Self-sealing rotary compensator

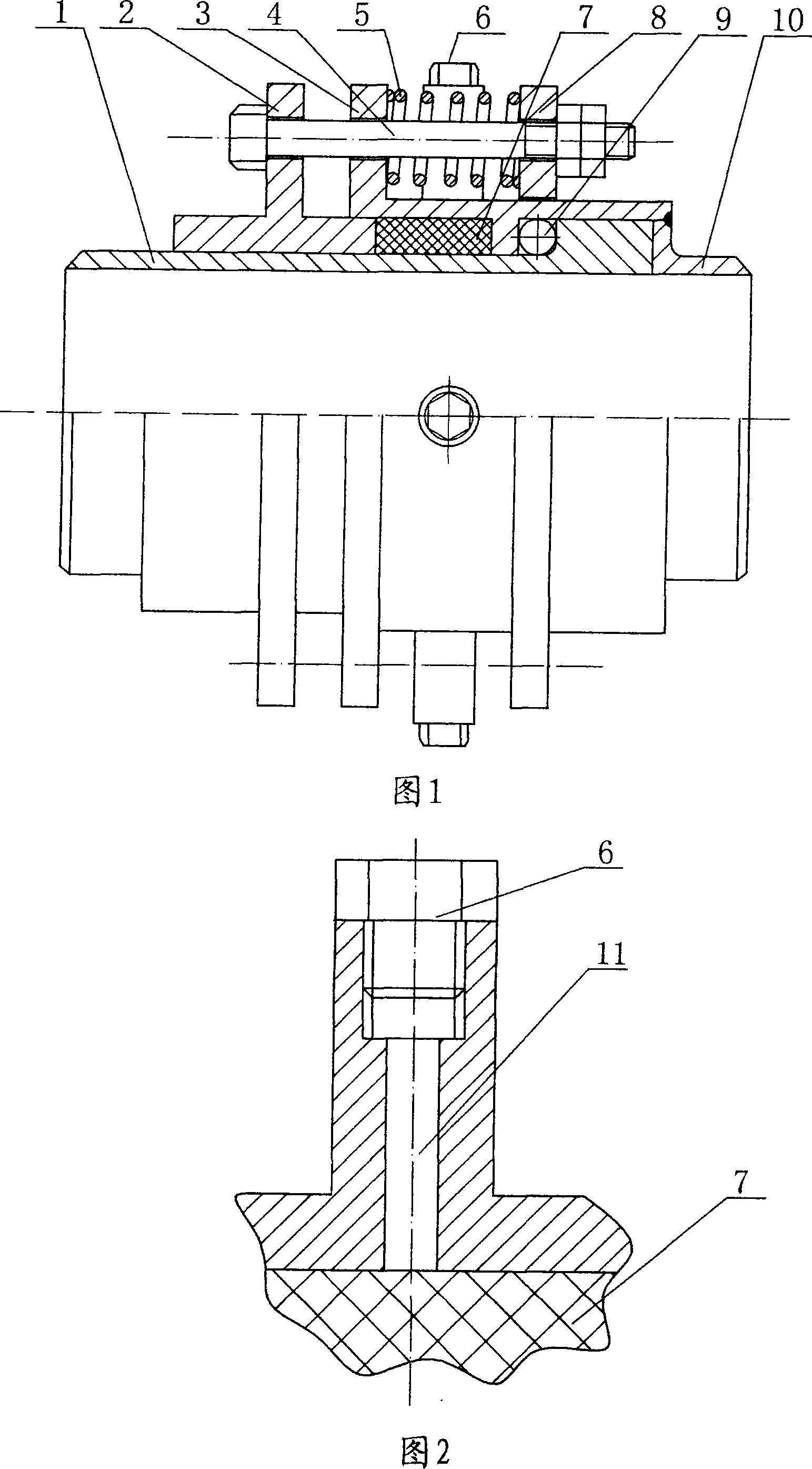

A rotary compensator and self-sealing technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of not being able to replenish sealing materials online, so as to avoid economic losses and facilitate injection , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0015] Embodiment 2 has the same application occasions as Embodiment 1, except that the size of the diameter is different, and the number of radial through holes 11 provided on the outer wall of the housing 3 is different. The self-sealing rotary compensator with a diameter of 1000 mm in this embodiment is provided with 28 radial through holes 11 and screw plugs 6 on the outer wall of its housing 3, which can meet the requirements of online supplementary sealing material 6, and the specific operation is the same as that of the embodiment 1 is the same.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap