Self-steering orbit type container gantry crane and steering method thereof

A rail-type, container-based technology, applied in the direction of transportation and packaging, load hanging components, trolley cranes, etc., can solve the problems of difficult transition, high cost, low efficiency, etc., and achieve the goal of solving difficult and efficient transition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

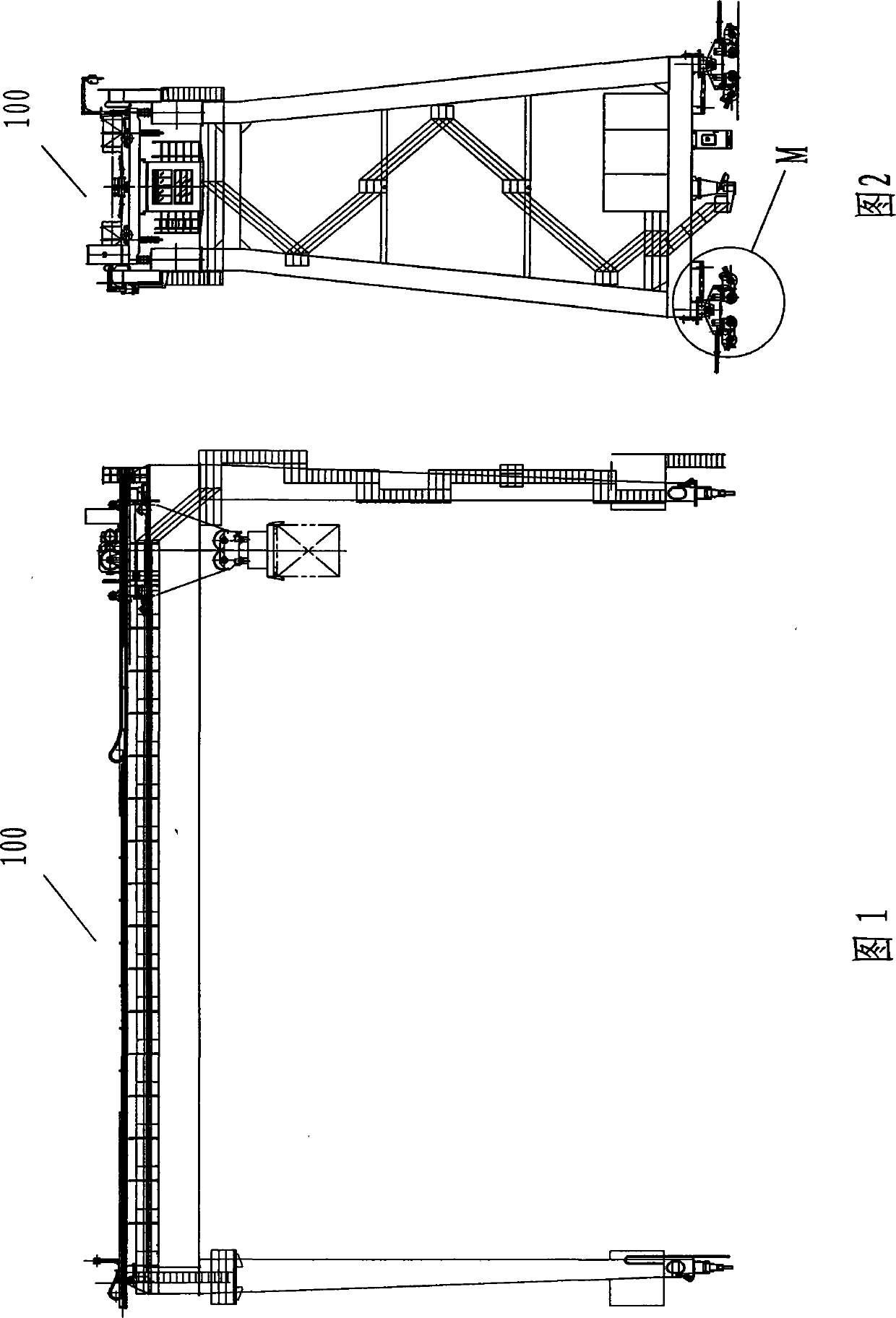

