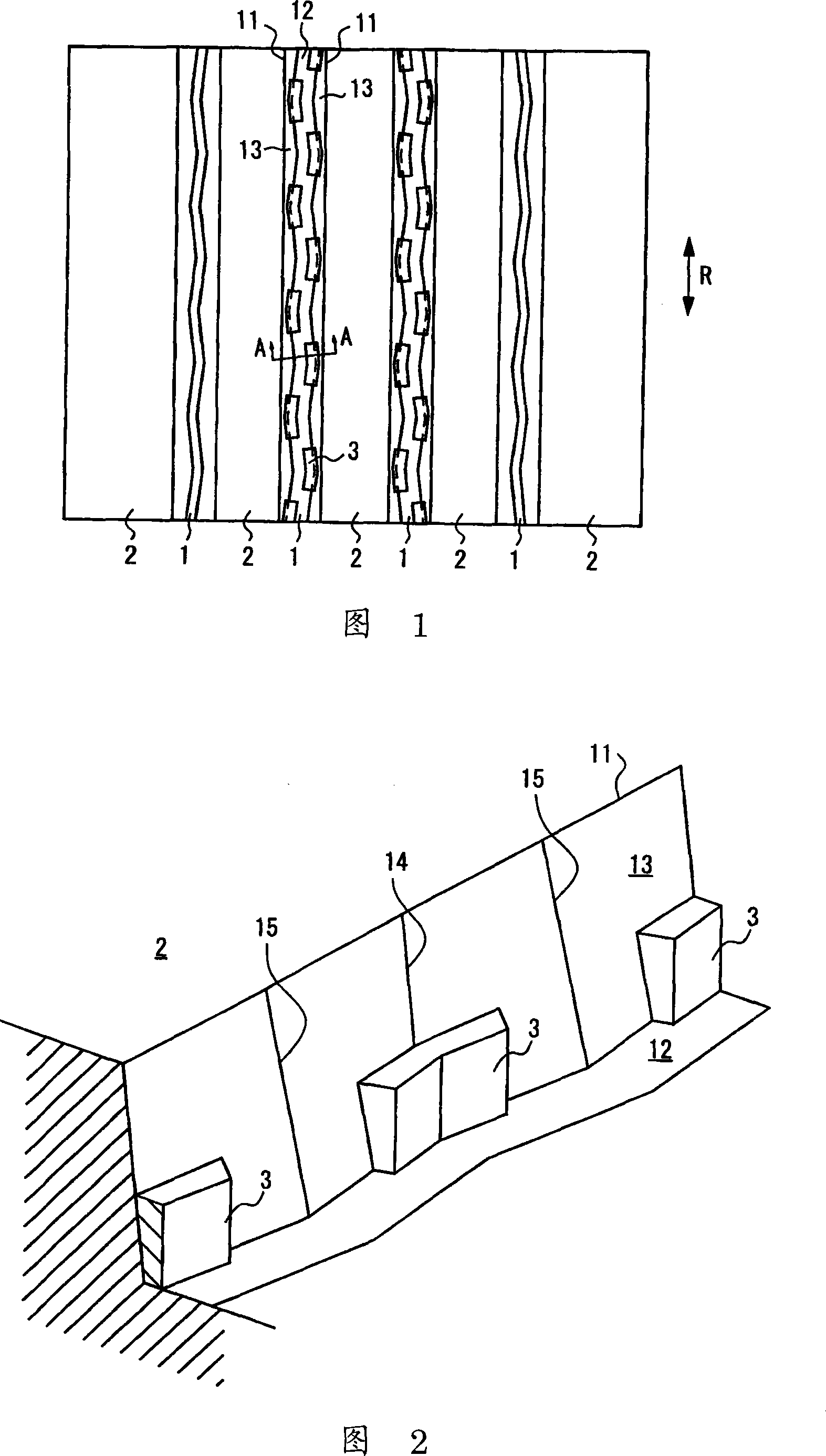

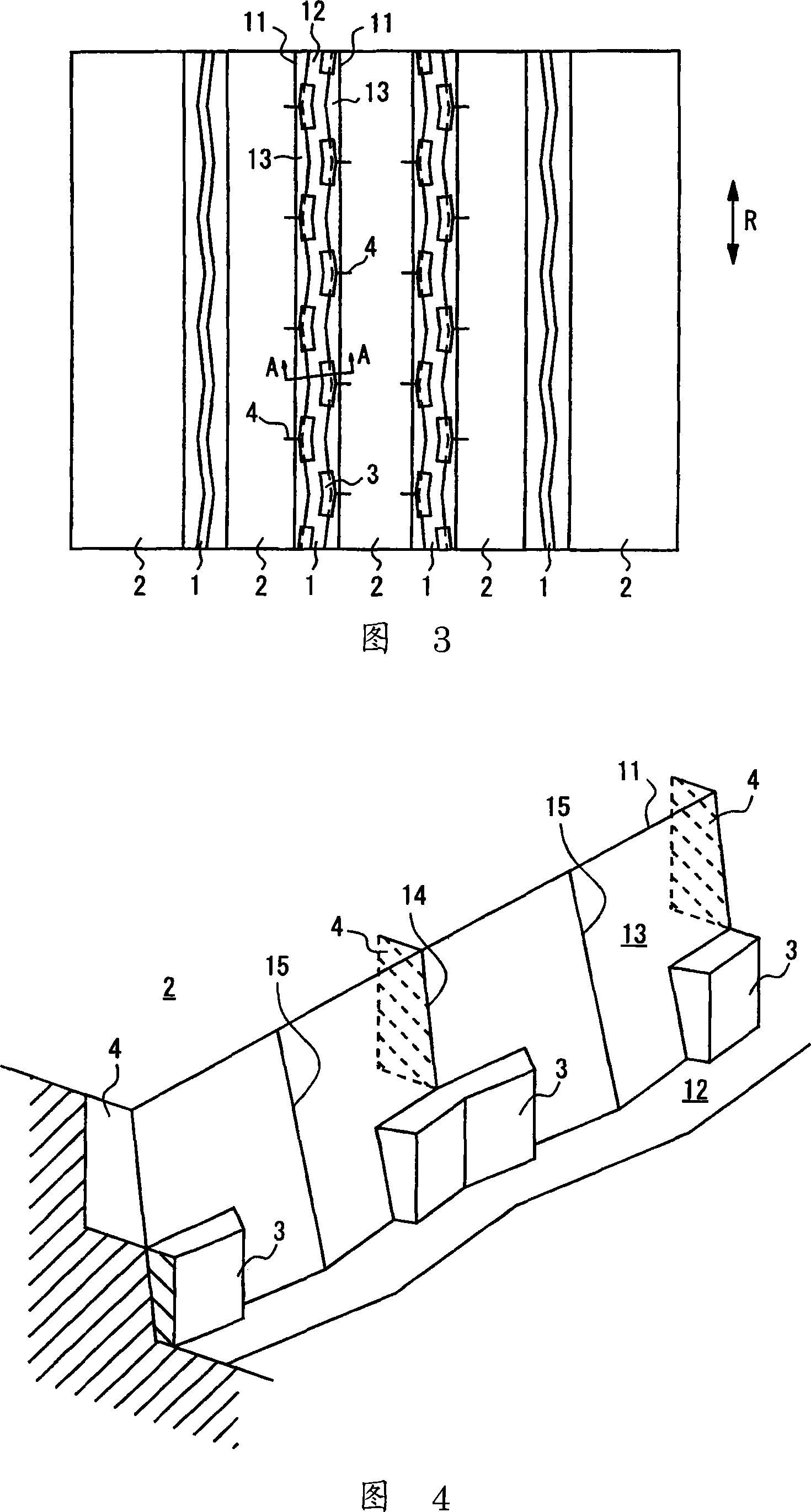

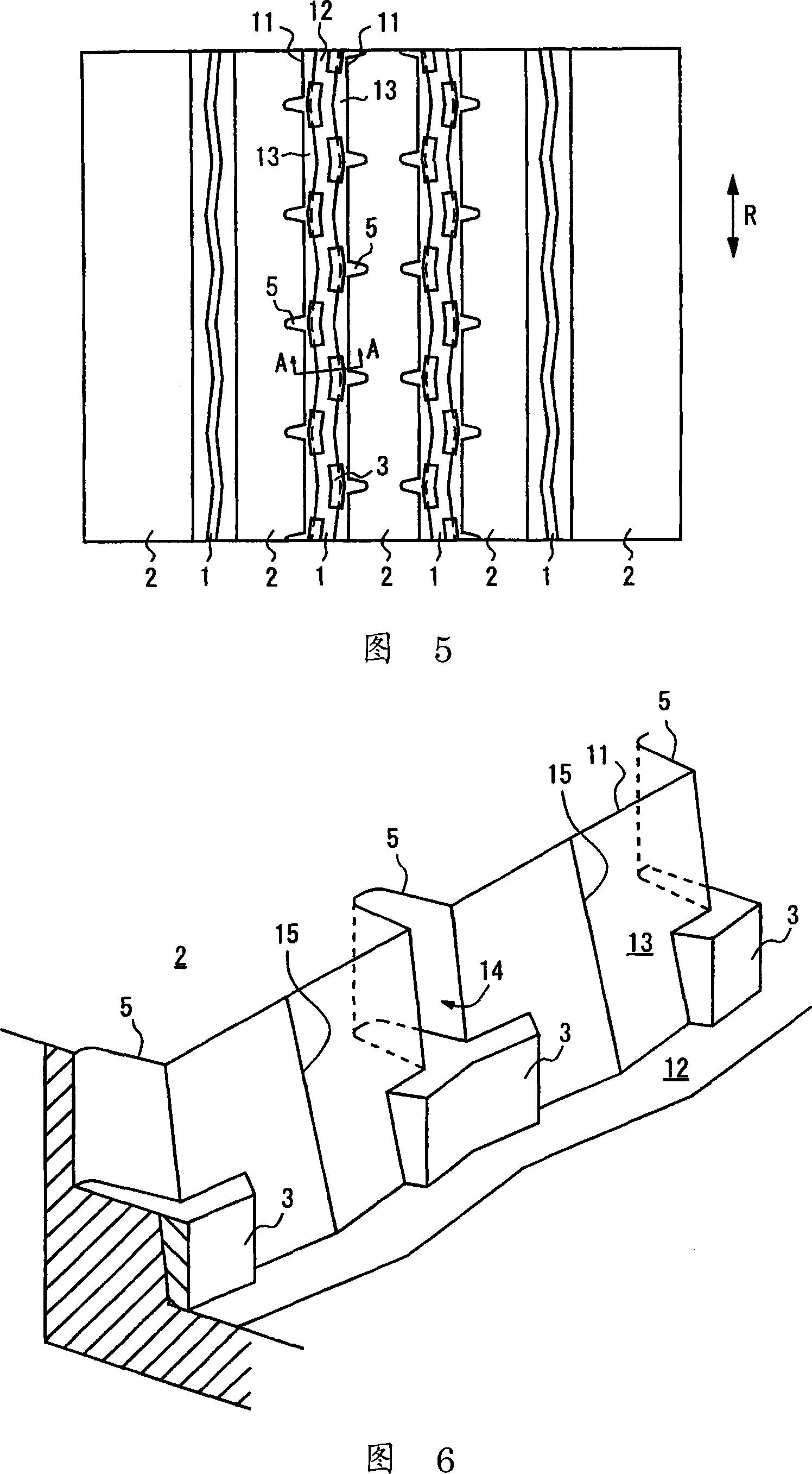

[0039] As an example, a pneumatic tire of the present invention was tested and mounted on a truck (axle structure 2-D) with a load of 10 tons for evaluation. In addition, the tread patterns of Examples 1 to 3 are the patterns shown in FIGS. 1 , 3 , and 5 , respectively. The depth D of the main groove 1 is 14.5 mm, the height H of the protrusion 3 is 3 mm, W, W1, and W2 in Figures 8 to 10 are 7 mm, 4.5 mm, and 6.5 mm, respectively, and L1, L2 are 23 mm, 17 mm, respectively. The width of shaped pattern 2 is 38mm. The length of the sipe 4 in embodiment 2 is 2.5 mm, the length of the notch 5 in embodiment 3 is 4 mm, and the width of the opening on the side wall 13 is 5.5 mm.

[0040] The tires of Conventional Examples 1 to 3 do not have protrusions having the same patterns as those of Examples 1 to 3. However, Conventional Example 2 has the same sipe as Example 2, and Conventional Example 3 has the same notches as Example 3. The tire of Conventional Example 4 has the same patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com