Stepping type hydraulic lifting mechanism

A hydraulic lifting, step-by-step technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of lifting height limitation, height can not be very low, complicated, etc., to achieve the effect of convenient angle adjustment and small lifting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

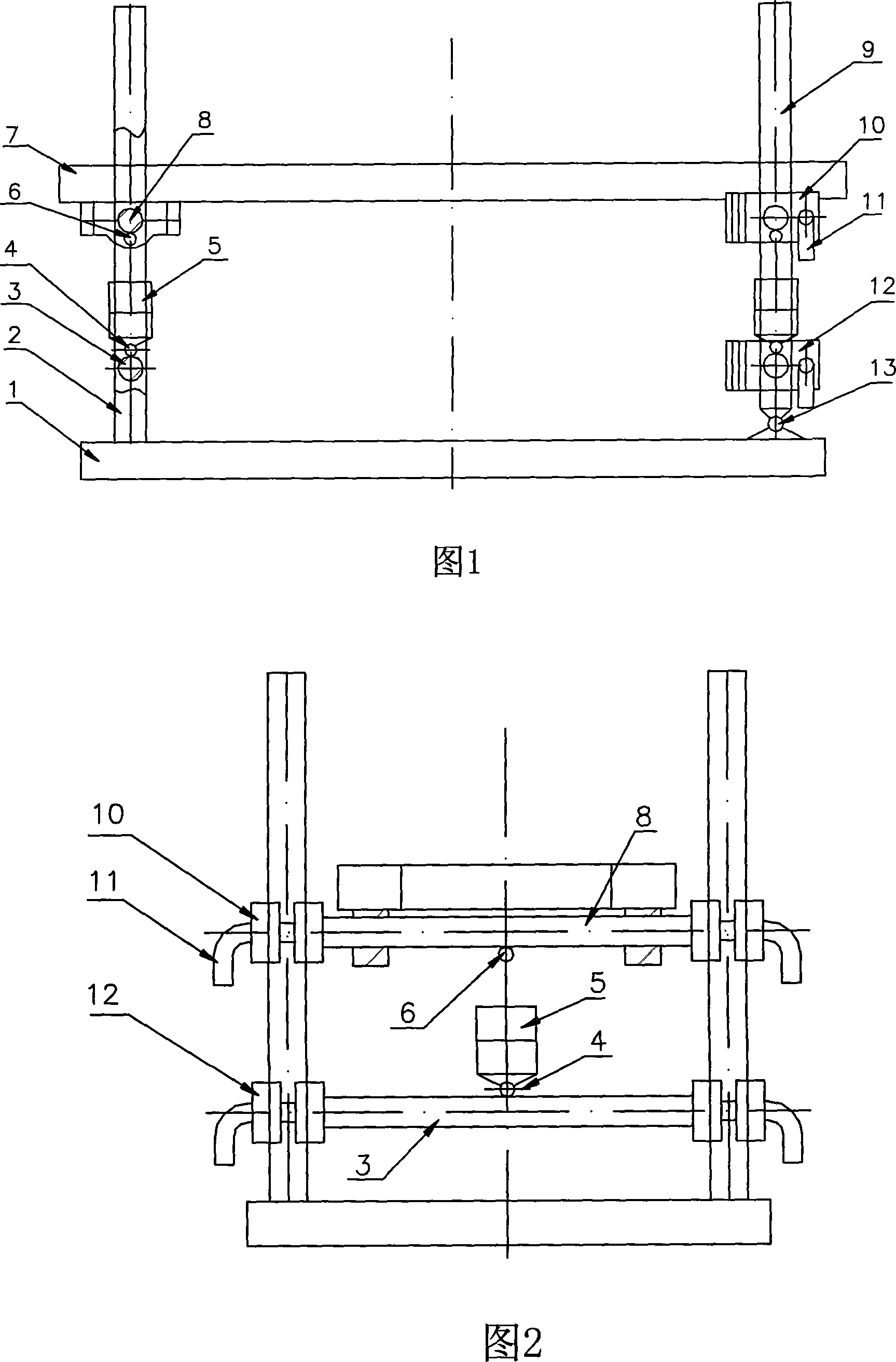

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The left column 2 is fixed on the lower frame 1, the right column 9 is hinged on the lower frame 1, and the right column 9 can swing left and right. The hoop slider is sleeved on the column, and when the handle 11 is unclamped, the hoop slider can slide up and down along the column, and when the handle is locked, the hoop slider is fixed on the column. The upper and lower bars between the left columns in the figure are perpendicular to the columns and fixedly connected with the hoop slider, that is, the upper rail 8 is fixedly connected with the upper hoop slider 10, and the lower rail 3 is fixedly connected with the lower hoop slider 12. , the upper cross bar 8 and the lower cross bar 3 are parallel to each other, the two ends of the oil cylinder 5 are respectively hinged with the upper cross bar 8 and the lower cross bar 3, and the axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com