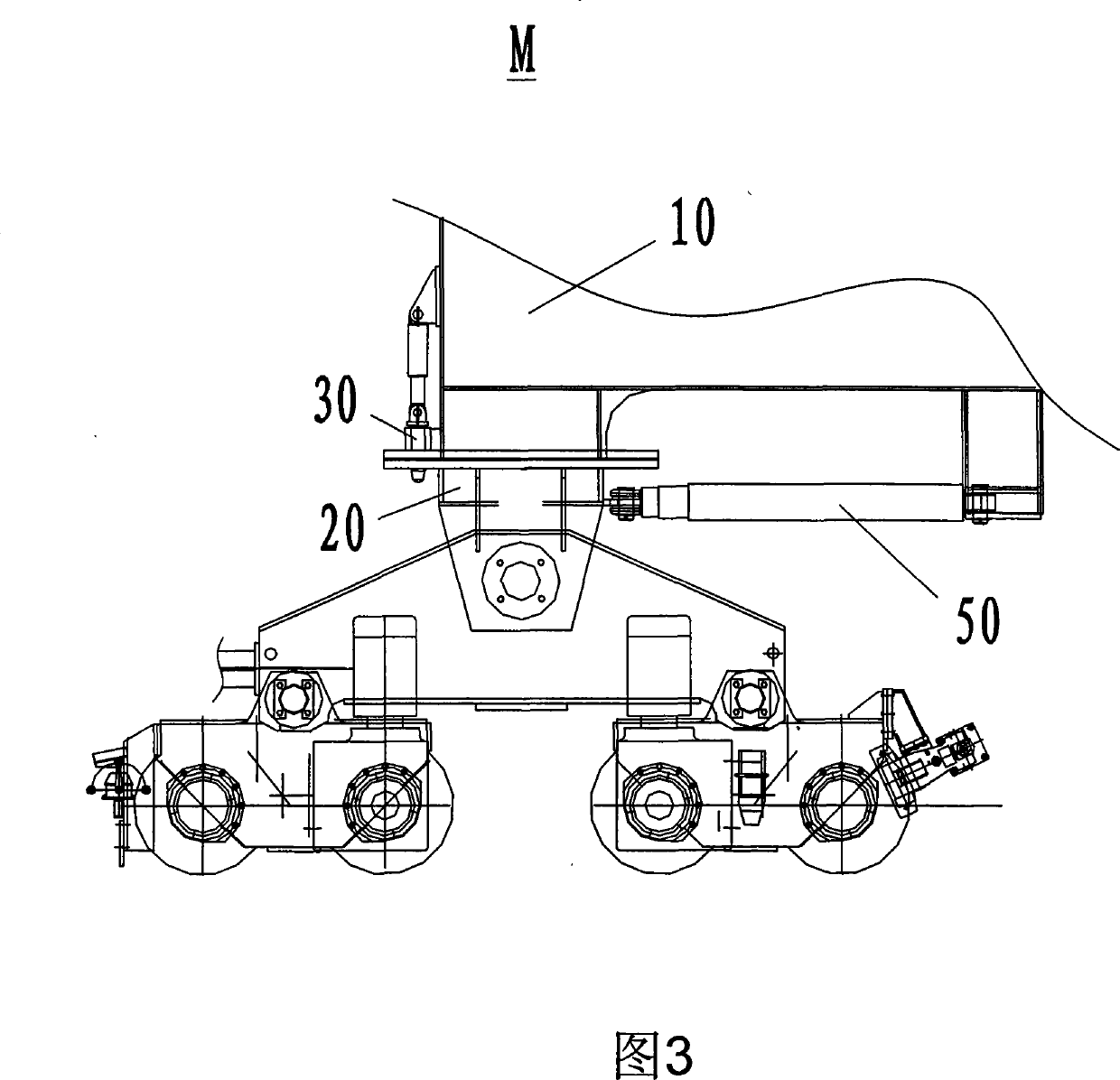

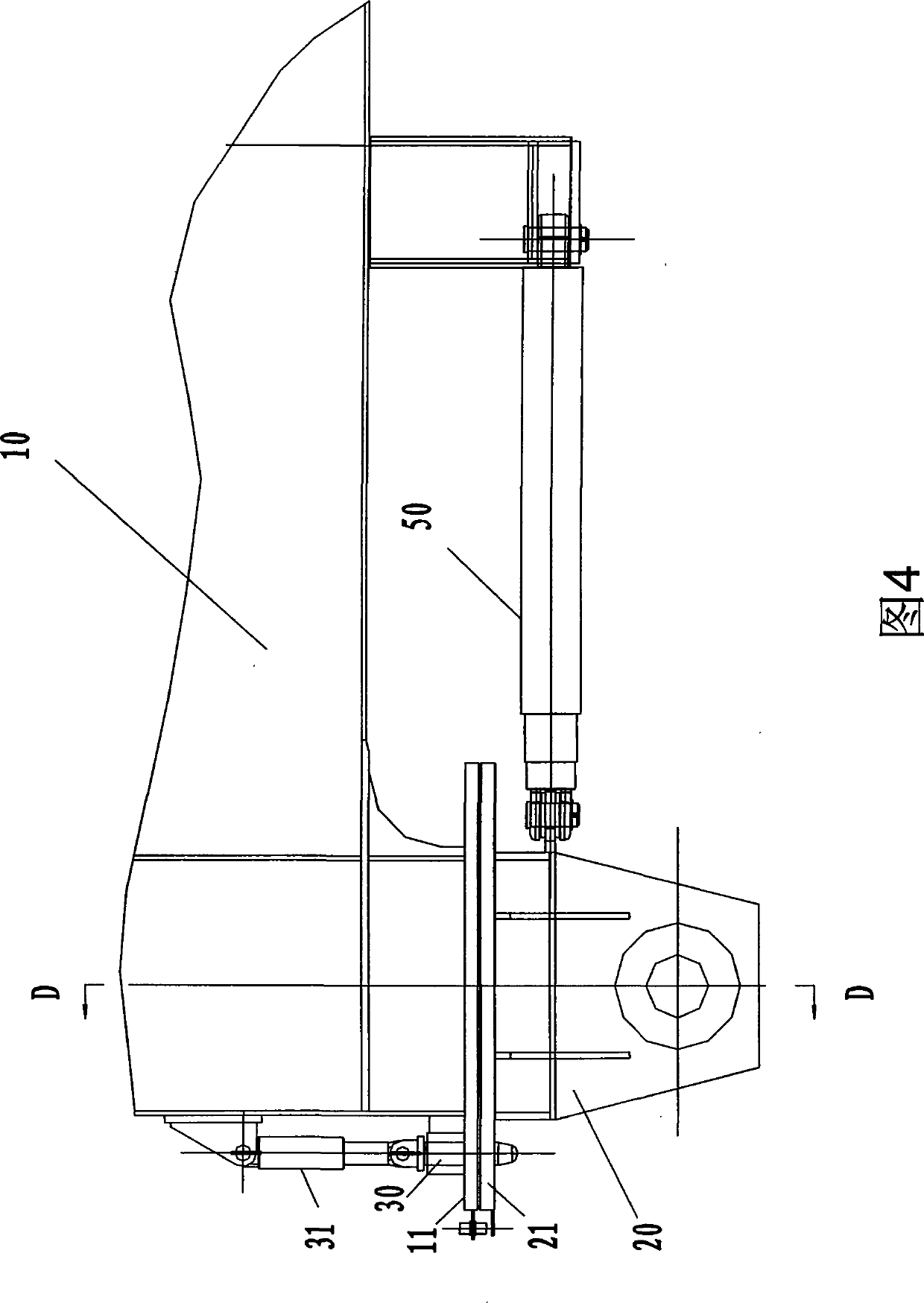

[0032] Referring to Fig. 1 and Fig. 2, the present invention provides a self-steering rail-mounted container gantry crane and its transfer method. Referring to Fig. 3, a self-steering rail-mounted container gantry crane 100 includes a lower beam 10 and a wheel box 20. Lower beam 10 is connected with described wheel box 20 by rotating shaft 40 (referring to Fig. 5), and wheel is installed below wheel box 20, and described lower beam 10 and wheel box 20 are fixed by pin shaft 30 of vertical direction, and described lower beam 10 There is a push rod 50 connected with the wheel box 20 to drive it to rotate around the rotating shaft 40 in the horizontal direction.

[0033] With reference to Fig. 5, the upper part of the rotating shaft 40 is fixed to the lower beam 10, the rotating shaft 40 has a shoulder 41, and the shoulder 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com