Optical scanning device and image forming apparatus having the same

An optical device and image technology, applied in the fields of optics, image communication, electrical recording technology using charge patterns, etc., can solve problems such as breakage, obstructing the progress of light beams, and displacement of peripheral components, to prevent defects, prevent cleaning spots, and prevent trembling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

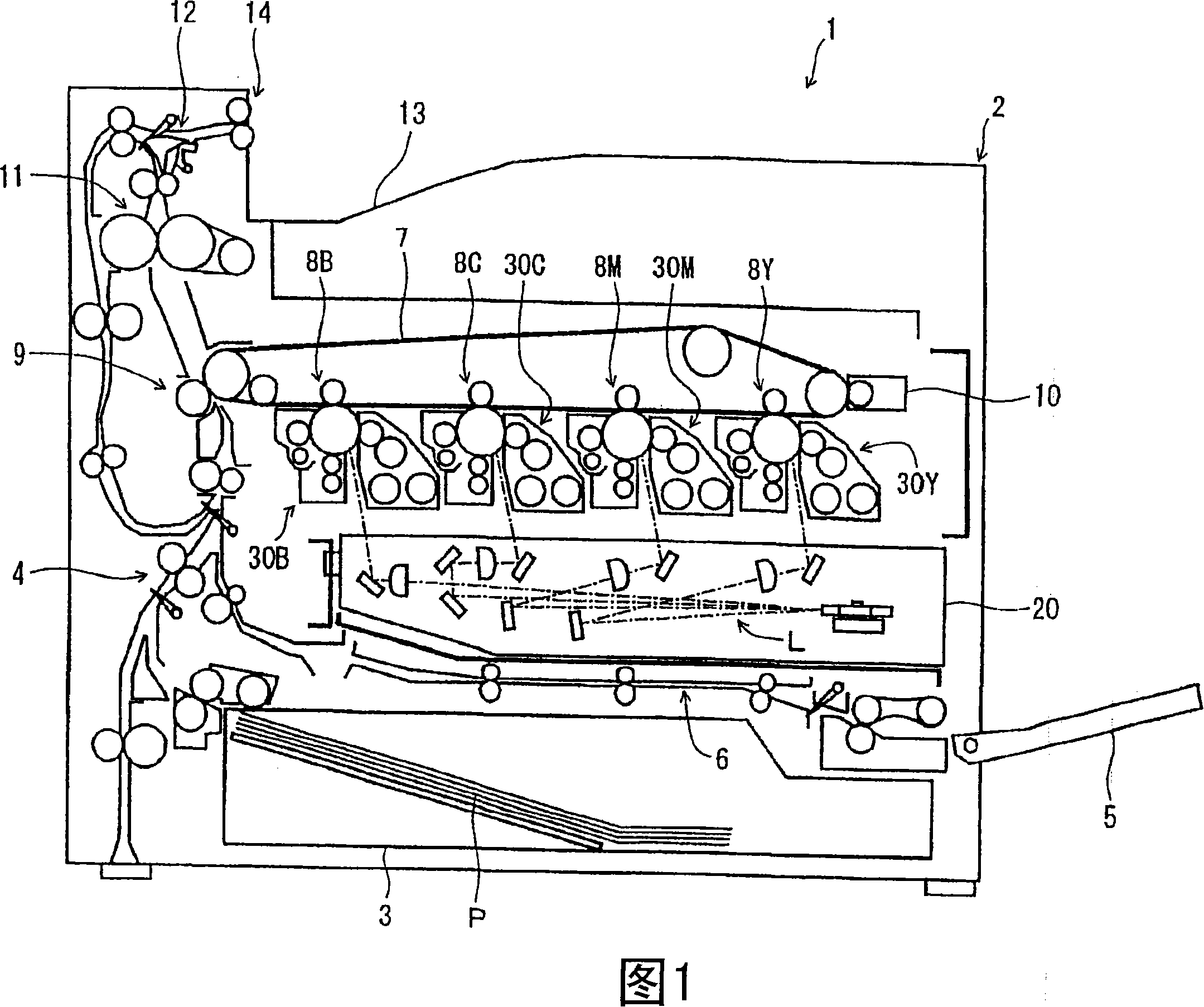

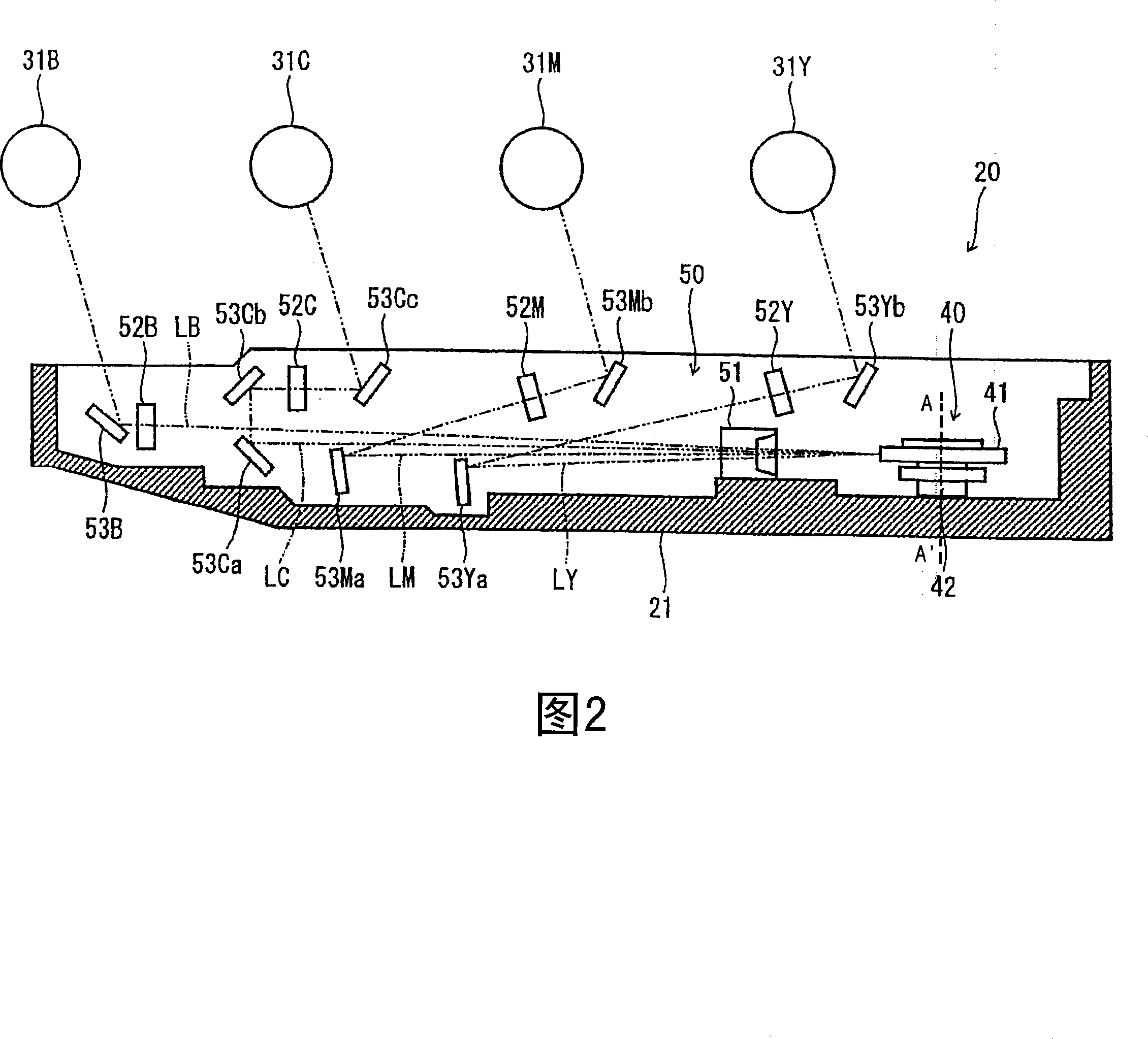

