Differential with inclined lubrication ports

A differential and port technology, applied in the direction of differential transmission, gear lubrication/cooling, components with teeth, etc., can solve the problems that cannot be reduced in size, reduce the flow rate of lubricating oil, and endanger the performance of differential components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

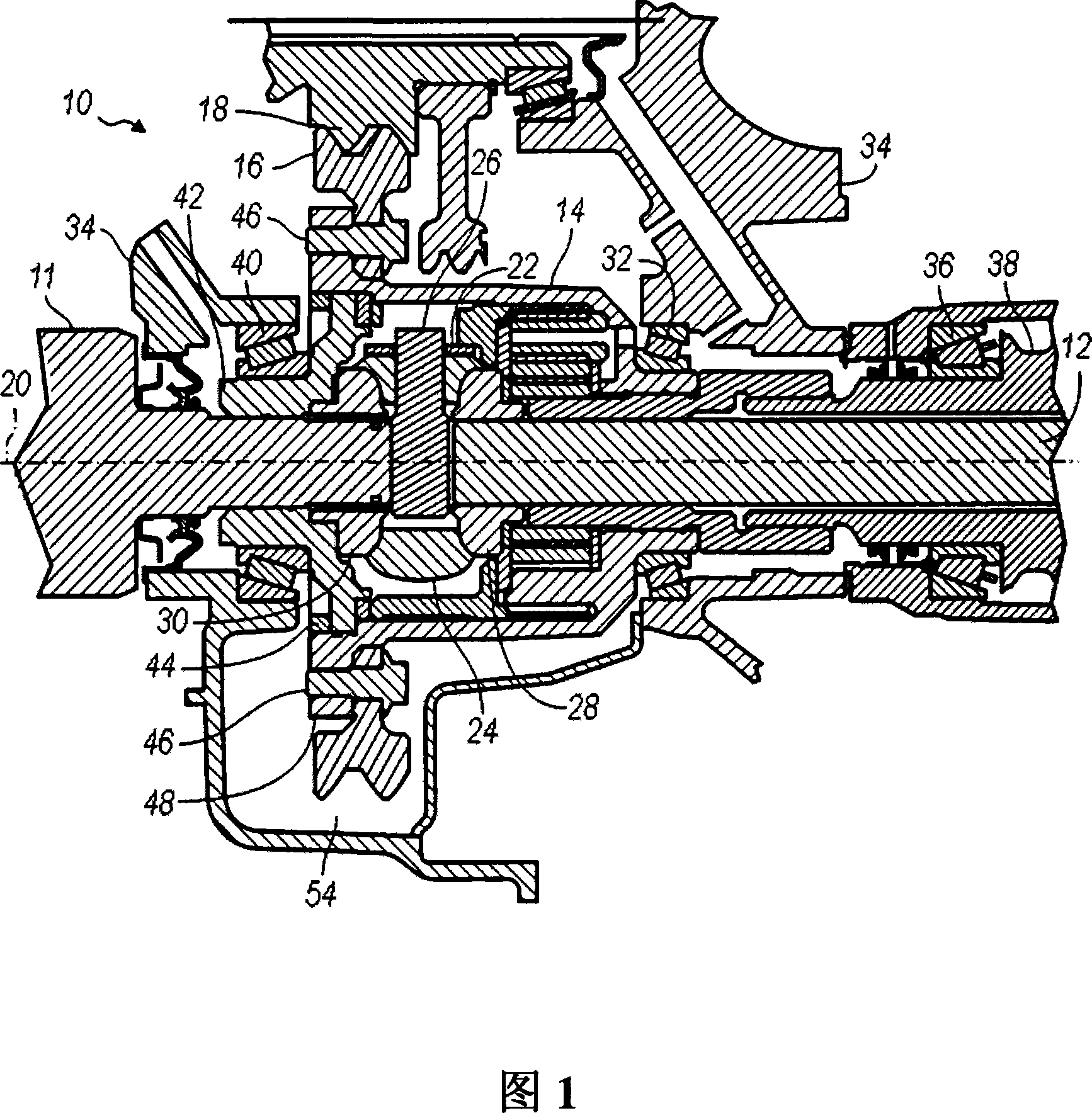

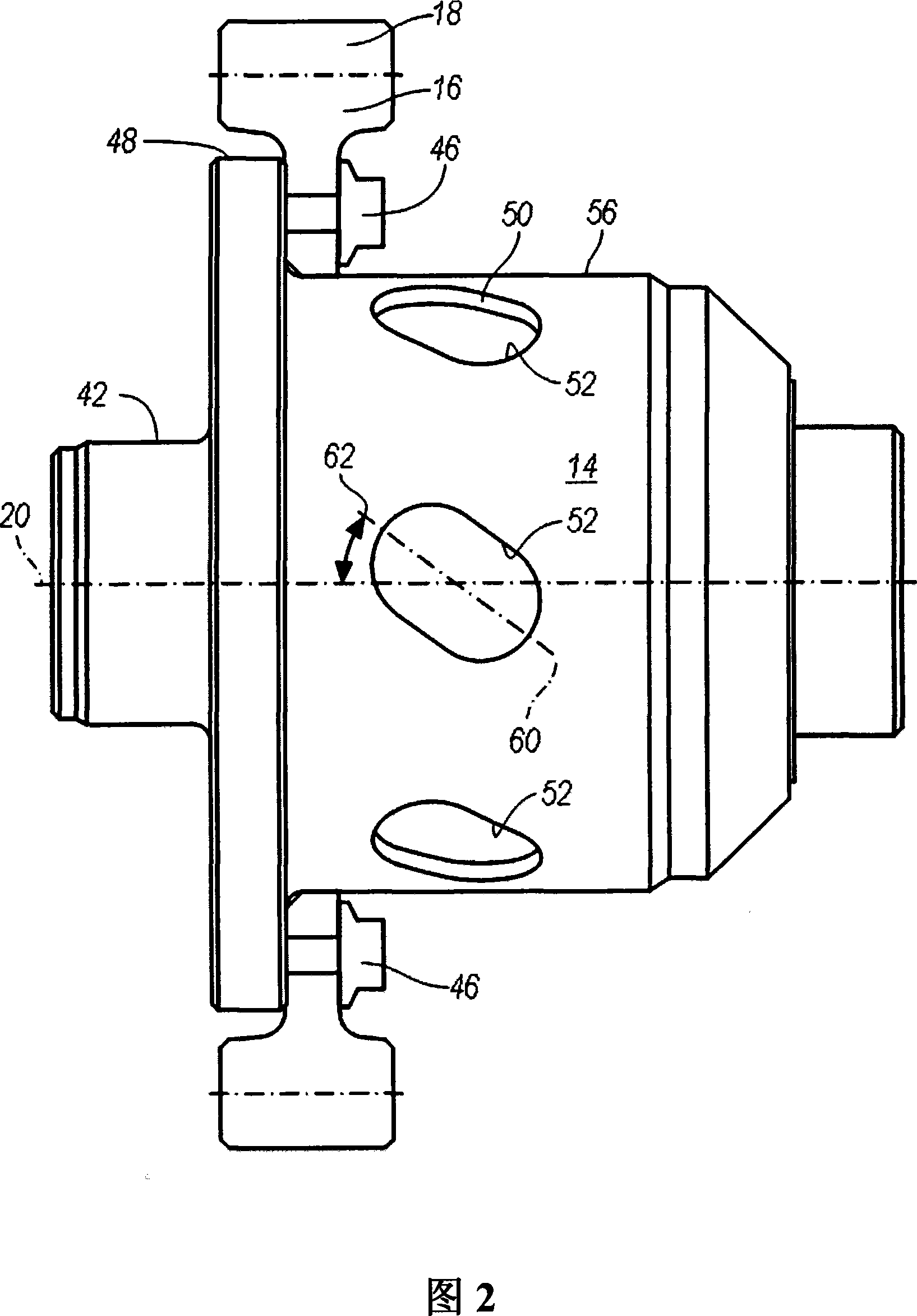

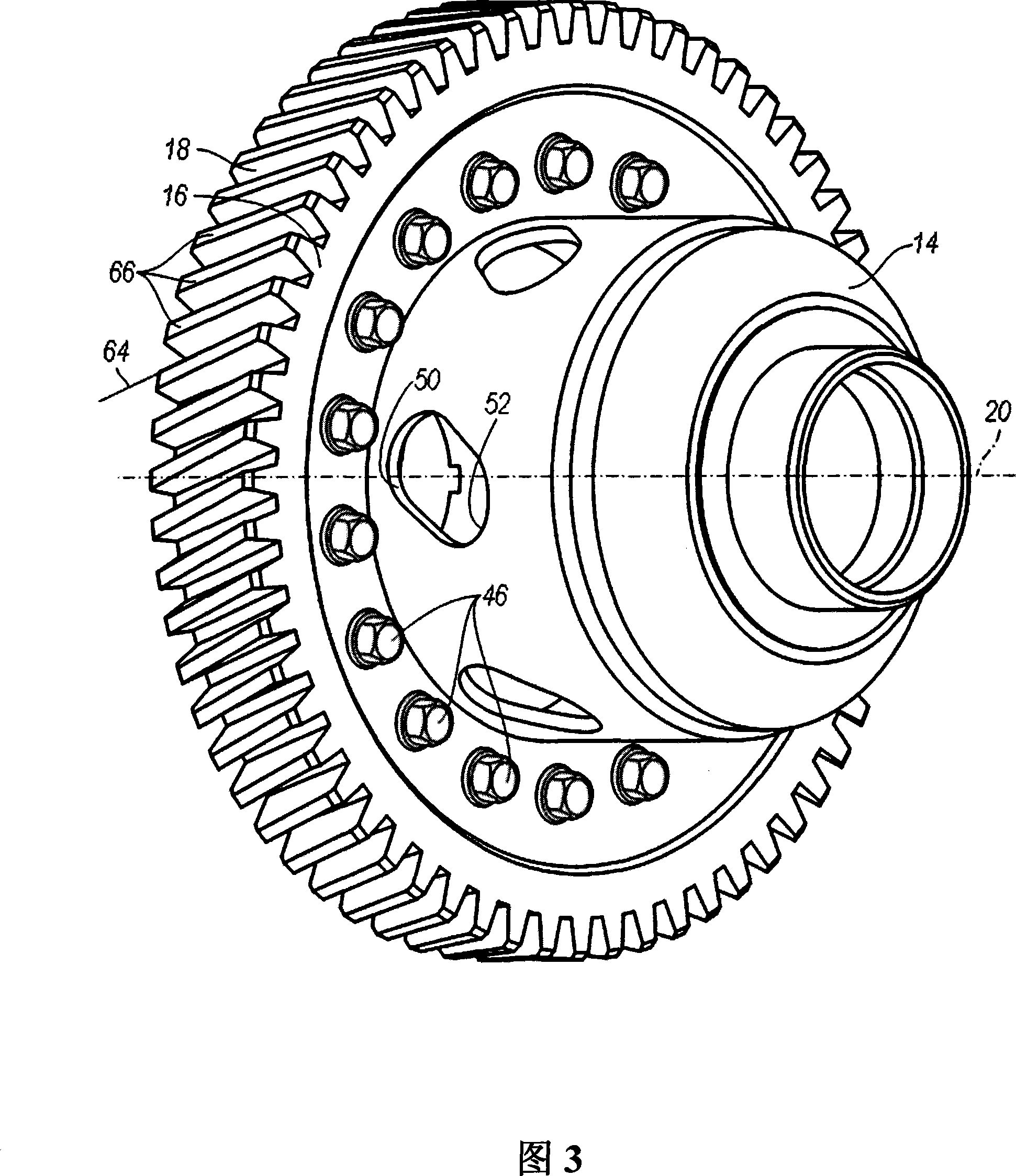

[0020] Referring first to FIG. 1 , a differential mechanism 10 for differentially transmitting torque in the form of rotational power to left and right half shafts 11 includes a housing 14 made of metal, preferably cast iron, and a housing 14 made of metal, preferably cast iron. Helical gear teeth 18 form and are drivably connected to ring gear 16 of an external power source. Ring gear 16 , housing 14 and half shafts 11 , 12 rotate about a first axis 20 . Bevel pinions 22 , 24 are drivably connected to housing 14 by shafts, revolve about axis 20 , and rotate about the axis of shaft 26 . The right bevel gear 28 and the left bevel gear 30 mesh continuously with the bevel pinions 22 , 24 . The side bevel gears 28, 30 are driveably connected to the right half shaft 12 and the left half shaft 11, respectively, each half shaft being drivably connected to a wheel.

[0021] The right half shaft 12 is supported to rotate on a bearing 32 and a bearing 36 , wherein the bearing 32 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com