Method of packaging white LED

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of long time-consuming packaging process and high temperature, and achieve the effect of improving efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

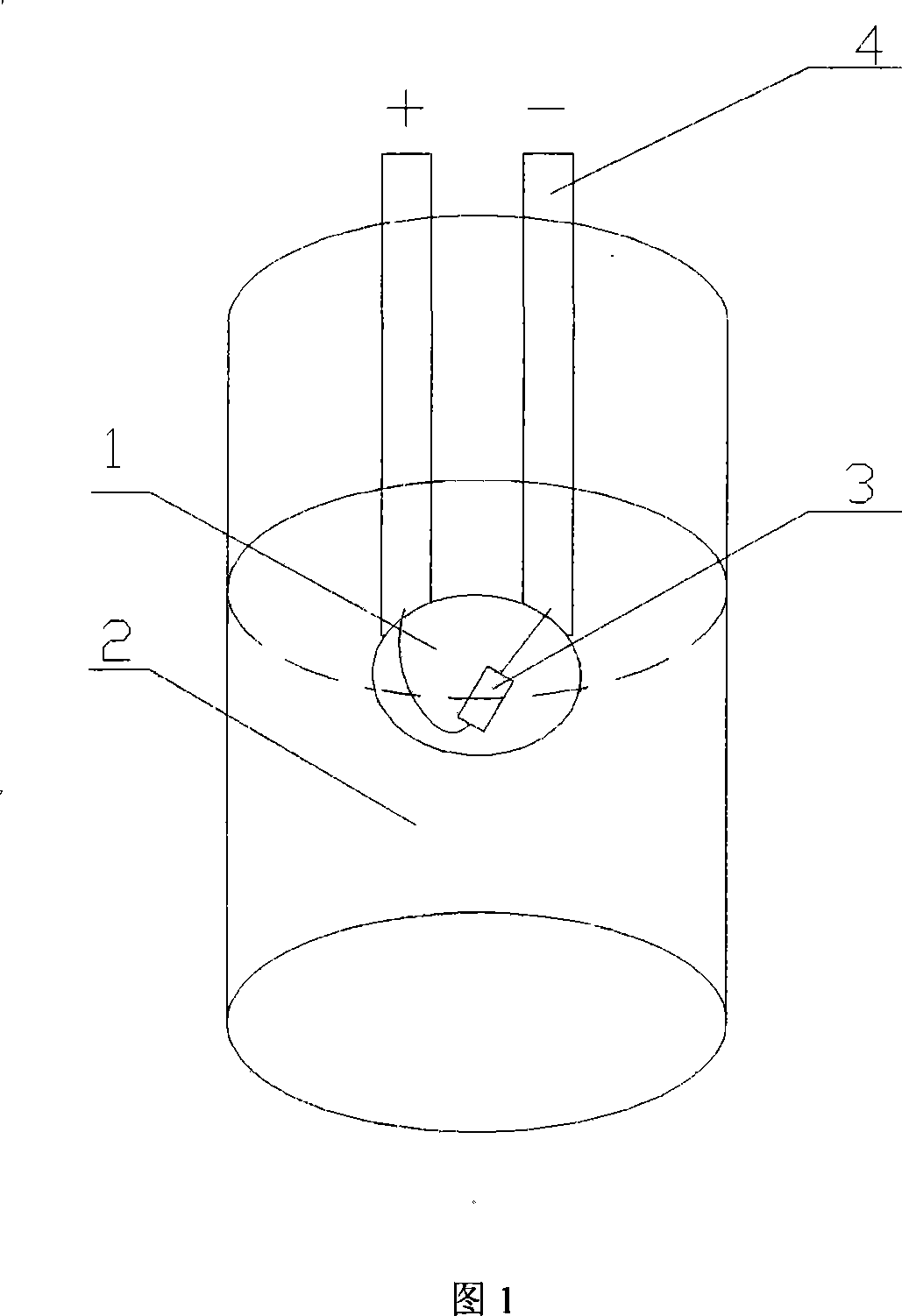

[0016] As shown in Figure 1, the packaging process of the present invention is as follows: the light-emitting diode chip 3 and its holder 1 are immersed in the photosensitive resin 2 doped or coated with phosphor and photopolymerization initiator, and the working current 4 is passed to In the light-emitting diode die 3, the light-emitting diode is made to emit light, and the photosensitive resin 2 is then excited to polymerize to encapsulate the diode chip 3 and its support 1 to finally form a light-emitting diode.

[0017] The invention realizes the adjustment of the light emission uniformity of the light emitting diode by adjusting the uniformity of the phosphor powder. The self-luminous characteristics of the light-emitting diode die can be adjusted by adjusting the light-emitting time and current of the chip, such as light-emitting uniformity, light-emitting time, light-emitting intensity, etc., so as to realize the adjustment of the uniformity of the phosphor, so that the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com