Rubber composition

A rubber composition, rubber technology, applied in the direction of tire parts, transportation and packaging, wheels, etc., can solve problems such as adhesion defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

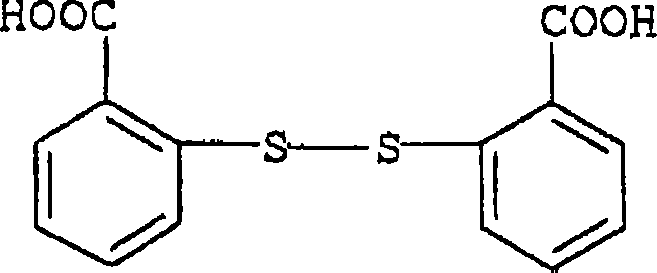

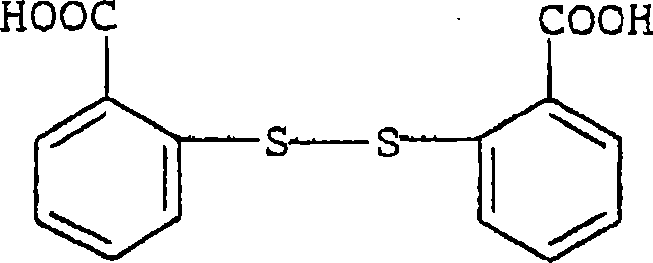

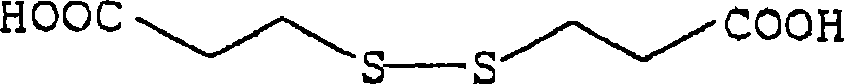

Method used

Image

Examples

Embodiment 1、 Embodiment 1-2 and comparative example 1-3

[0022] sample preparation

[0023] In each of the formulations shown in Table I, the various ingredients except the vulcanization accelerator and sulfur were mixed in a 1.5-liter internal mixer for 7.5 minutes to obtain master batches. A vulcanization accelerator and sulfur were mixed into the masterbatch by open rolls to obtain a rubber composition.

[0024] Next, the rubber composition thus obtained was vulcanized at 148° C. for 45 minutes in a mold of 15×15×0.2 cm to prepare a vulcanized rubber sheet, and then the physical properties of the vulcanized rubber were measured using the test methods shown below. The results are shown in Table I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com