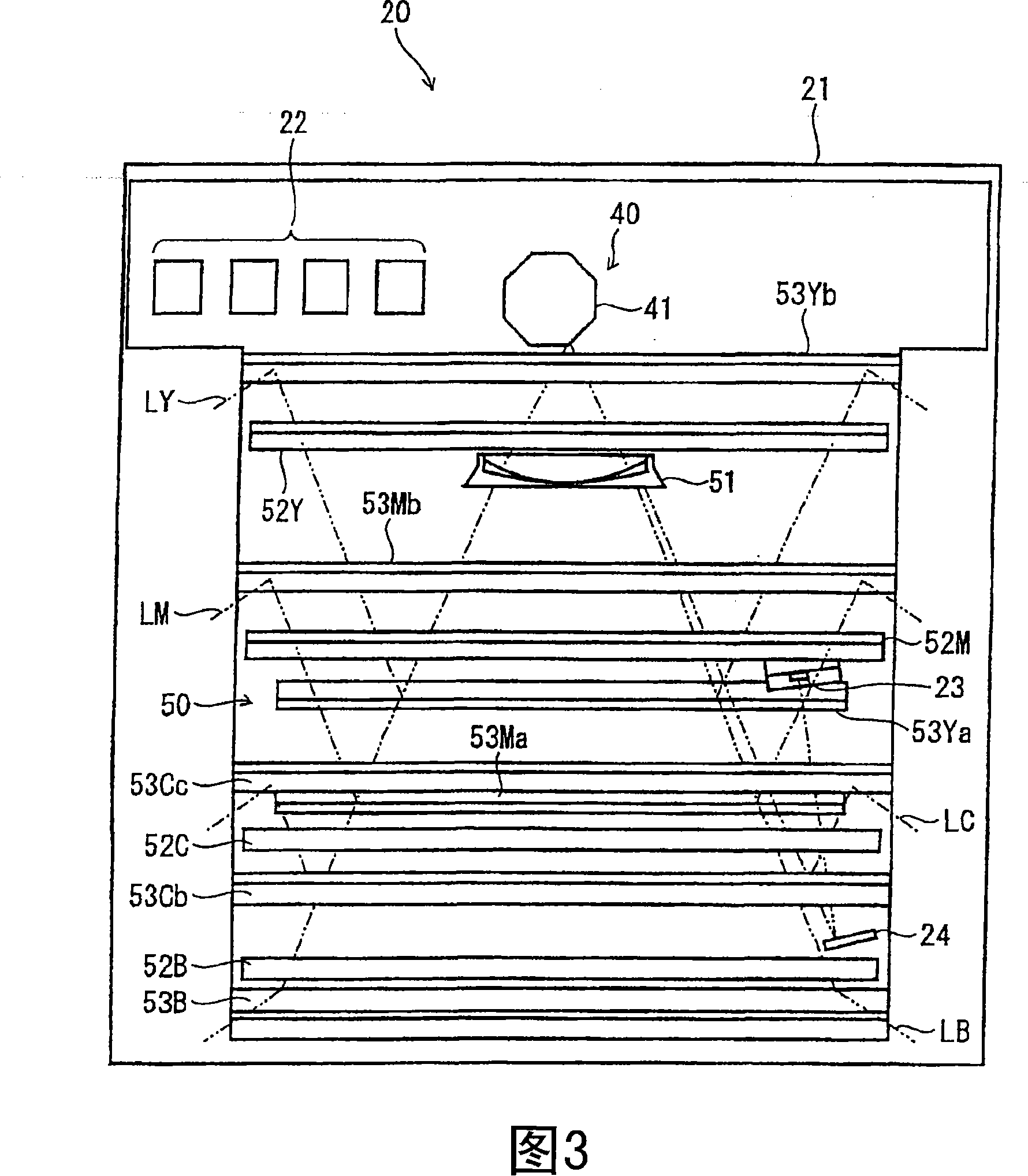

[0029] Hereinafter, embodiments of the present invention will be described with reference to FIGS. 1 to 8 . First, a schematic configuration of an image forming apparatus to which a scanning optical device according to an embodiment of the present invention is mounted will be described with reference to FIG. 1 , and an image output operation will be described. FIG. 1 is a vertical cross-sectional front view of a model of an image forming apparatus. This image forming apparatus is a color printing type apparatus that transfers a toner image onto paper using an intermediate transfer belt.

[0030] As shown in FIG. 1 , a paper cassette 3 is provided under the interior of the main body 2 of the image forming apparatus 1 . The paper cassette 3 stores and accommodates paper P such as cut paper before printing therein. Then, the sheets P are separated and fed one by one toward the upper left of the cassette 3 in FIG. 1 . The paper cassette 3 can be pulled out horizontally from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com