Large damp magnetic suspension high speed rotating system device

A high-speed rotation and system device technology, applied in the field of magnetic levitation, can solve the problems of few practical applications and the inability to greatly improve the system support damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

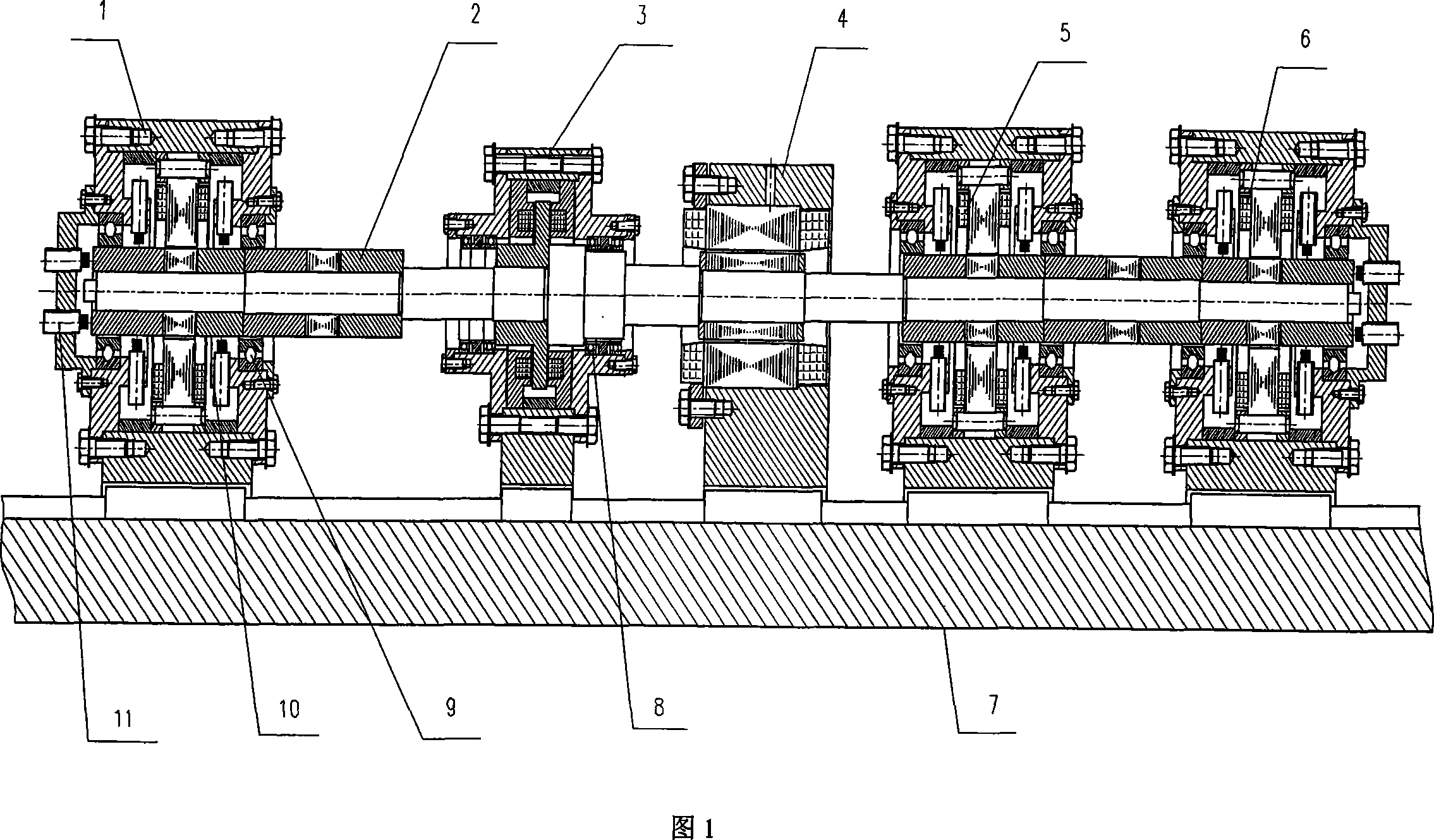

[0026] As shown in FIG. 1, the device of the present invention includes radial magnetic suspension bearing assemblies 1, 6, rotor assembly 2, thrust bearing assembly 3, high-frequency drive motor assembly 4, base 7, thrust protection bearing 8, radial protection bearing 9, Radial sensor 10, axial sensor 11. The magnetic bearing provides support for the rotor in 5 degrees of freedom. For each degree of freedom, a closed-loop system is composed of sensors, controllers, power amplifiers, magnetic bearings, and rotors. Under the action of appropriate control parameters, the magnetic bearing produces support stiffness and support damping for the rotor, which determines the dynamic performance of the entire system. Due to the limited stable region of the control parameters, the choice of support damping is limited.

[0027] The device of the present invention adds an auxiliary magnetic suspension support assembly 5 on the basis of the general magnetic suspension bearing rotor syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com