Axial rolling bearing

A technology of rolling bearings and bearings, which is applied in the field of parts supporting the axial movement of mechanical workpieces, can solve the problems of large frictional force of axial movement and increased matching clearance, and achieve the effects of less frictional force, saving money, and good movement clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

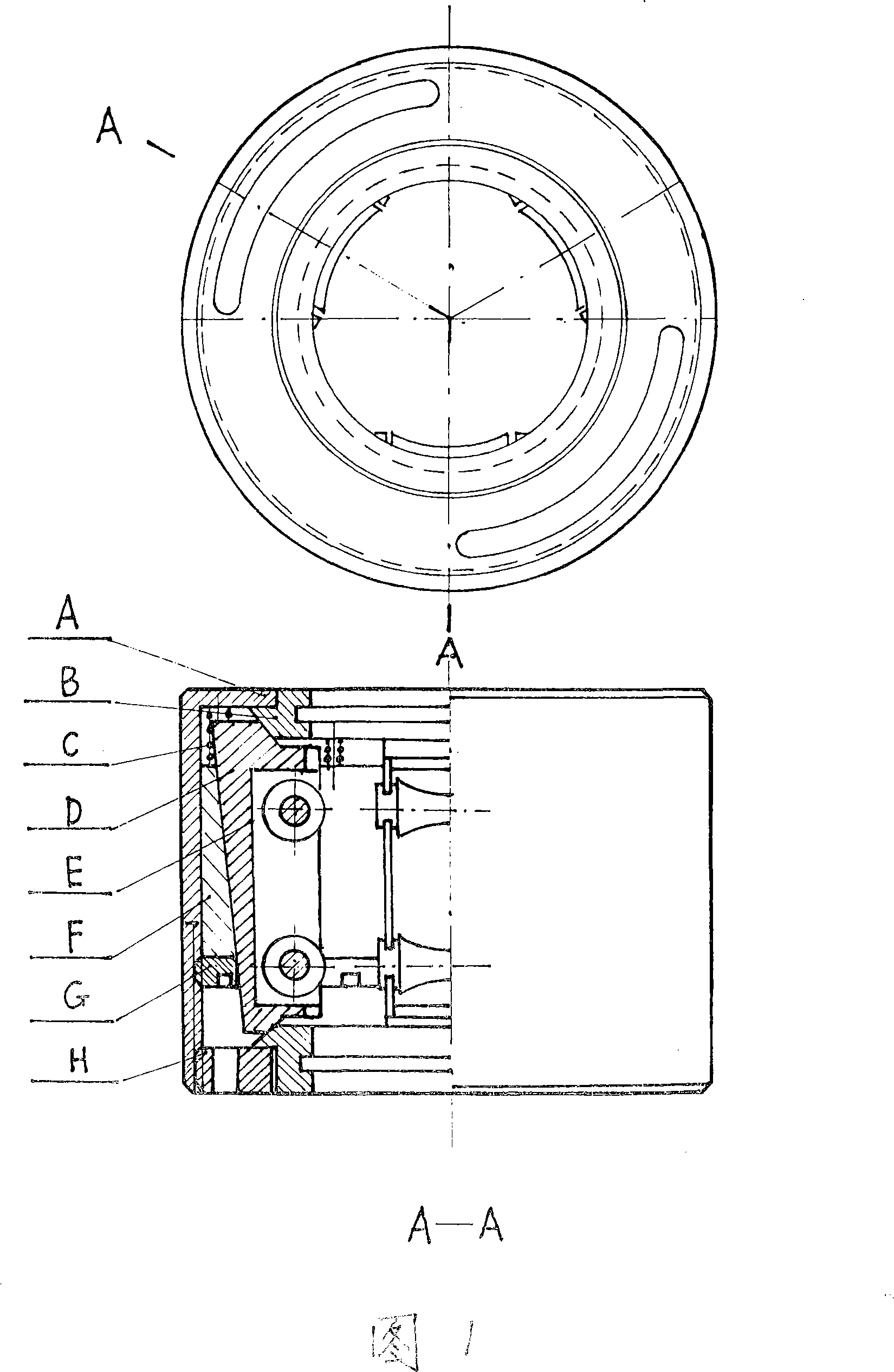

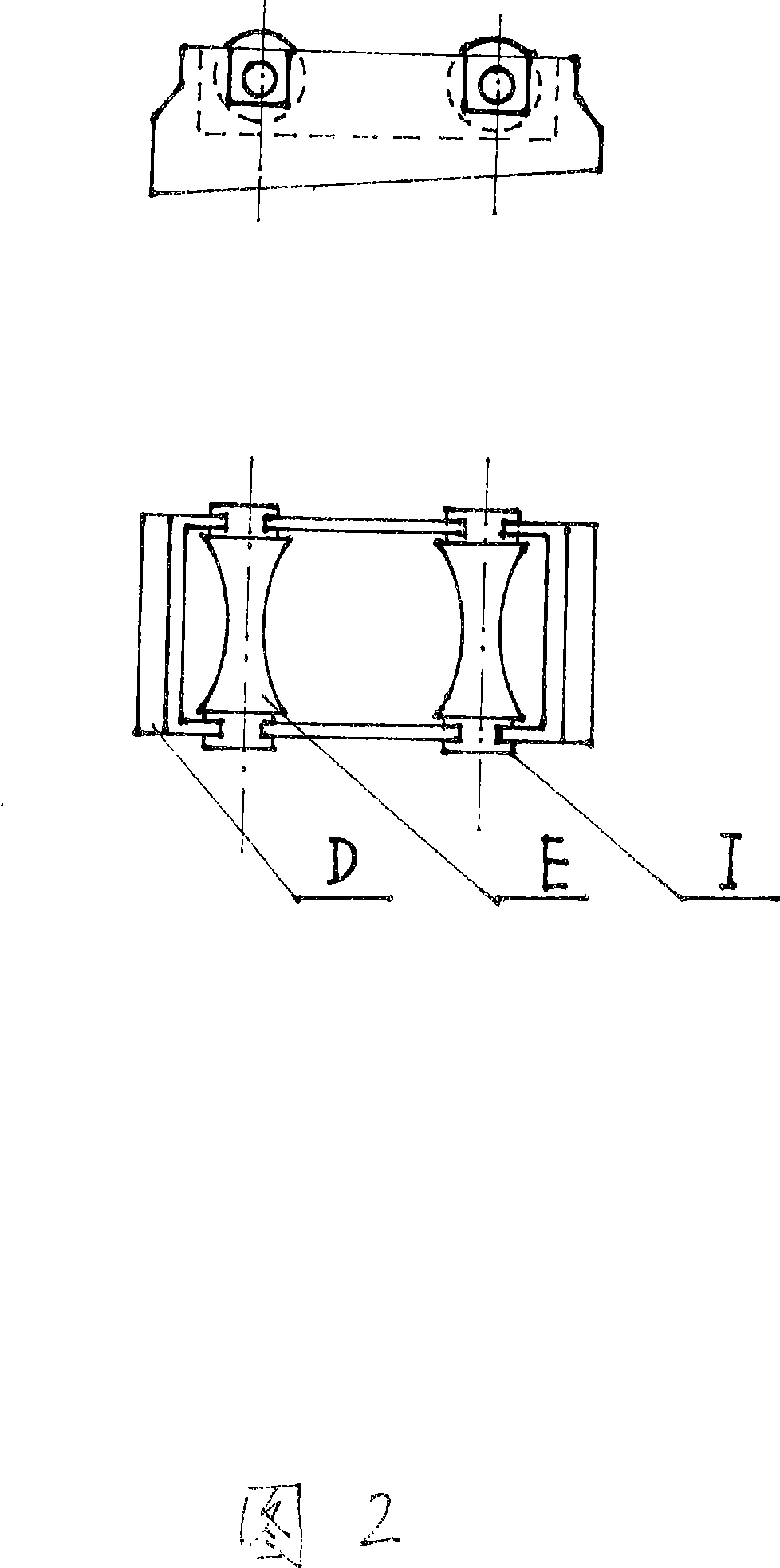

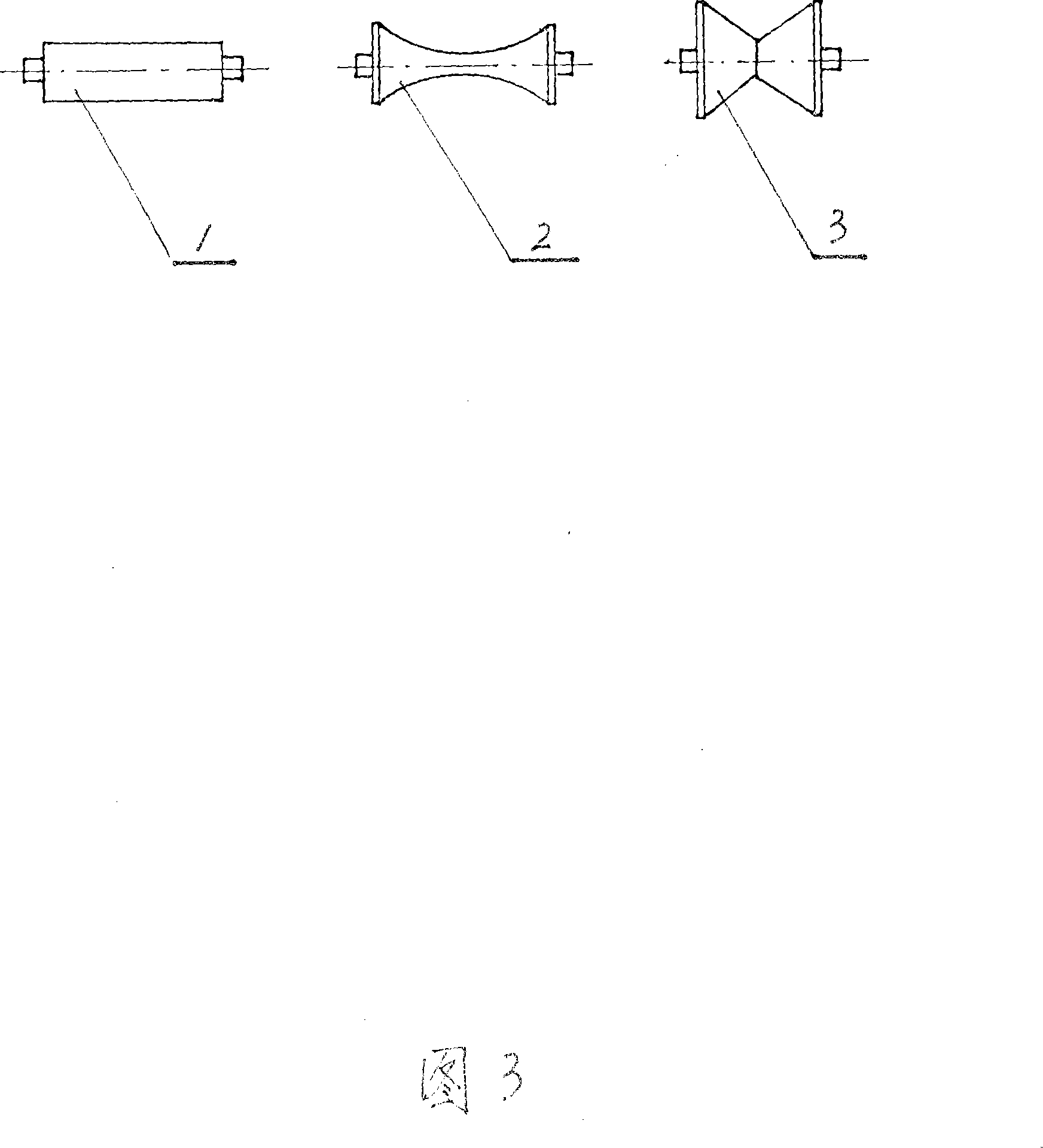

[0014] In Figure 1, the two ends of the inner diameter of the outer ring (A) of the axial rolling bearing are equipped with locking rings (B), and the two-ring slopes are stuck on the slope of the rolling group bracket. The wedge (F) is open and circular, and has 3 places The guide groove of the rolling group bracket, the outer diameter is matched with the inner diameter of the bearing outer ring (A), the rolling group bracket (D) is installed in the inner diameter guide groove, and the locking ring (H) is pressed against the locking ring ( B) on. When adjusting the inner diameter of the bearing, you can adjust the ring (G) to rotate forward or reverse through the long arc holes at the 2 places of the locking ring (H), and push the wedge pad (F) and the rolling group bracket (D) to move, so the inner diameter of the bearing is change, then tighten the locking ring (H) so that the rolling group does not loosen and ensure a good working gap between the roller ball (E) and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com