Turbojet engine mounting structure for aircraft

一种涡轮喷气、发动机的技术,应用在喷气式动力装置、旋翼机、飞行器等方向,能够解决增加燃料消耗、涡轮喷气发动机效率损失、阻力等问题,达到简化设计的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

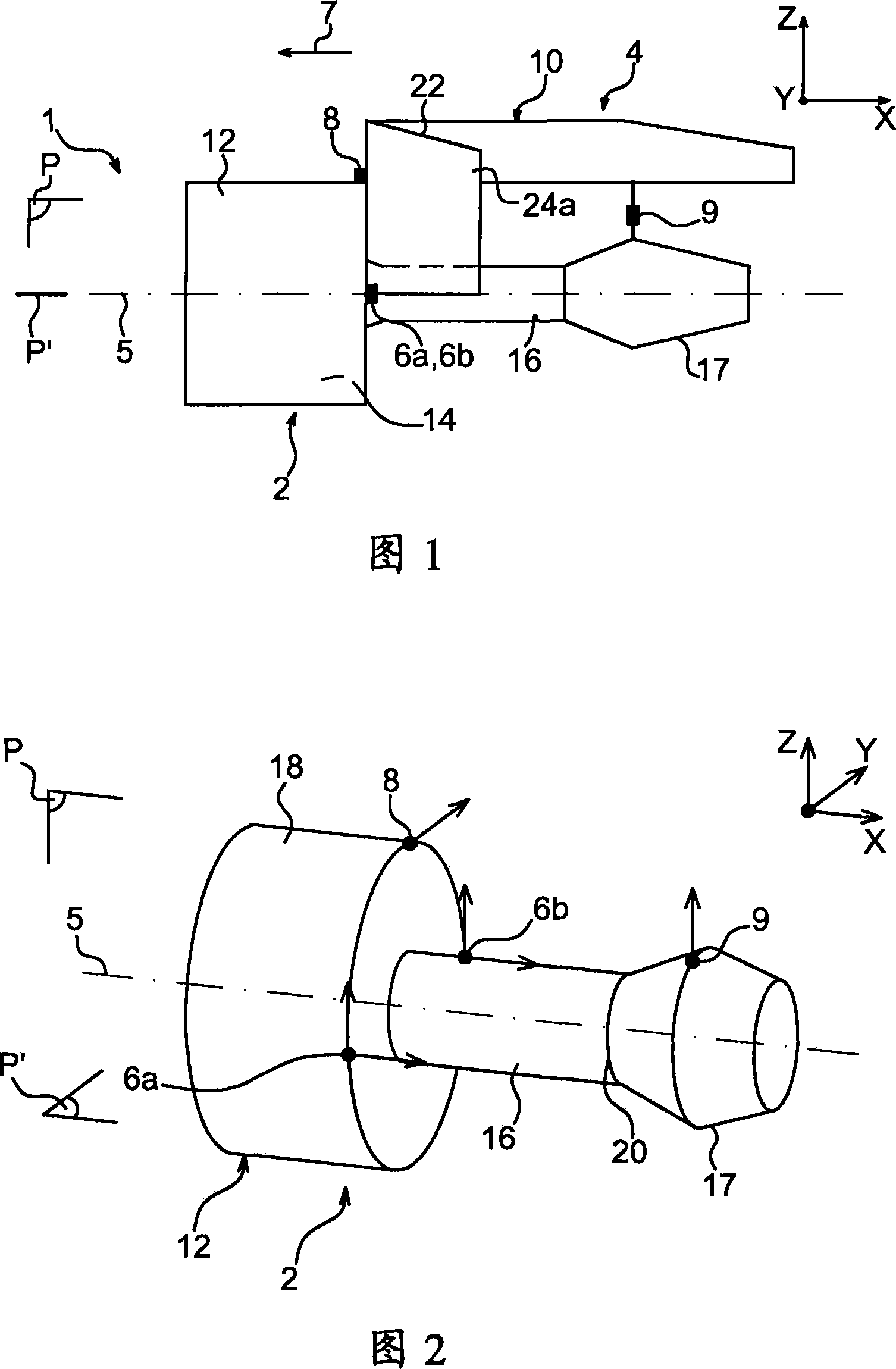

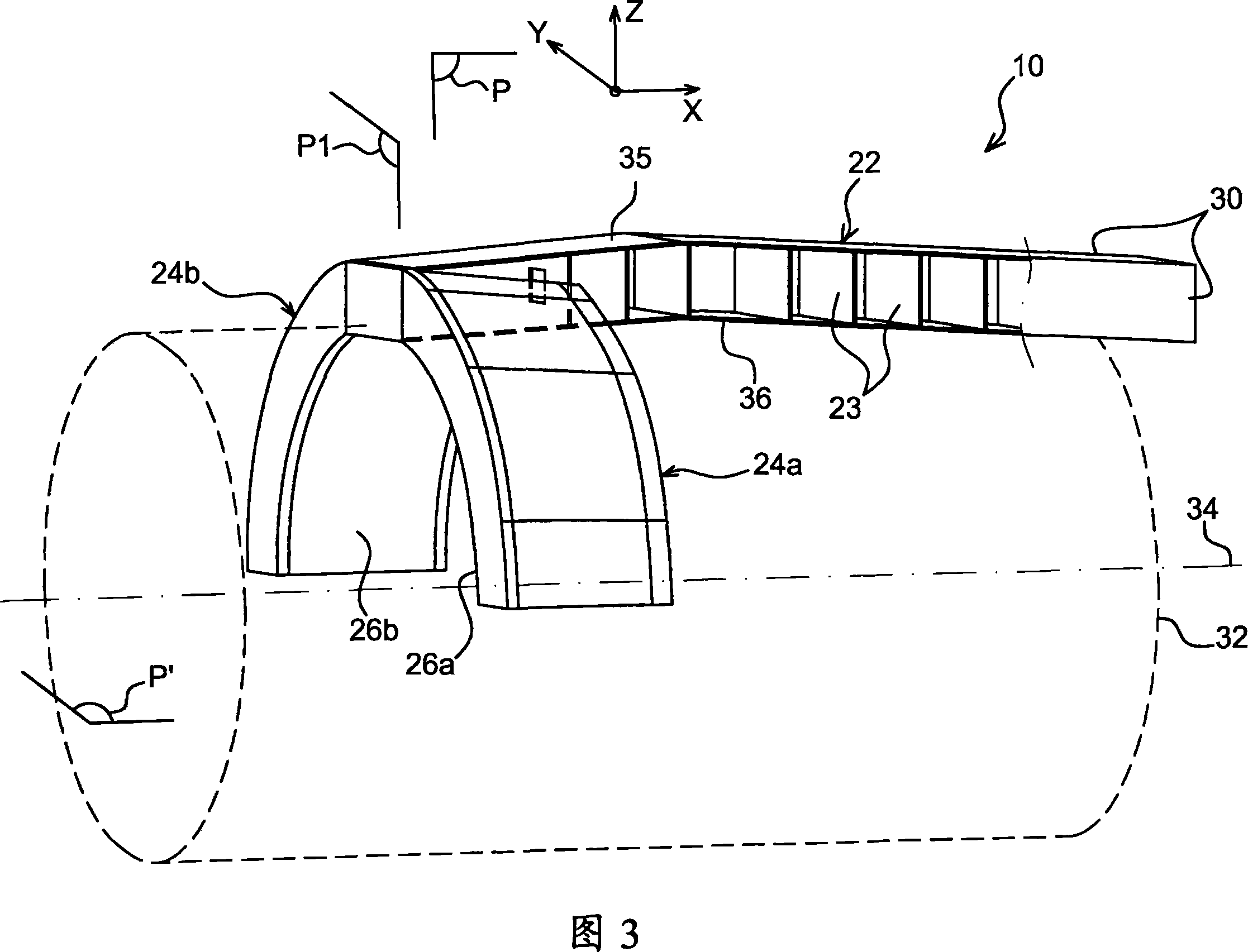

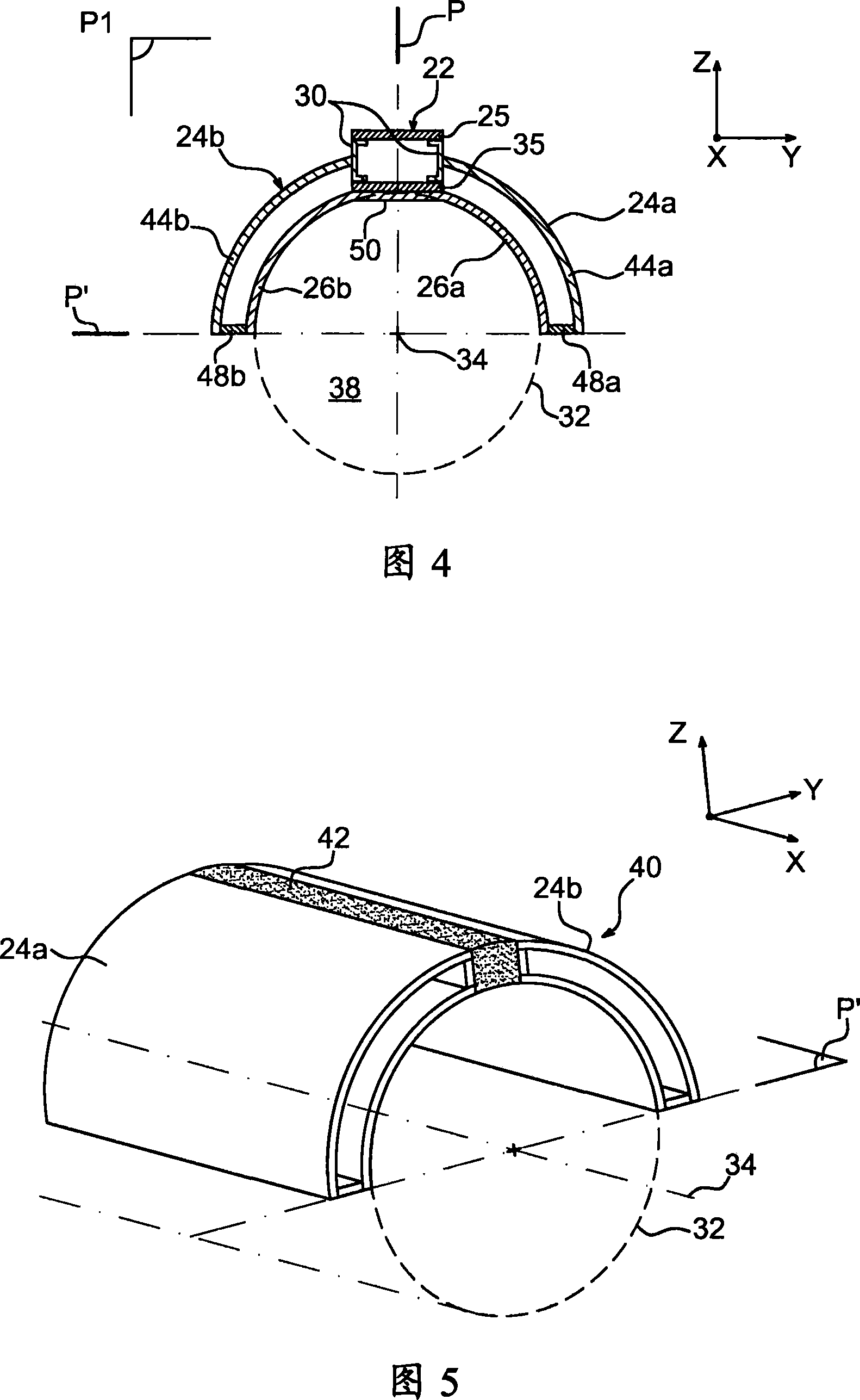

[0047] As shown in FIG. 1 , there can be seen an aircraft engine assembly 1 intended to be fixed under the wing of the aircraft (not shown), comprising an engine pylon 4 according to a first preferred embodiment of the invention.

[0048] In general, an engine assembly 1 comprises a turbojet engine 2 and a pylon 4 equipped in particular with a plurality of engine attachments 6a, 6b, 8, 9 and a rigid structure 10 to which these attachments are fixed (in Attachment 6b is covered by attachment 6a on Fig. 1). Indicatively, it is worth noting that the assembly 1 is intended to be surrounded by a nacelle (not shown), and that the pylon 4 comprises a further series of attachments (not shown) for ensuring that the assembly 1 is suspended under the wing of the aircraft.

[0049] In all the ensuing elaborations, the longitudinal direction of the pylon 4 is called X, which is also similar to the longitudinal direction of the turbojet 2 , which is parallel to the longitudinal axis 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com